Vapor permeable waterproof sheet and method for producing the same

A technology for waterproof sheet and manufacturing method, which is applied in chemical instruments and methods, synthetic resin layered products, layered products, etc. Environment, low water swelling, good water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

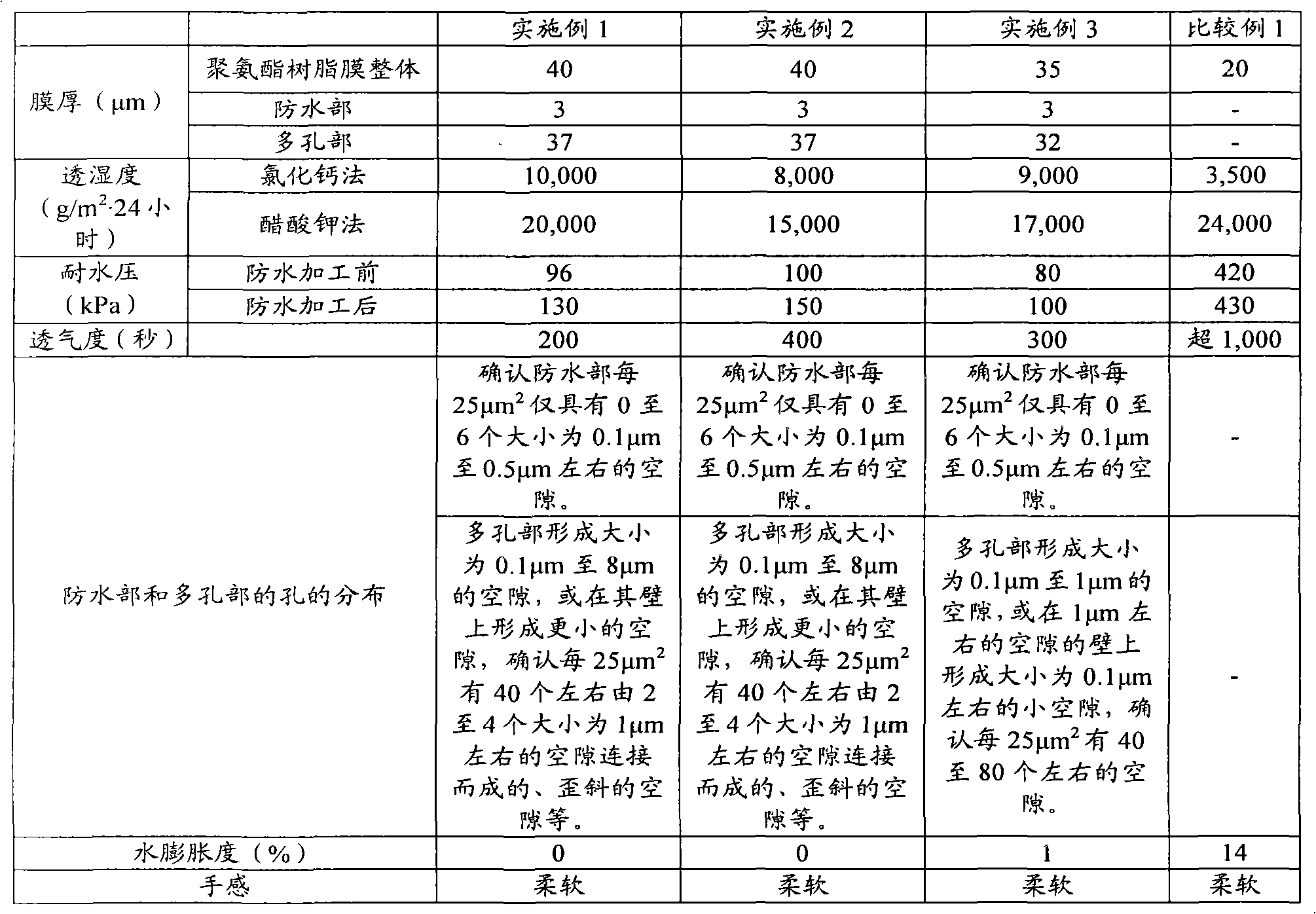

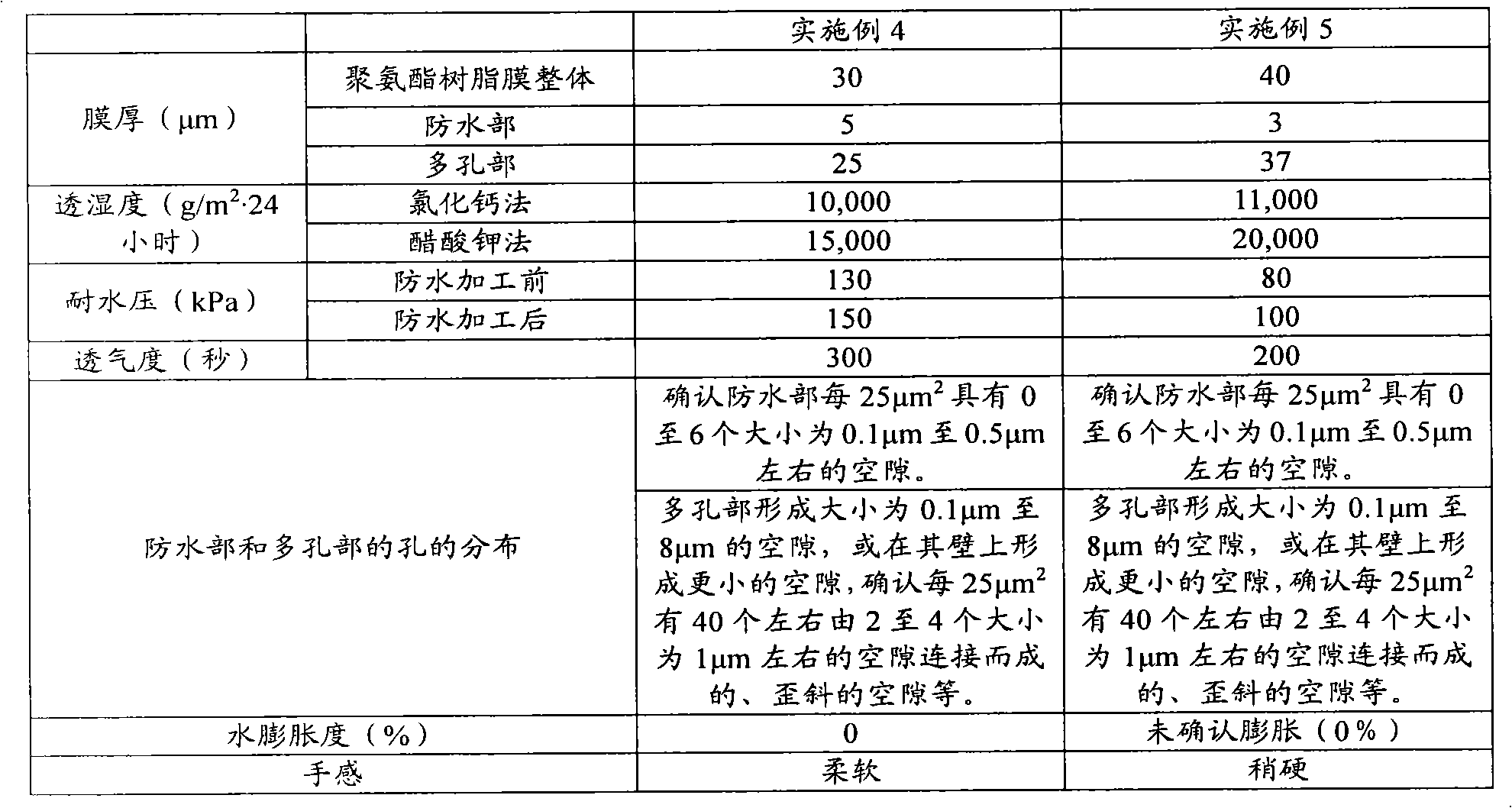

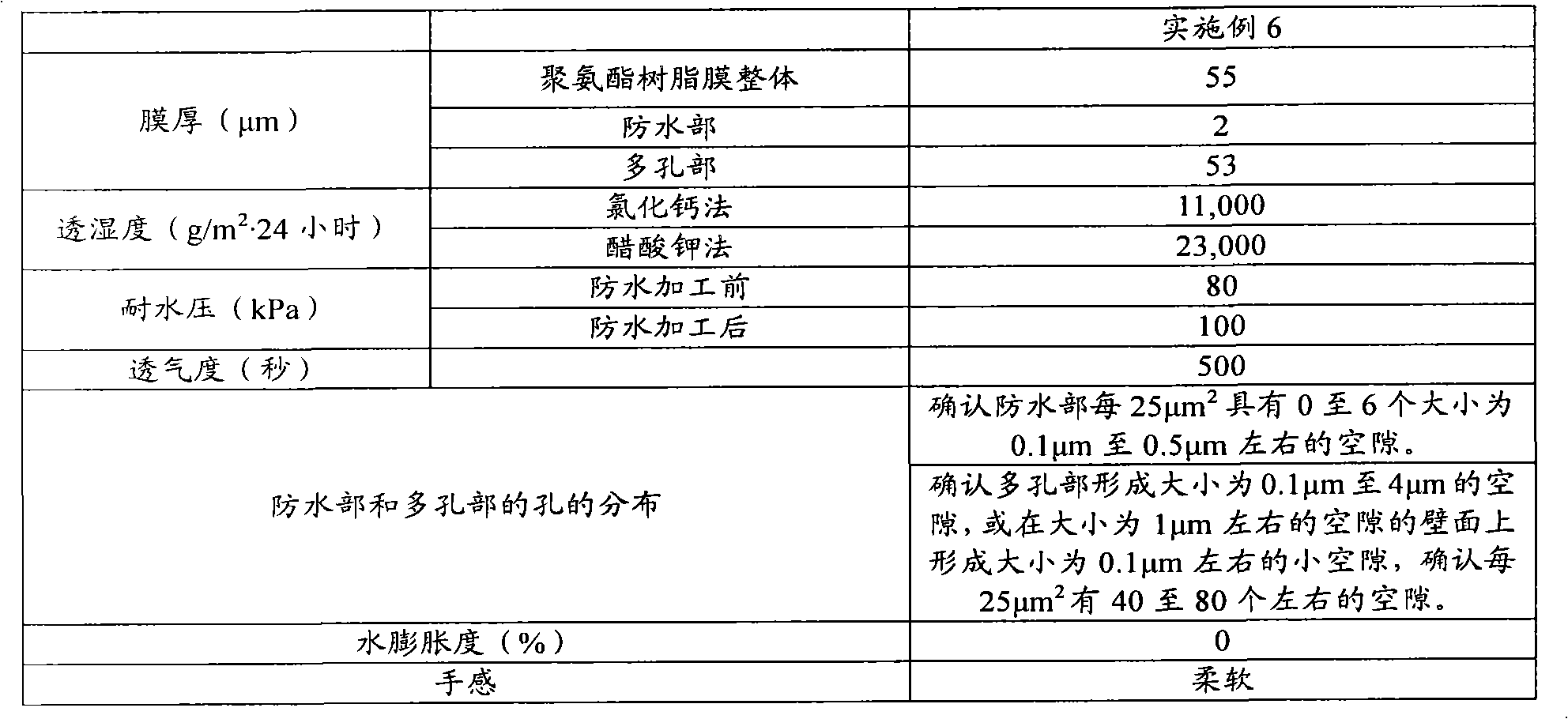

Examples

no. 1 approach

[0033] (first embodiment (aspect))

[0034] The moisture-permeable waterproof sheet according to the first embodiment of the present invention will be described.

[0035] The moisture-permeable waterproof sheet according to the present embodiment has a polyurethane resin film including a layered porous portion and a layered waterproof portion formed on at least one surface of the porous portion. That is, in this polyurethane resin film, instead of laminating the porous portion and the waterproof portion as another member, the waterproof portion and the porous portion are separately formed in layers in the polyurethane resin film.

[0036]

[0037] The polyurethane resin film includes a layered porous portion and a layered waterproof portion formed on at least one surface of the porous portion. Among them, it is preferable that one side of the polyurethane resin film is a porous part and the other side is a waterproof part.

[0038] The thickness of the polyurethane resin f...

no. 2 approach

[0087] (Second embodiment (aspect))

[0088] The moisture-permeable waterproof sheet according to the second embodiment of the present invention will be described.

[0089] The moisture-permeable waterproof sheet of the present embodiment includes the polyurethane resin film of the first embodiment and a fiber fabric laminated on one surface of the polyurethane resin film. The fiber cloth may be laminated on the polyurethane resin film via an adhesive, or directly laminated on the polyurethane resin film.

[0090]

[0091] The raw material of fiber cloth can be for example: chemical fiber, such as polyester, nylon, acrylic, polyurethane, acetate, rayon, polylactic acid, etc.; natural fiber, such as cotton, hemp, silk, wool, etc.; or their mixed fibers, Blended, interwoven, etc. Moreover, they may be in any form such as textiles, knits, non-wovens, and the like. Furthermore, a porous polytetrafluoroethylene film or the like may be laminated within the range in which the ob...

no. 3 approach

[0106] (Third embodiment (aspect))

[0107] The third embodiment of the present invention is a method of manufacturing a moisture-permeable waterproof sheet, and the following description will be given of this manufacturing method.

[0108] The method for producing a moisture-permeable waterproof sheet according to this embodiment includes: a step of applying a polyurethane resin solution to one side of a release sheet as a support to form a polyurethane resin film (hereinafter referred to as the first step); This polyurethane resin film carries out the step (hereinafter referred to as the second step) of water vapor treatment; And the step (hereinafter referred to as the second step) that the polyurethane resin coating film after water vapor treatment is immersed in water and washed with water, is dried to form polyurethane resin film third step).

[0109] [first step]

[0110] Examples of the release sheet used in the first step include: release fiber fabrics (textiles, kn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com