Pressure-sensitive adhesive tape for the protection of photo masks

A technology of adhesive tape and photomask, which is applied in the direction of originals for photomechanical processing, adhesives, film/sheet adhesives, etc., which can solve the problem of insufficient bonding ability of the release layer, machine stop, and difficult and other problems, to achieve the effect of excellent re-peelability, improved adhesion, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

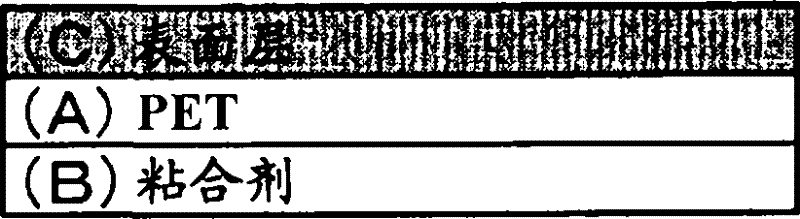

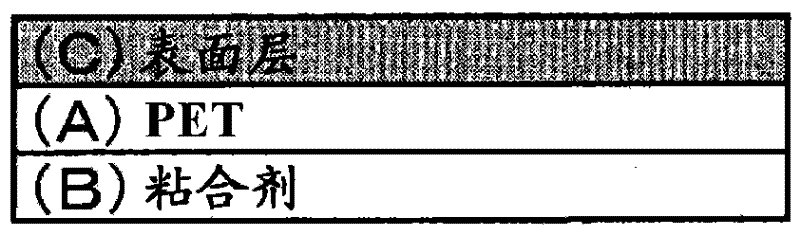

[0153] Dilute an isocyanate-crosslinked acrylic adhesive ("SKDyne 1425" manufactured by Soken Chemical Co., Ltd.) with toluene to a solid content concentration of 10% by weight, and apply it to a separator (manufactured by LINTEC Corporation) with a thickness of 25 μm. ) after drying at 120°C for 30 seconds, thereby setting an adhesive layer with a thickness of 5 μm after drying, wherein the separator is formed on one side of the PET base material with a silicone release layer Partition of the agent layer. Subsequently, the above-mentioned adhesive layer was laminated on a biaxially oriented transparent PET base material film ("F53#6C" manufactured by Toray Corporation) having a thickness of 6 µm to prepare an adhesive tape.

[0154] Subsequently, corona treatment was performed on the surface of the transparent PET base material of the above-mentioned adhesive tape using "Mixed Solution No. 48.0 for Surface Wetting Tension Test" manufactured by Wako Pure Chemical Industries, L...

Embodiment 2

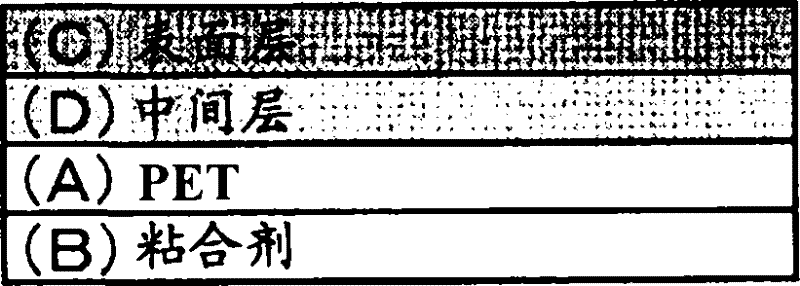

[0156] On the upper surface of the adhesive tape made by corona treatment in the same manner as in Example 1, an intermediate layer was provided as follows: Silicone resin (Silicone Resin, Toray Dowcorning Co., Ltd.) was used as a silicone resin with MEK A mixture of 60 parts by weight of "SR2410" manufactured by the company and 40 parts by weight of a methylol-type methylated melamine resin ("Cymel 370" manufactured by Mitsui Cytec Corporation) as a melamine resin was diluted to a solid content concentration of 5% by weight and After coating, drying was carried out at 130° C. for 120 seconds to obtain an intermediate layer having a thickness of 0.1 μm after drying and composed of a silicone-based resin and a melamine-based resin.

[0157] On the upper surface of the above intermediate layer, an adhesive tape for protecting a photomask was prepared as follows: 80 parts by weight of methyl triisocyanate (manufactured by Matsumoto Pharmaceutical Co., Ltd. "SI-310") with ethyl ace...

Embodiment 3

[0159] 60 parts by weight of silicone resin ("SR2410" manufactured by Toray Dowcorning Co., Ltd.) and methyl and n-butyl mixed etherified benzoguanamine (manufactured by Sanwa Chemical Co., Ltd.) "Nikalac BX-4000") 40 parts by weight of the mixture was diluted to a solid content concentration of 5% by weight and coated, and then dried at 130°C for 120 seconds to obtain a protective film with a thickness of 0.1 μm after drying. Adhesive Tape for Photomask Except for this, an adhesive tape for protecting a photomask was produced in the same manner as in Example 2. The evaluation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com