Method for producing detoxified almond oil

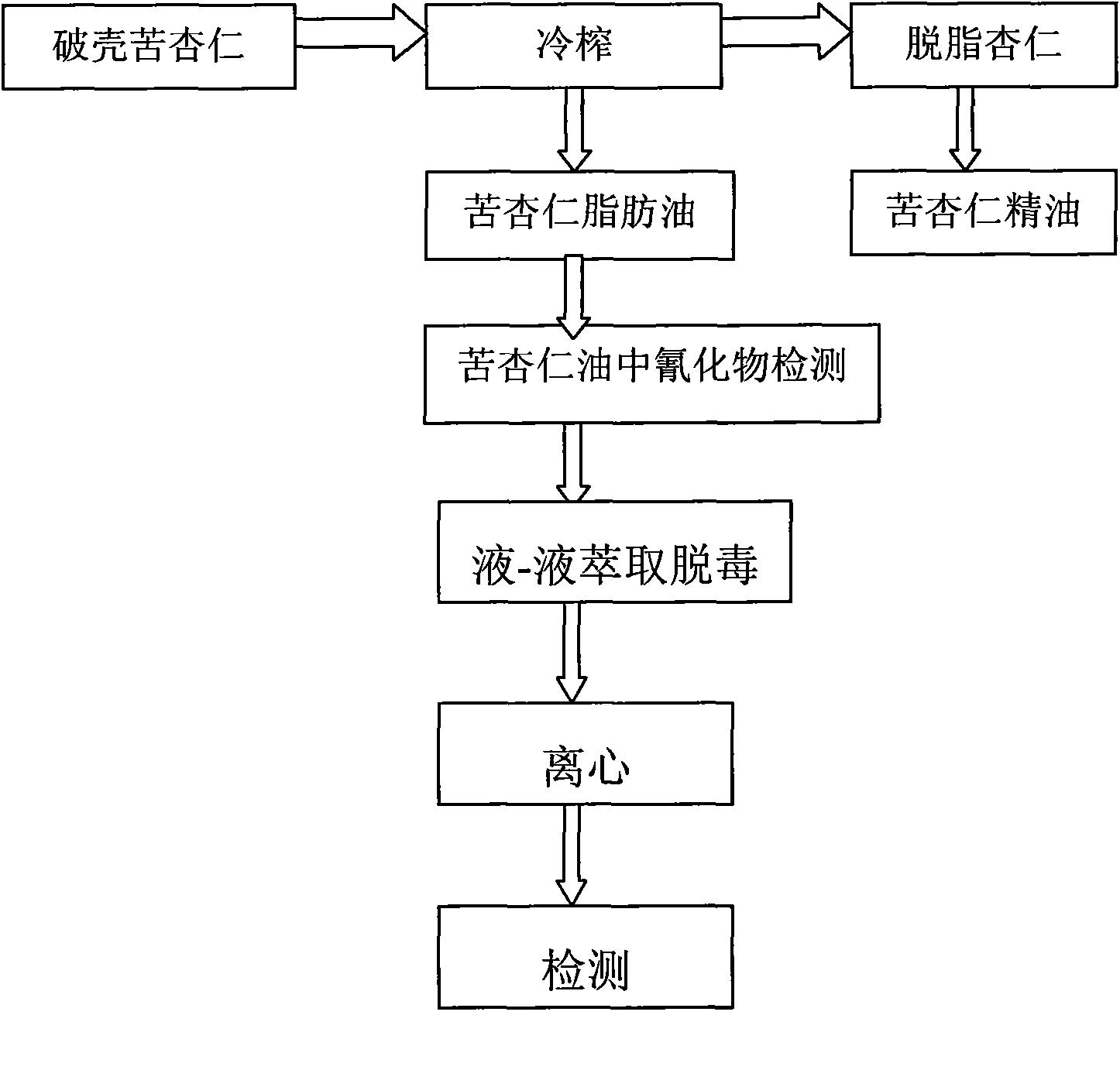

A production method and technology for almond oil, which are applied in the directions of edible oil/fat, food preparation, food science, etc., can solve the problems of the comprehensive development restriction of bitter almonds and the lack of effective removal of bitter almond oil, and achieve a solution to detoxification and methods. The effect of simplicity and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Bitter almonds are obtained by cracking the shells of bitter almond seeds, and pressed at room temperature (20-28° C.) to obtain bitter almond fat oil and defatted bitter almonds. Measure the content of 7 mg / kg cyanide in bitter almond fat oil, estimate the cyanide content of the detoxified bitter almond oil obtained by final washing is less than 0.2 mg / kg, need to extract 4 times.

[0030] Measure 100ml of bitter almond fat oil containing cyanide, add 400ml of drinking water, stir at a speed of 500 rpm for 10 minutes, then let stand for 10 minutes, remove the water phase, separate the oil phase and the water phase; The phase was centrifuged at 8000 rpm for 10 minutes.

[0031] Take 10g of the oil phase (supernatant) for detection, and continue to treat the remaining oil phase in the same way: extract with 4 times the volume of water, then centrifuge at low speed (500 rpm) and high speed (8000 rpm) to separate the oil phase and water Phase, repeat 3 times.

[0032] Ut...

Embodiment 2

[0036] Bitter almonds are obtained by cracking the shells of bitter almond seeds, and pressed at room temperature (20-28° C.) to obtain bitter almond fat oil and defatted bitter almonds. The content of cyanide in the bitter almond fat oil was measured to be 2.4549 mg / kg, and it is estimated that the cyanide content of the detoxified bitter almond oil obtained by washing in the end reaches 0.06 mg / kg, which needs to be extracted 4 times.

[0037] Measure 100ml of bitter almond fat oil that contains cyanide, add 6 times of volume (600ml) drinking water, stir at a rotating speed of 550 rpm for 20 minutes, and then let stand for 10 minutes, remove the water phase, and separate the oil phase and the water phase; The resulting oil phase was then centrifuged at 9000 rpm for 15 minutes.

[0038] Take 10 g of the oil phase (supernatant) for detection, and continue to process the remaining oil phase in the same way, repeating 4 times. Utilize above-mentioned embodiment to process conta...

Embodiment 3

[0042] Compared with Examples 1 and 2, the difference of this example is that the separation process of the oil phase and the water phase after water washing and extraction is different. In this example, the obtained first extraction oil phase is continuously extracted, and then centrifuged, which is relatively economical. amount of extraction water.

[0043] Get 100mL of bitter almond fat oil containing cyanide, add 4 times the volume (400ml) of drinking water, stir at a speed of 550 rpm for 10 minutes, and then let stand for 10 minutes to remove the water phase; Add 400ml of drinking water to the oil phase, stir at 550 rpm for 10 minutes, then let it stand for 10 minutes to remove the water phase; repeat the treatment 3 times in the same way. Centrifuge the oil phase obtained in the fourth separation at 8000 rpm, take 10 g of oil from the oil phase for testing, add the rest of the oil to 400 ml of drinking water, stir at 550 rpm for 10 minutes, then let stand for 10 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com