Hydrophilic polyfluortetraethylene microporous membrane folding type filter element

A polytetrafluoroethylene and hydrophilic technology, which is applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of small flow, low dirt holding capacity, short life, etc., and achieve high flow, Overcome fiber shedding and enhance scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

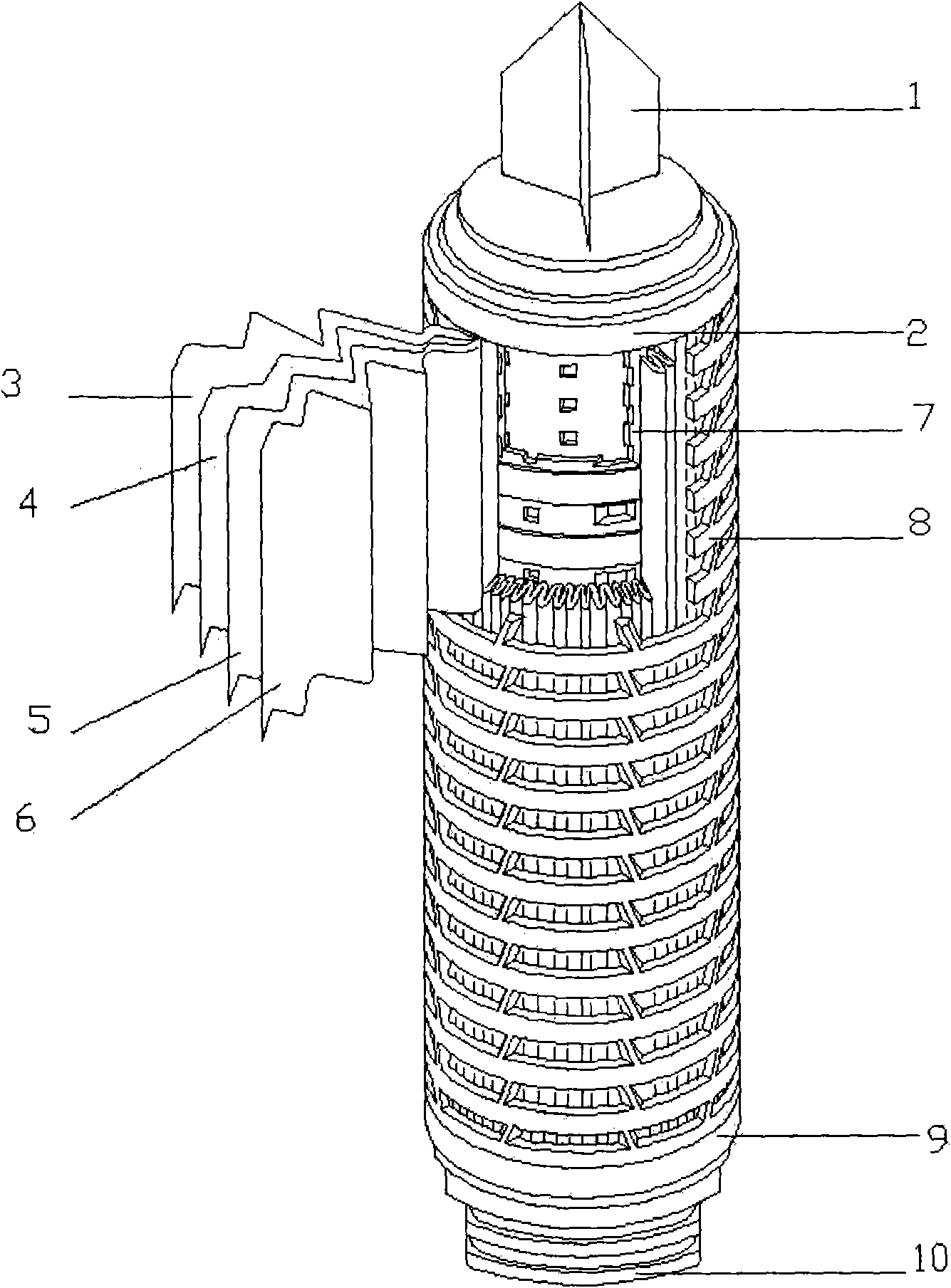

[0011] Such as figure 1 As shown, a hydrophilic polytetrafluoroethylene microporous membrane pleated filter element of the present invention is composed of a filter medium layer, an inner support cylinder 7 and an outer support cylinder 8, and the filter medium layer is folded into fins to surround On the outer circumference of the inner support cylinder 7, the folding line of the filter medium layer is parallel to the axial direction of the inner support cylinder 7, and the outer support cylinder 8 is sleeved on the outside of the cylinder formed by the filter medium layer, wherein the The filter medium layer is composed of a layer of long-fiber non-woven fabric 3, a layer of short-fiber non-woven fabric 4, a layer of polytetrafluoroethylene hydrophilic microporous filter membrane 5 and a layer of plane guide net 6. Described fine and short fiber nonwoven fabric 4 is arranged on the upstream of polytetrafluoroethylene hydrophilic microporous filter membrane 5, and described l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com