Method for using stannous oxide catalyst in esterification step in production of plasticizer

A technology of stannous oxide and plasticizer, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve many side reactions, complicated follow-up procedures, titanium Eliminate problems such as ion residues, achieve the effects of enhanced catalyst activity, saving raw material costs, and shortening the esterification cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

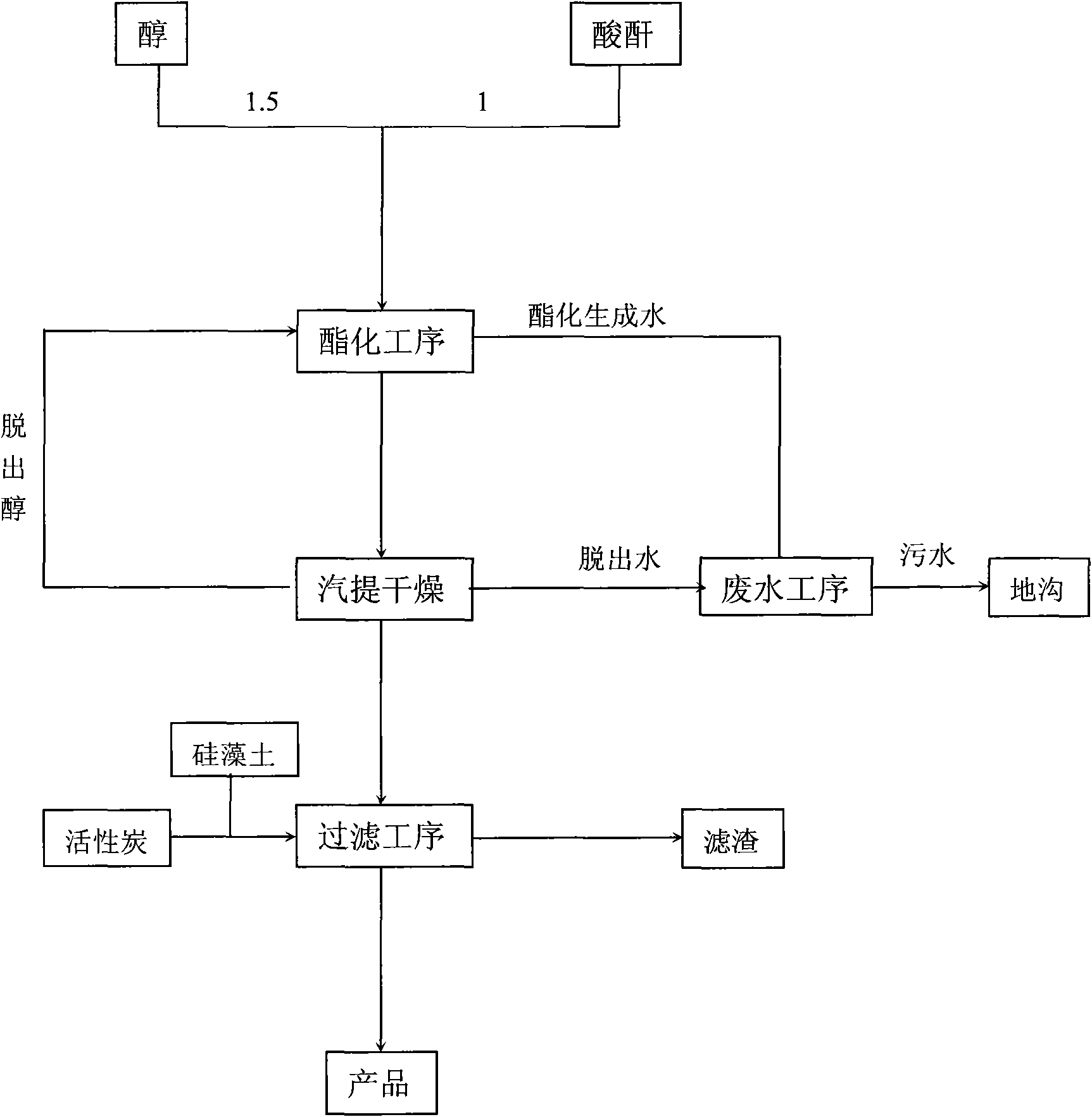

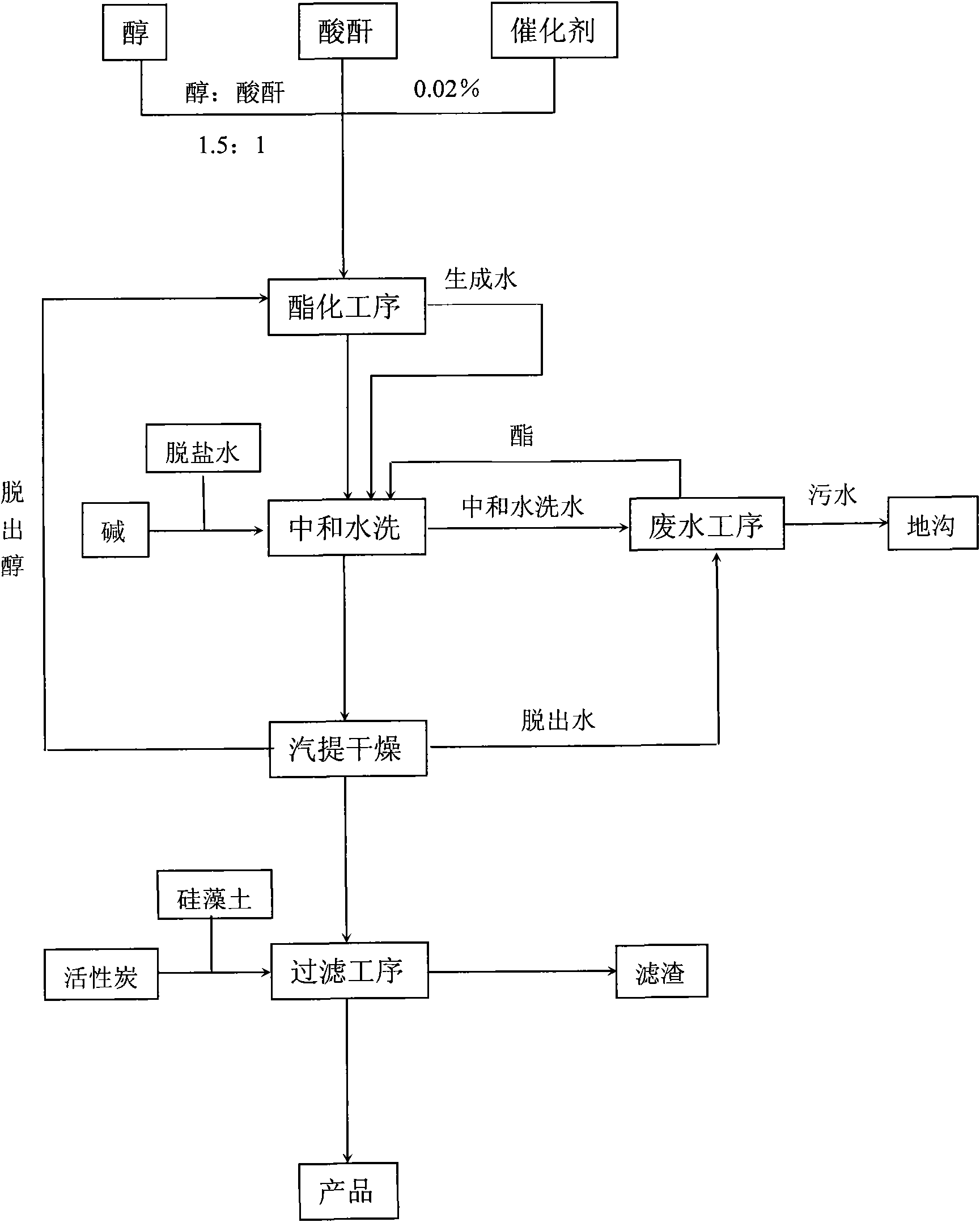

Image

Examples

Embodiment 1

[0034] Under the condition that the conditions of the reactor and the ratio of raw materials are the same, the method of the present invention is used to compare the parameters of producing DOA with the traditional process.

[0035] compared items

Embodiment 2

[0037] Under the condition that the conditions of the reactor and the ratio of raw materials are the same, the parameters of TOTM produced by the method of the present invention and the traditional process are compared.

[0038] compared items

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com