Panel rounding R angle machining abrading machine for a plane display and machining method

A flat-panel display and corner processing technology, which is applied to machine tools, metal processing equipment, and grinders suitable for grinding the edges of workpieces, which can solve the problems of waste of cycle time and long working hours, and achieve the effect of improving productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

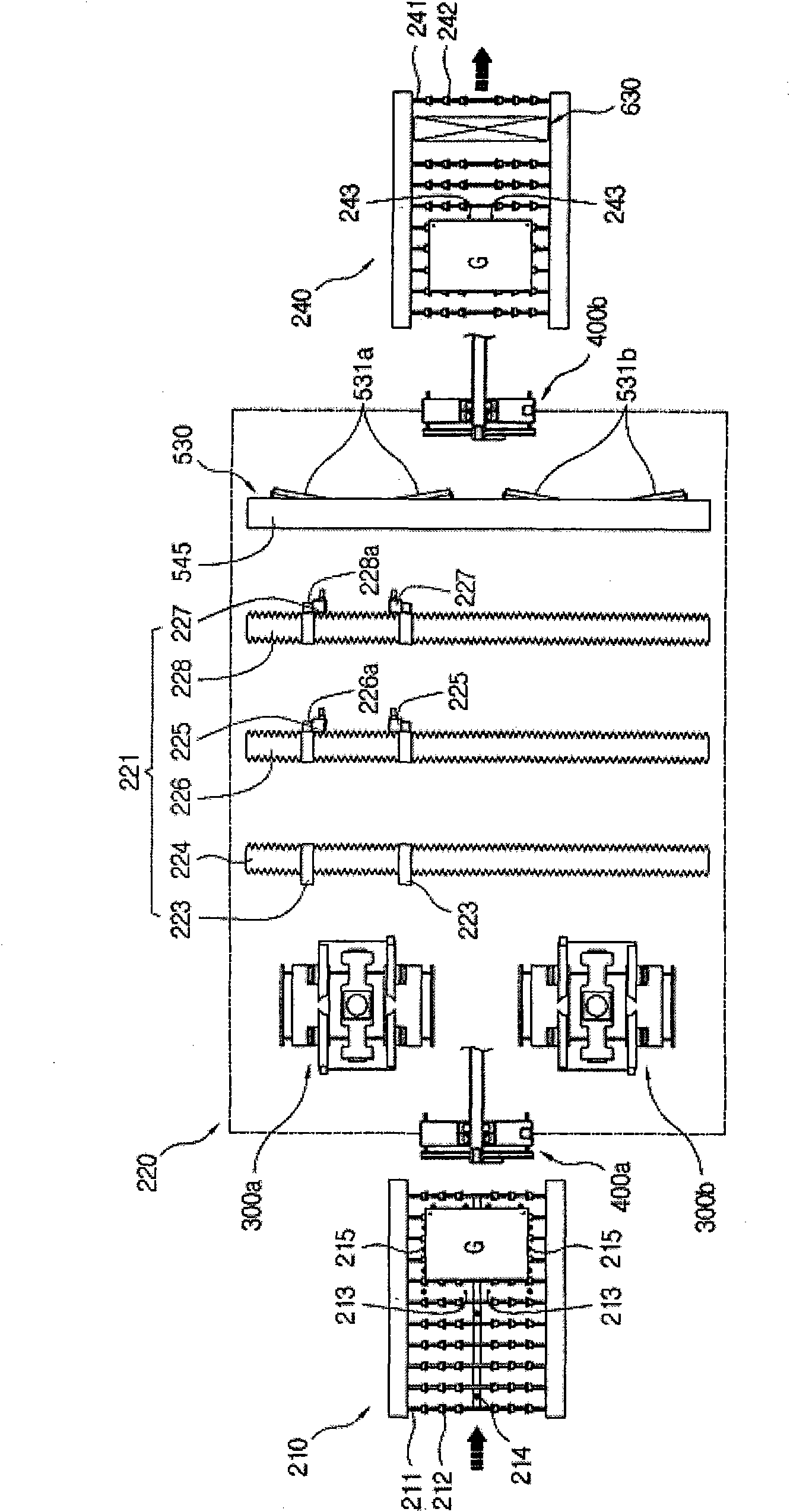

[0051] In order to allow people who read the present invention to fully understand the advantages of the present invention in action and the goals that can be achieved by implementing the present invention, it is necessary to illustrate the content of the present invention in the form of drawings, so please be sure to Refer to the attached drawings and written content.

[0052] Hereinafter, the inventor will describe in detail the form of processing expected to be achieved by the present invention with reference to the accompanying drawings. The same reference symbols are attached to each drawing, and the codes represent the same mechanisms or devices.

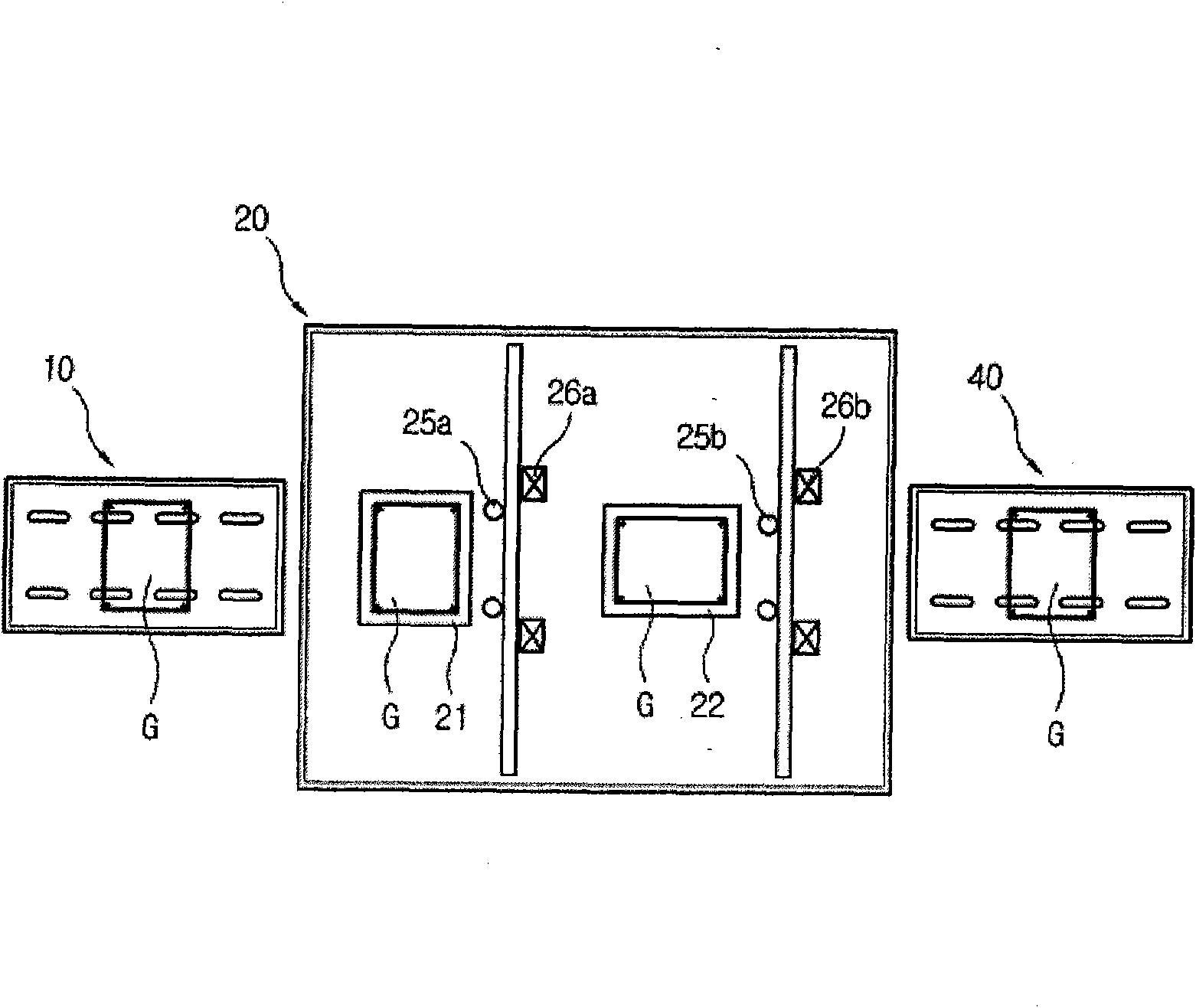

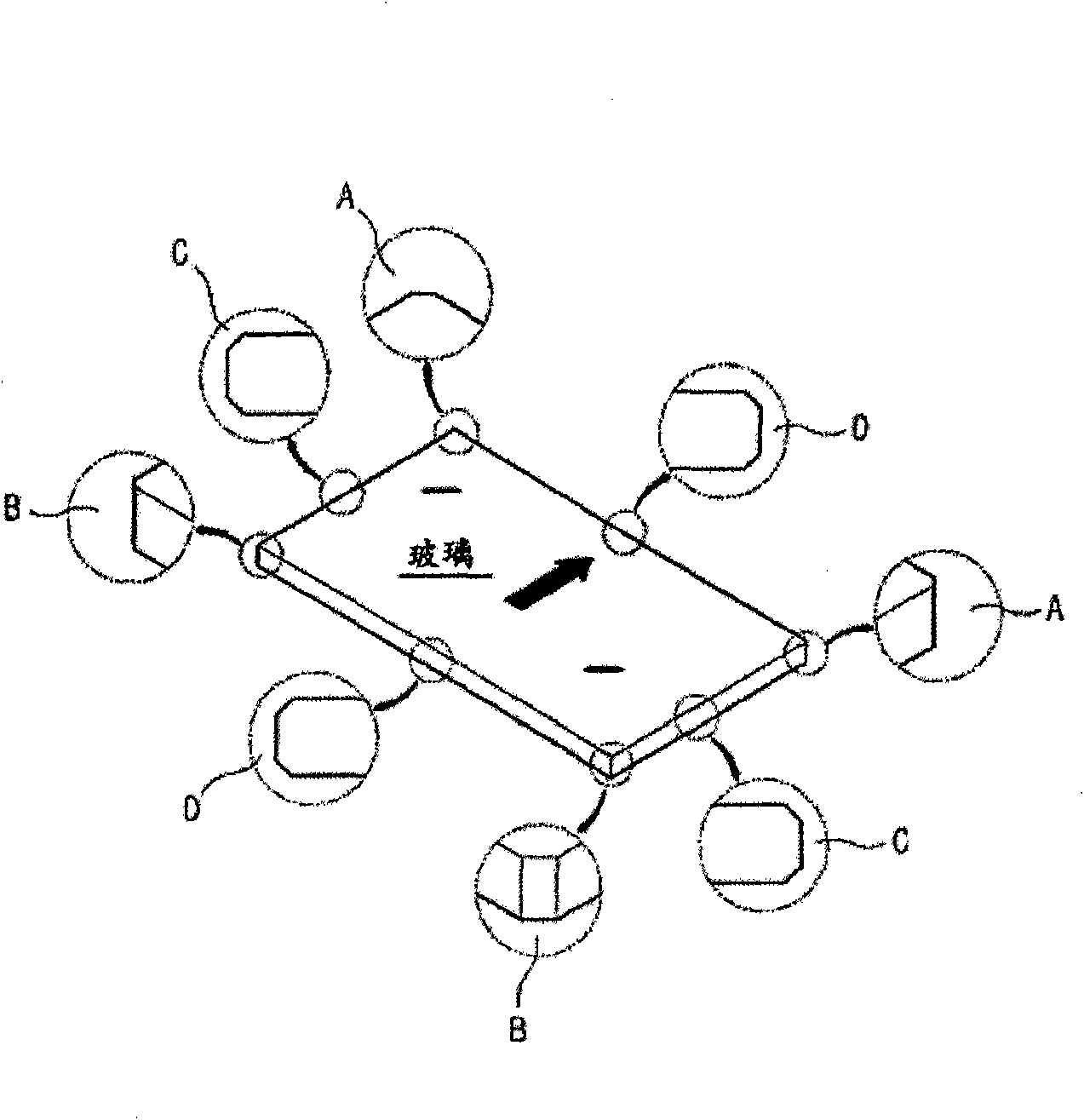

[0053] figure 2 It is a perspective view of the panel made to explain the rounded R-corner processing.

[0054] Before entering the description of the drawing, the panel described below is a TFT-LCD (Thin Film Transistor-Liquid Crystal Display) panel, and the patent scope of this invention is not limited to TFT -LCD panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com