Electric heating anti-fog mirror

An electric heating and anti-fog technology, applied in the field of anti-fog mirrors, can solve the problems of potential safety hazards, complex structure and circuit, easy aging and damage, etc., and achieve the effect of reduced volume, clear imaging and natural reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

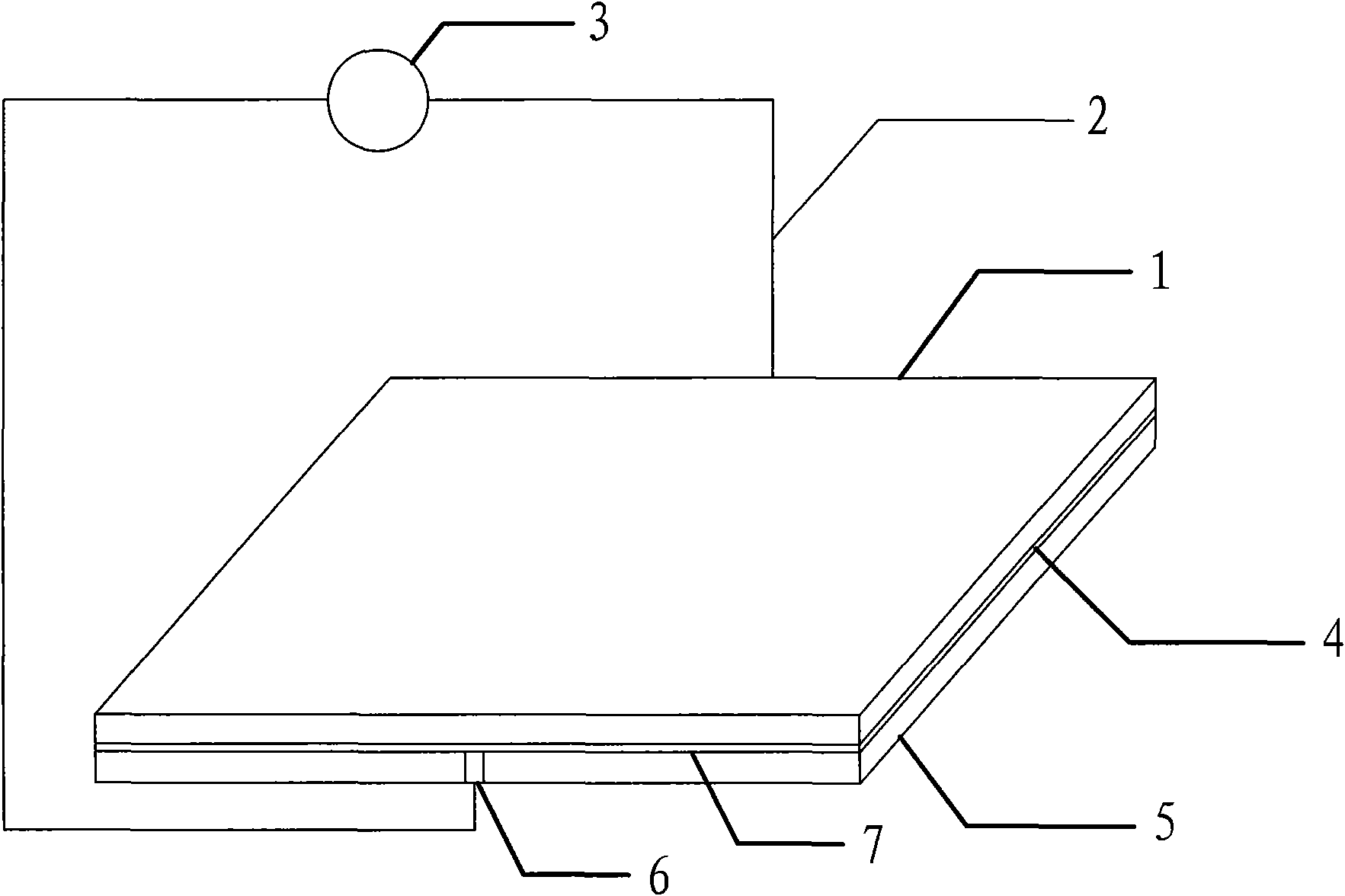

[0031] Such as figure 1 Shown, electric heating anti-fog mirror, it comprises EN intermediate film 4, is bonded mirror surface coated glass 1 and heating coated glass 5 by described EN intermediate film 4, and EN intermediate film 4 bonds described mirror surface coated glass 1, heating coating Coating of glass 5; said mirror-coated glass 1 is vacuum silver-plated glass, and said heating-coated glass 5 is nickel-plated glass; said heating-coated glass 5 is connected with copper e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com