Integrated arsenic collector

A collector and integrated technology, applied in the field of dust collection devices and devices for collecting powdery arsenic, can solve the problems of inability to stably collect arsenic products, poor temperature regulation capability of smoke and dust mixtures, etc., and achieve convenient temperature control and small resistance fluctuations. , The effect of long service life of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

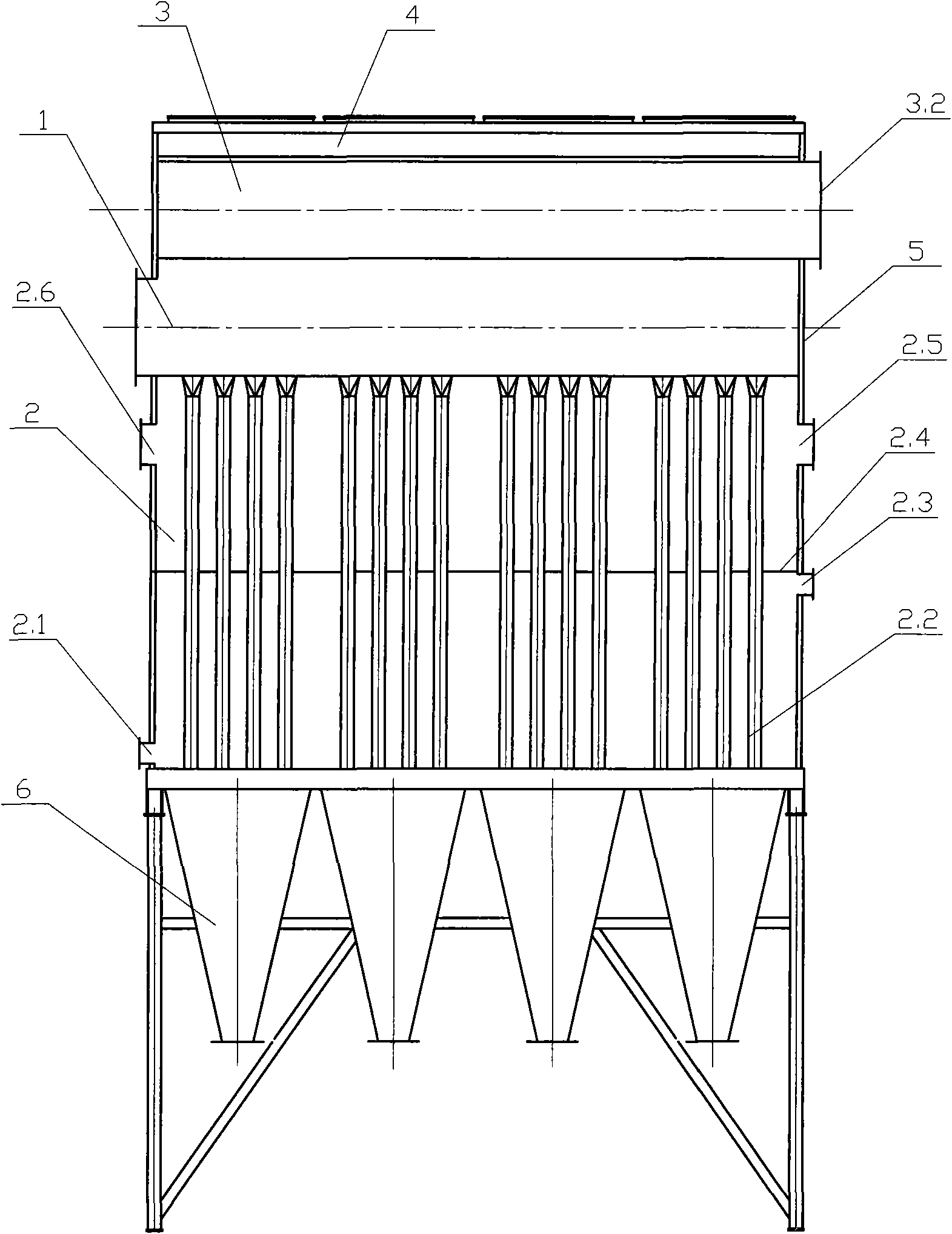

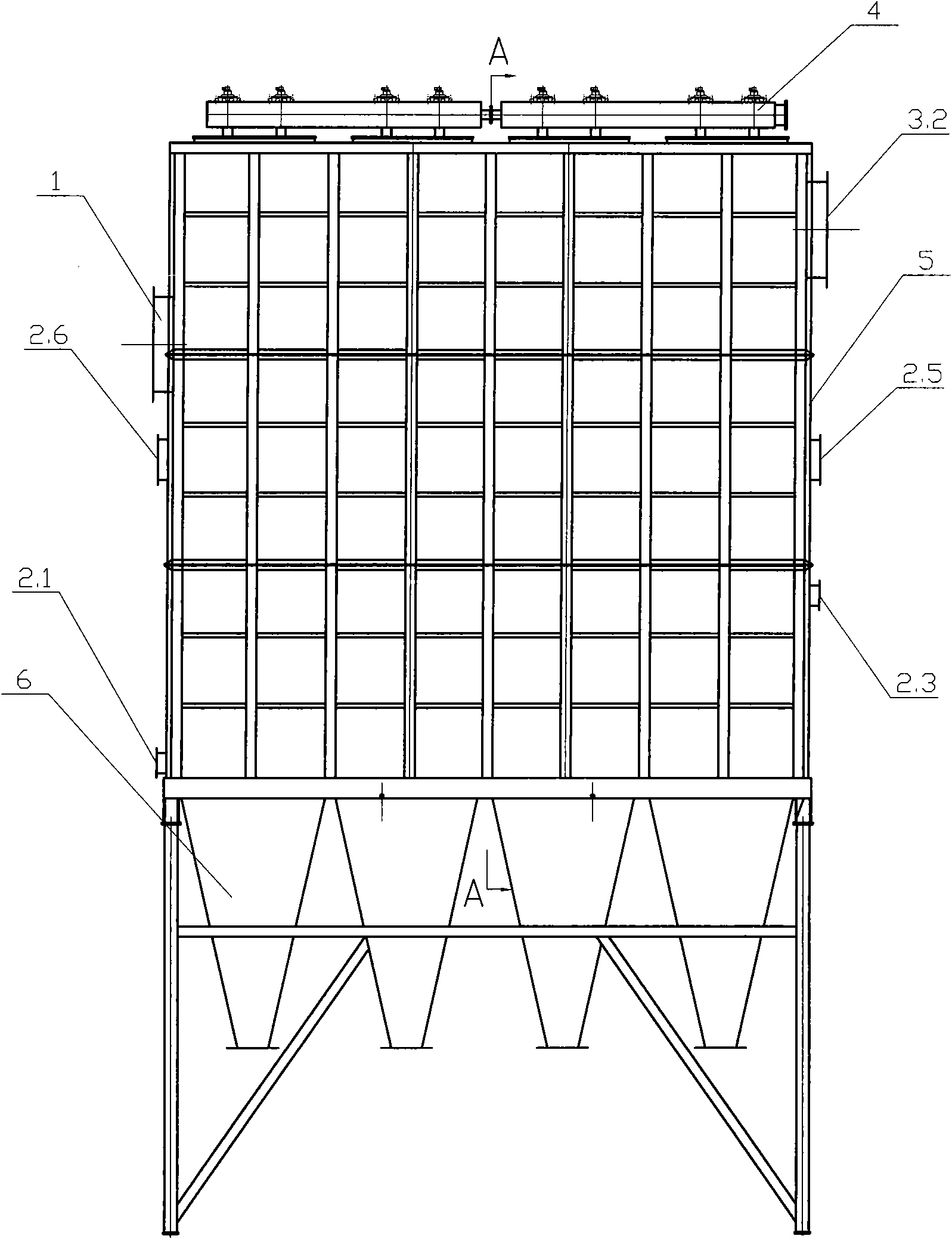

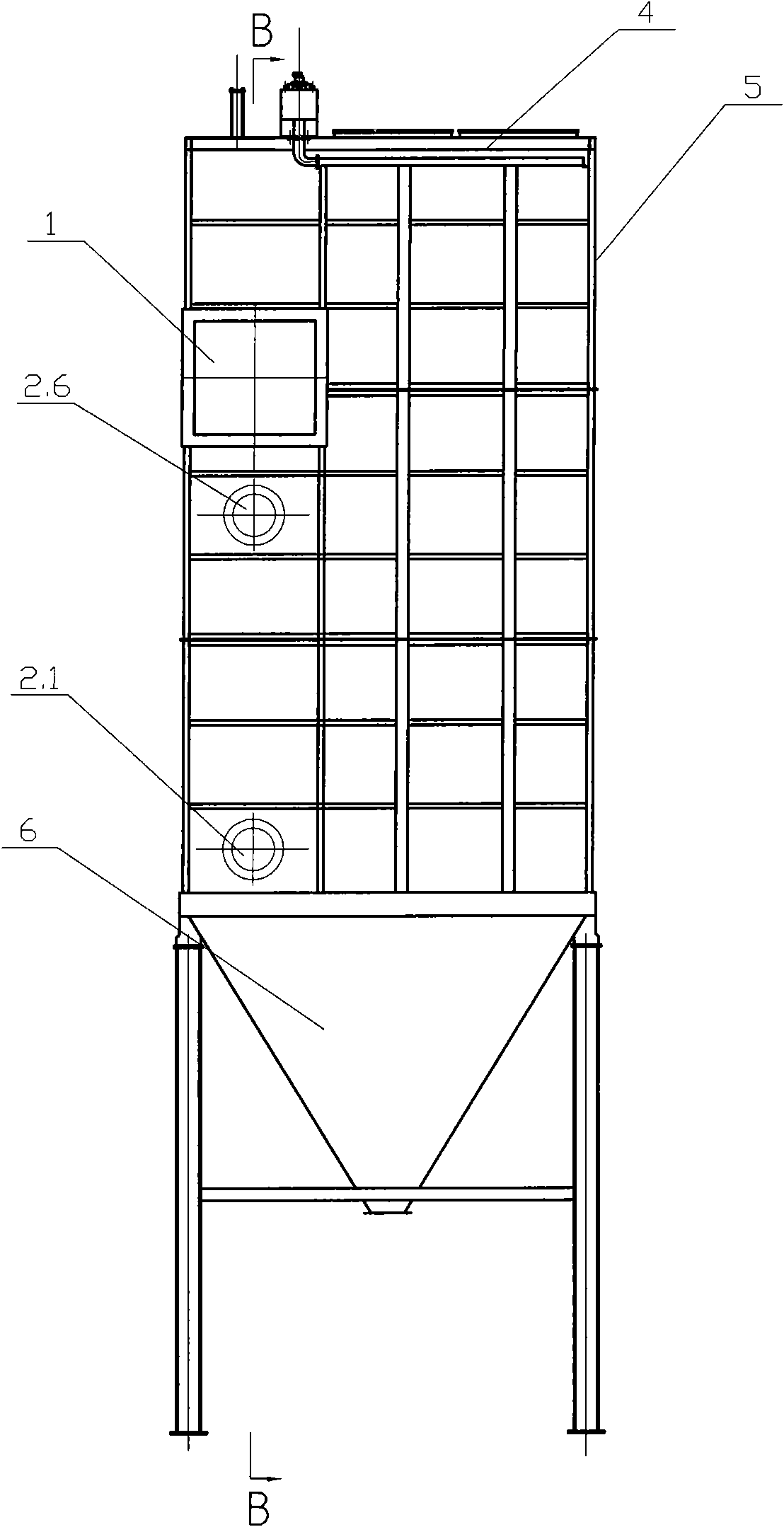

[0017] attached figure 1 The shown integrated arsenic collector includes a rectangular housing 5 with a relatively independent and connected diversion distribution area 1 , a temperature control area 2 , a purification area 3 , a pulse injection assembly 4 and an arsenic collection barrel 6 . The diversion distribution area 1 is in figure 1 The front part of the upper section of the shown housing 5 has a main body that is a recumbent square tube. The left end of the tube is open and the right end is closed. The downward facing tube wall is provided with a set of through holes corresponding to the heat exchange tube 2.2. The arsenic trioxide-containing gas discharged from the front electrostatic precipitator is introduced into the device from the opening at the left end. The temperature control area 2 is located under the diversion dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com