Proton exchange model fuel cell unit, membrane electrode group and gaseous diffusion layer structure

A technology of fuel cell unit and proton exchange membrane, which is applied in the direction of solid electrolyte fuel cells, fuel cells, battery electrodes, etc., and can solve the problems of proton exchange membranes not being available, improving, and overall efficiency deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the present invention can have various changes in different forms without departing from the scope of the present invention, and the The descriptions and diagrams are illustrative in nature and not limiting of the invention.

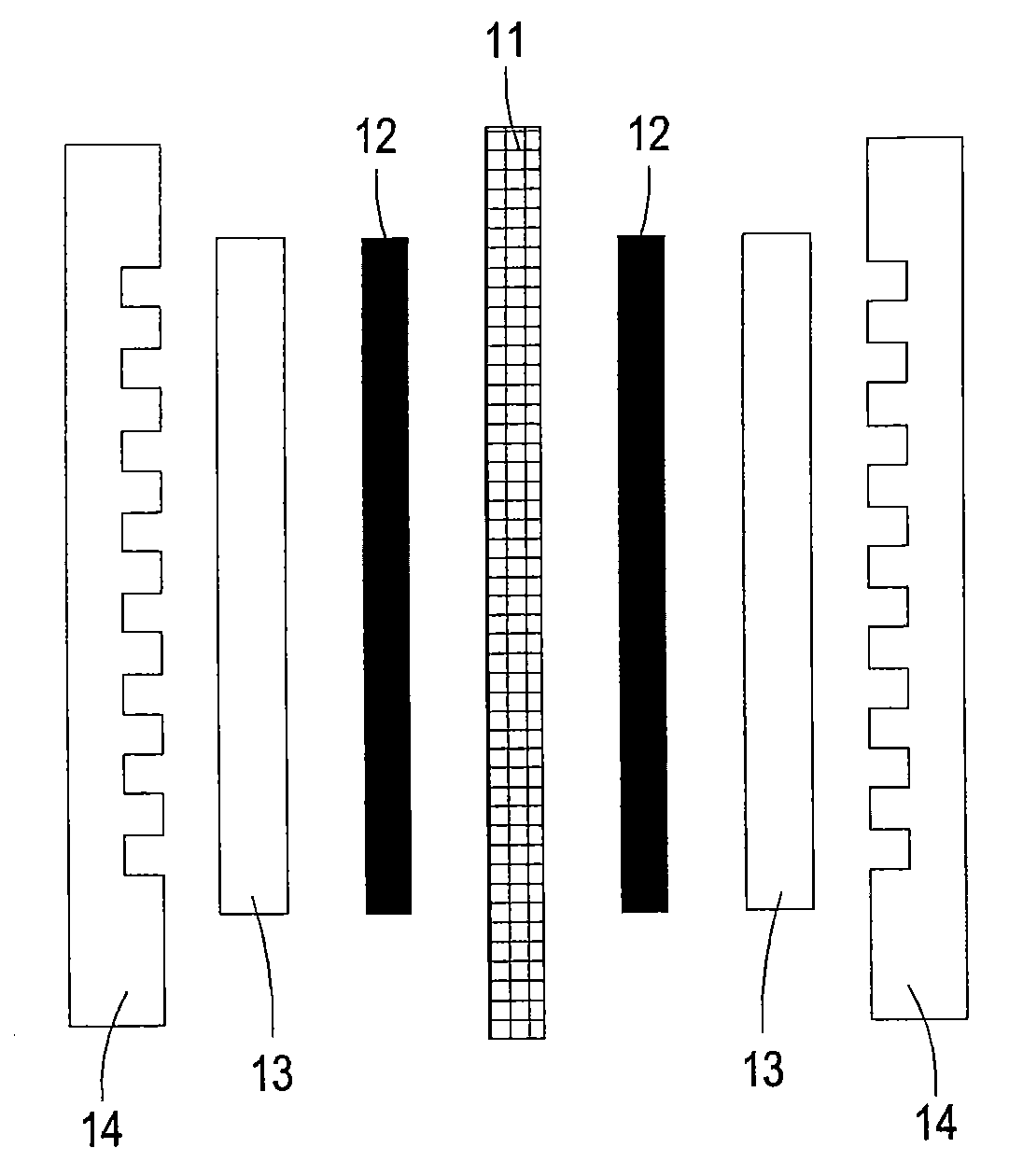

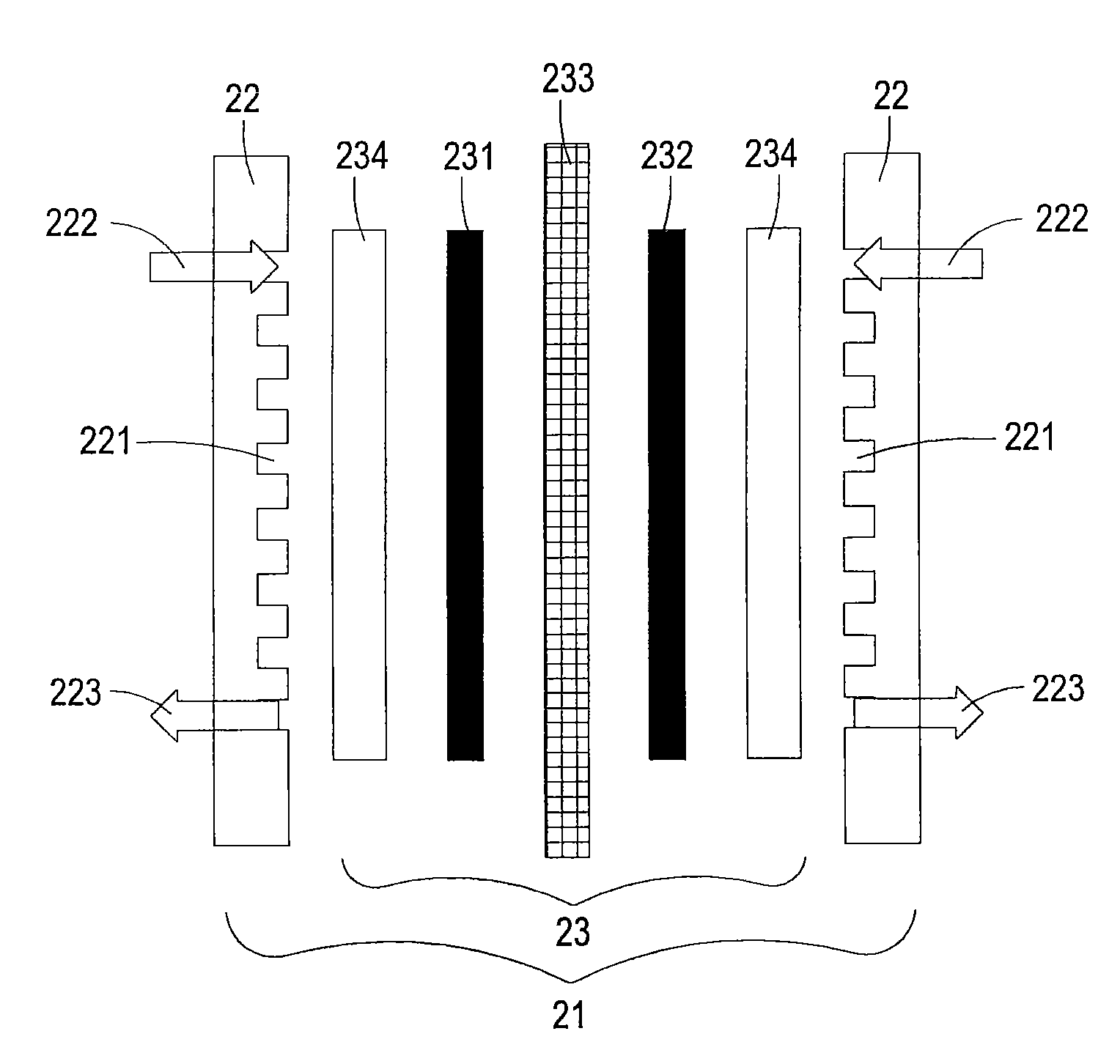

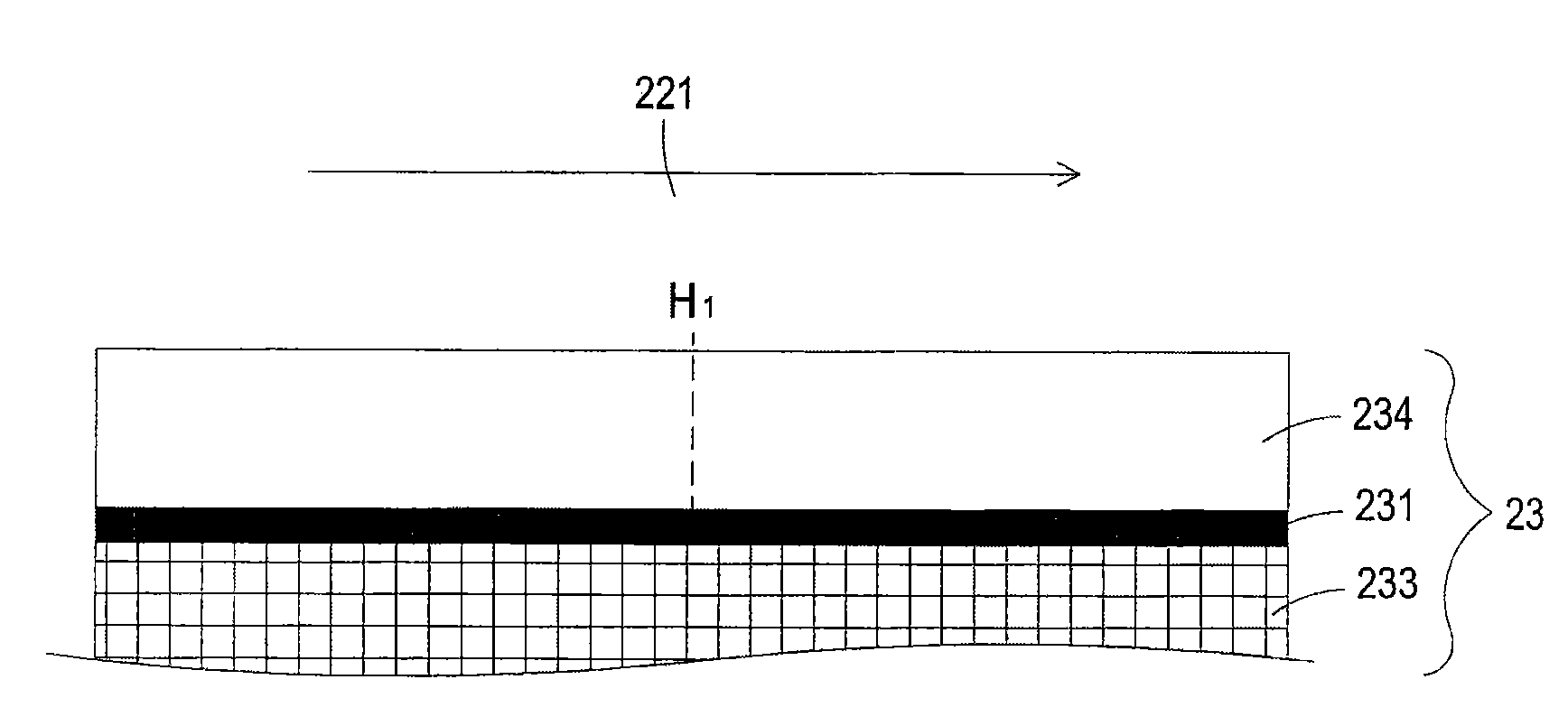

[0048] exist Figure 2A and Figure 2B A proton exchange membrane type fuel cell unit (Fuel cell unit) according to a preferred embodiment of the present invention is described, wherein Figure 2A shows an exploded view of the structure of the fuel cell unit, while Figure 2B A schematic diagram of the relative relationship between the gas diffusion layer and the reaction gas flow channels of the flow field plate in the fuel cell unit is then shown. Figure 2A and Figure 2B The shown proton exchange membrane fuel cell unit converts chemical energy directly into electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com