Step motor controller

A stepping motor and controller technology, applied in the electronic field, can solve problems such as occupying resources of the single-chip microcomputer, increasing the computing burden of the single-chip microcomputer, and running out of control of the stepping motor, so as to achieve the effects of reducing difficulty, smooth rotation, and large driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

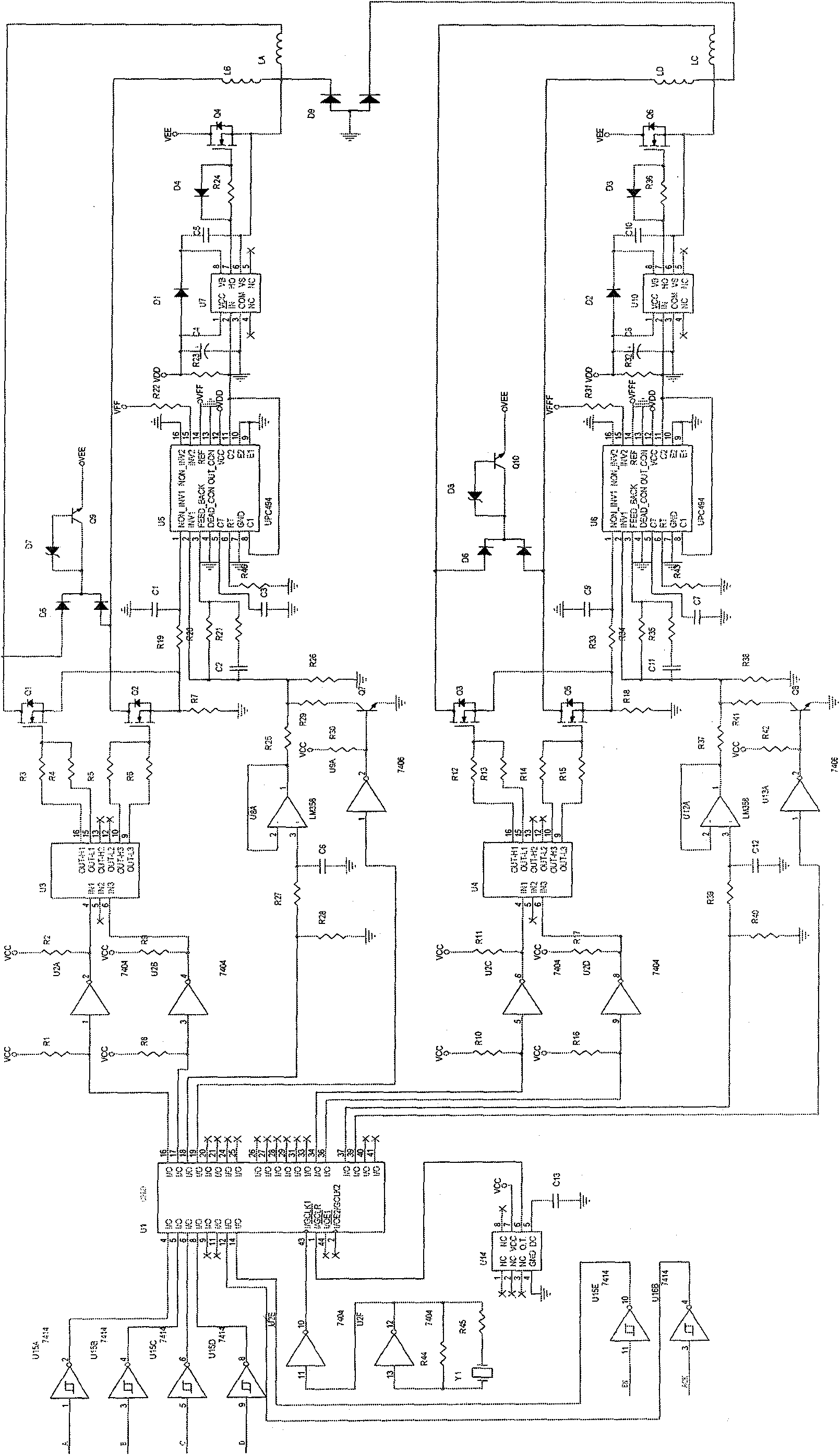

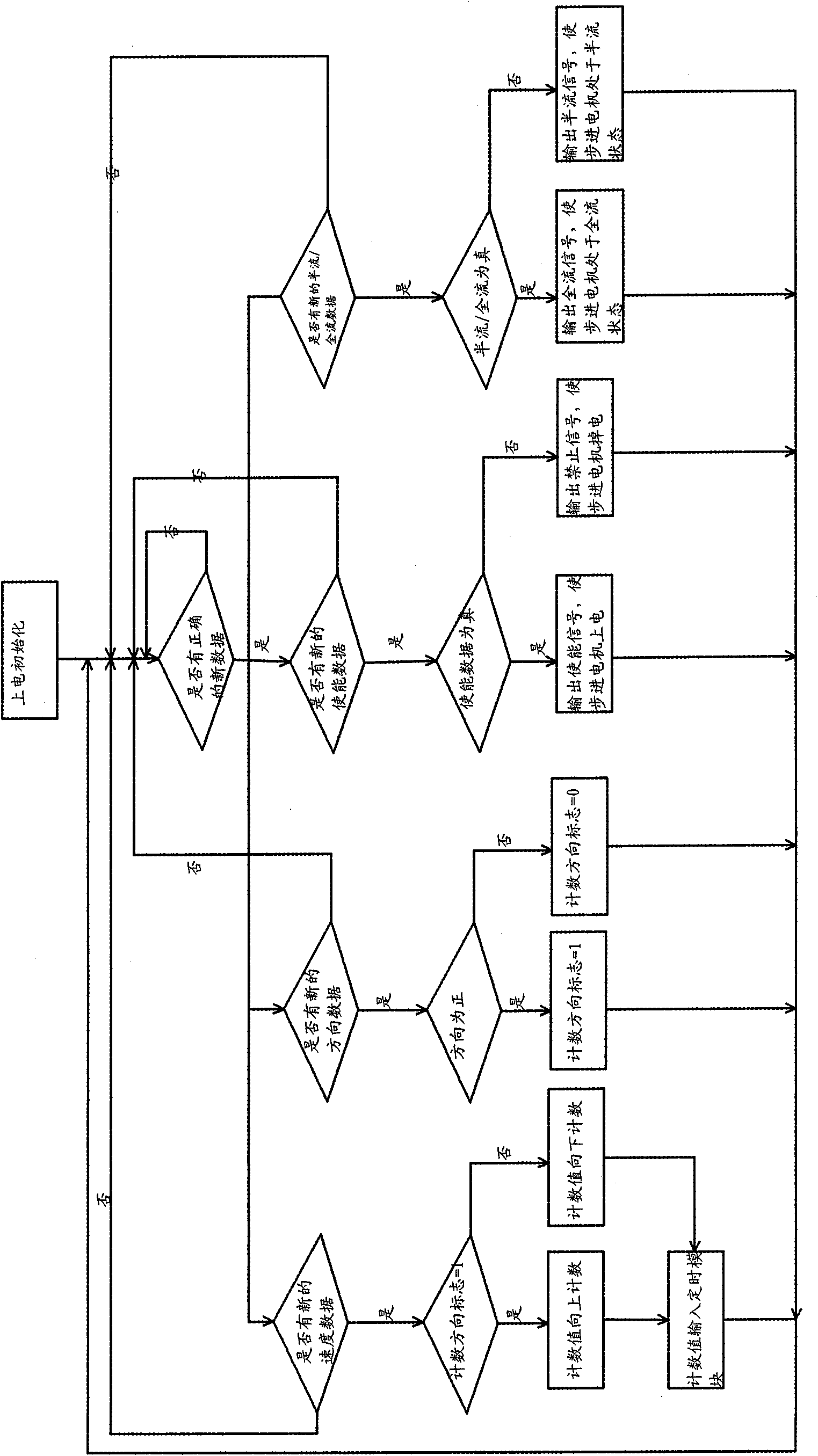

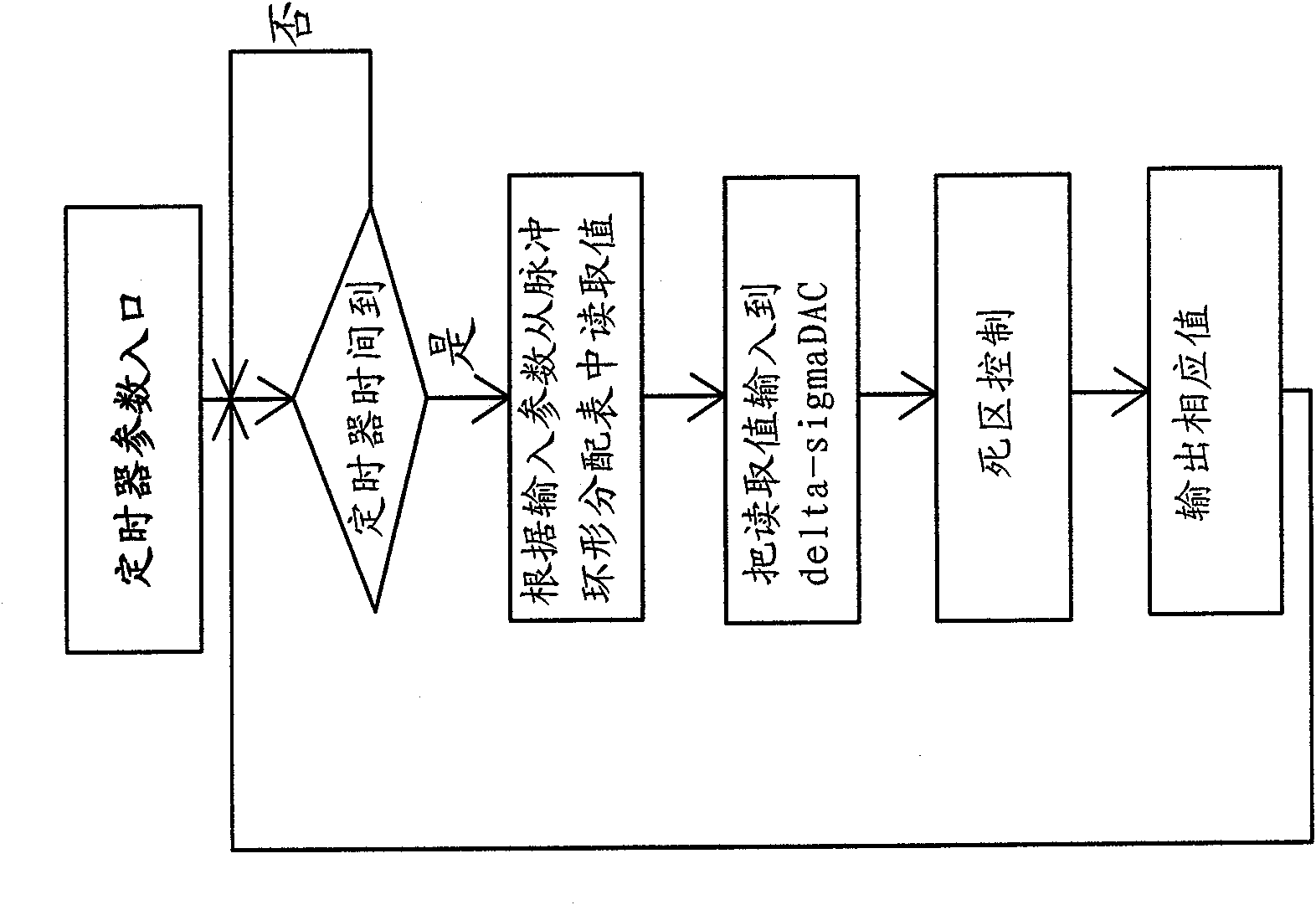

[0021] Such as figure 1 As shown, the stepping motor controller includes a CPLD controller and a driving circuit of a stepping motor connected to it, and counters for counting input pulses corresponding to positive and negative directions are respectively arranged inside the CPLD to provide detailed A timer with a divided time constant, a delta-sigma DAC for realizing the analog output of the I / O port of the CPLD, and a dead zone controller for avoiding circuit short circuit due to the simultaneous opening of the upper and lower bridges in the drive circuit, the described The CPLD signal input terminal is connected with the external single-chip microcomputer, and the output terminal is connected with the driving circuit. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com