Large extruder cylinder inner bore honing device

A kind of honing and large-scale technology, which is applied in the direction of honing machine tools, honing tools, grinding/polishing equipment, etc. It can solve the problems of processing range, specifications, and load-bearing that cannot meet the requirements, and achieve a wide processing range, easy control, and easy honing progress. Give the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be described in detail below in combination with schematic diagrams.

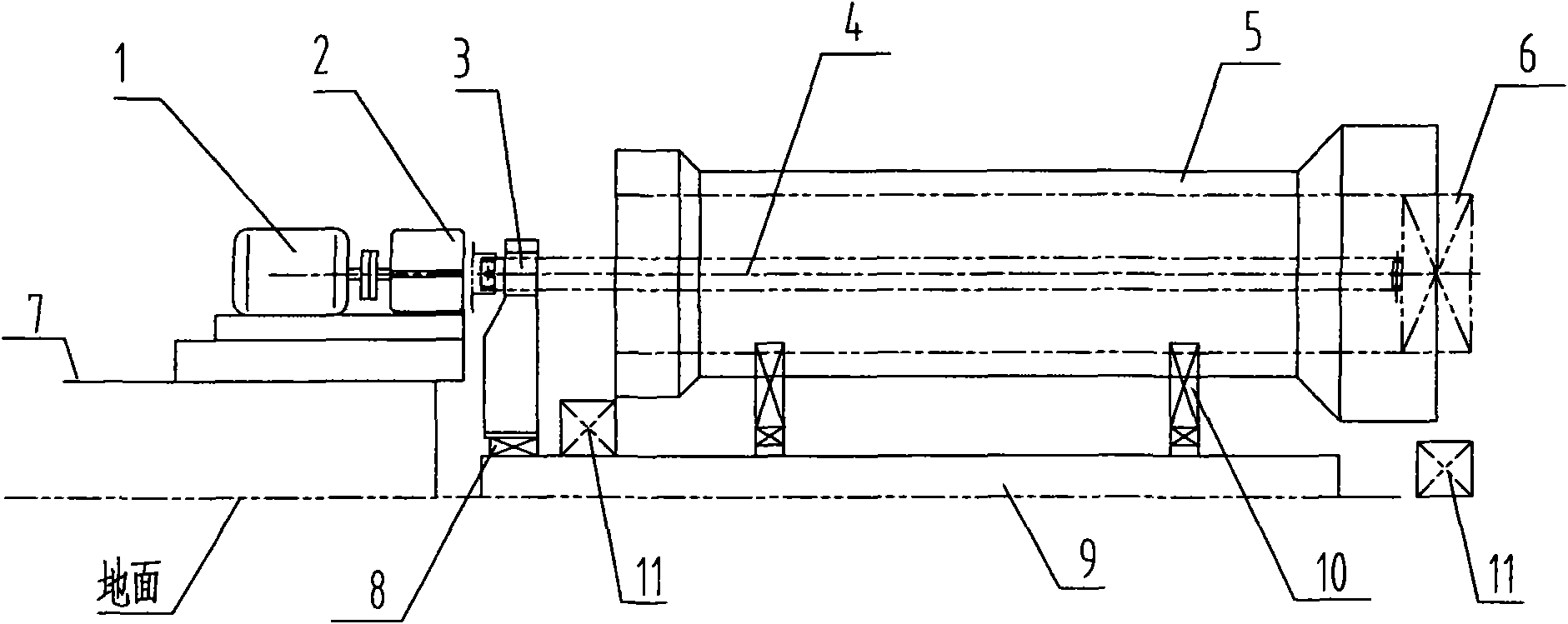

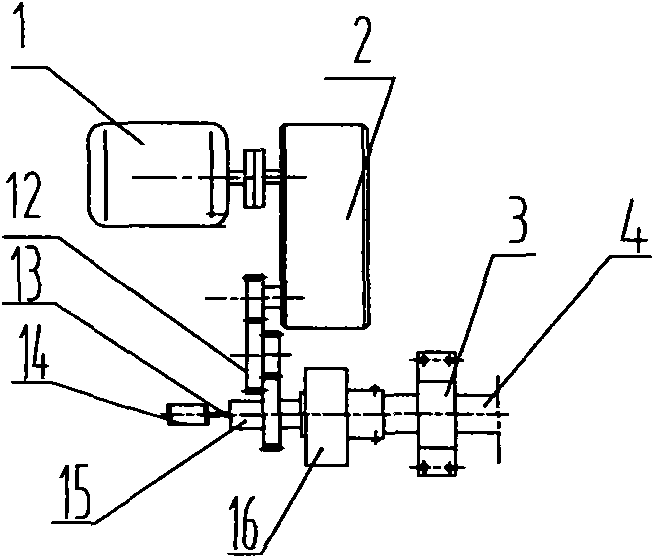

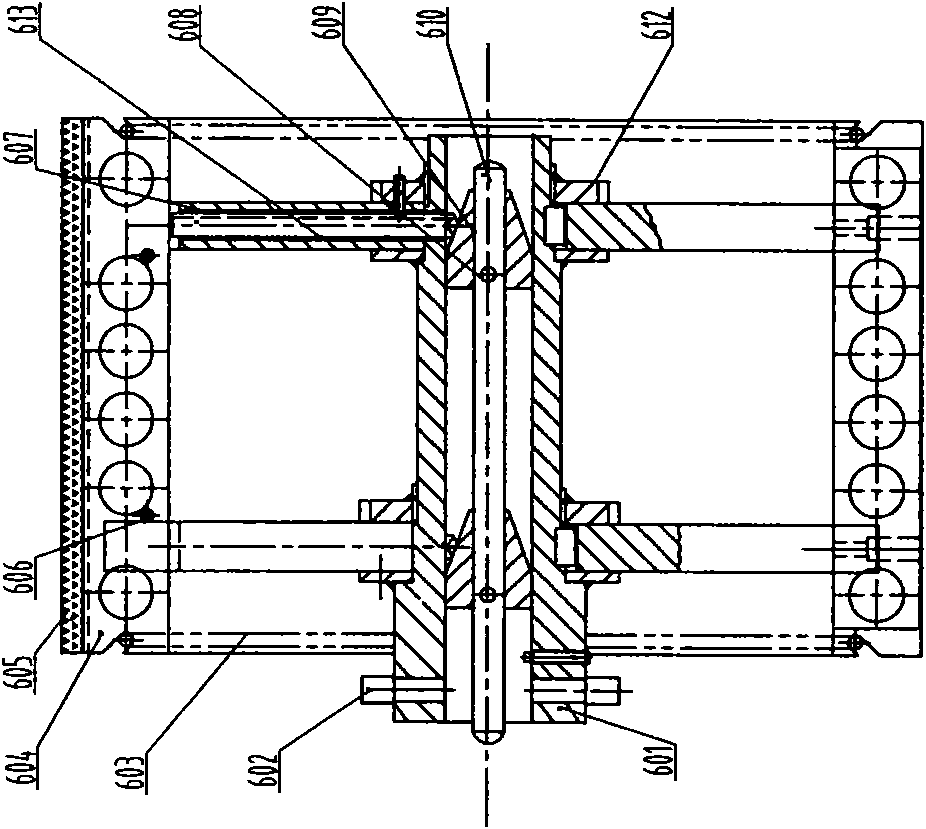

[0018] Such as figure 1 and figure 2 As shown, the honing device for the inner hole of the large extruder cylinder of the present invention. The honing device respectively includes a horizontal motion mechanism with a platform, a rotating mechanism (rotary grinding of the honing head), a feeding mechanism (hydraulic control system) of the honing head oil stone, and a large horizontal ultra-light honing head; it also includes a workpiece platform 9 , adjustable pad iron 8, support seat 3 and V-shaped iron 10; the workpiece platform is placed on the ground of the head of the planer, and the adjustable pad iron, support seat and V-shaped iron are respectively fixed on the workpiece On the platform, two lubricating oil tanks 11 and a lubricating circulation system are arranged at both ends of the workpiece 5 (cylinder body). Wherein said rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com