Method for intermittently producing deuterium depleted water through heavy-oxygen-enriched water separation device and device thereof

A separation device, ultra-light water technology, applied in chemical instruments and methods, heating water/sewage treatment, water, etc., can solve the problem that there is no method and device that can simultaneously obtain heavy oxygen water and ultra-light water with a specific concentration, and no use The problem of isotope separation device for continuous separation of heavy oxygen water and intermittent separation of ultra-light water at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

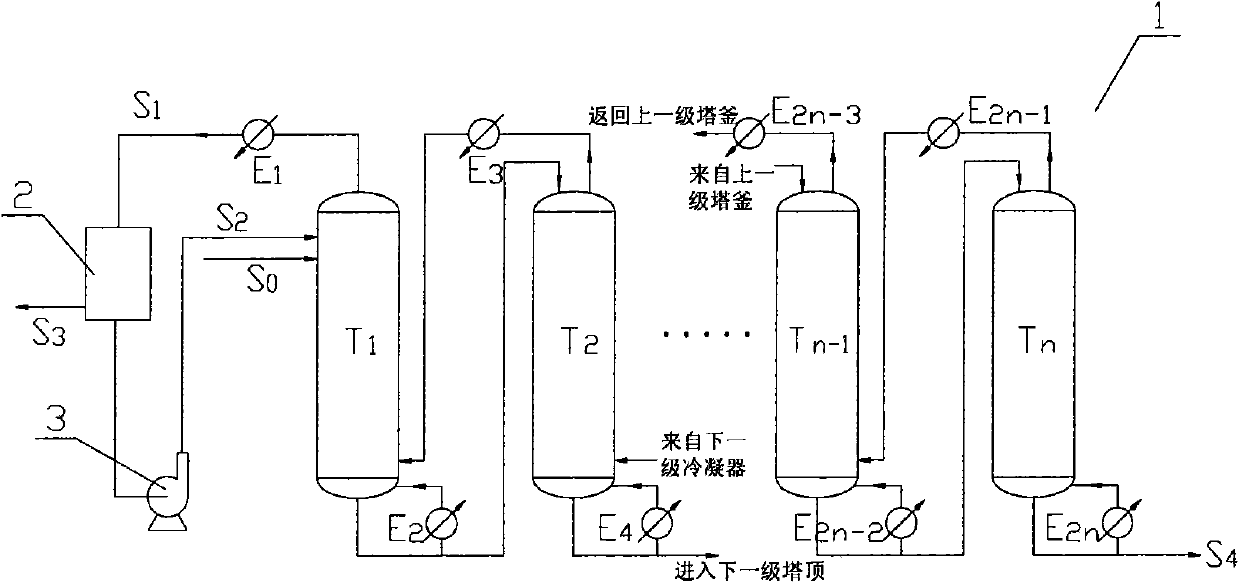

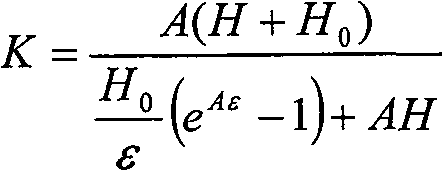

[0092] Using natural water as the raw material, the deuterium abundance is 150ppm, and the flow rate of 250kg / hr enters the first-stage rectification tower. The operating reflux ratio of the first-stage rectification tower is 1, and the theoretical plate number of the heavy oxygen water separation device is 4000 pieces. , A=180±10, the liquid holding capacity of the separation device is 800kg, the operating pressure of the rectification towers at all levels is 120mmHg (absolute pressure), the temperature at the top of the tower is 50°C to 52°C, and the heavy oxygen water product at the bottom of the final rectification tower is collected The output is 5g / hr, and the oxygen-18 abundance is greater than 95% by weight.

[0093] The natural water added in the reflux liquid storage tank makes the total amount of material in the storage tank reach 1000kg, and then simultaneously stops the feeding of the first-stage rectification tower and the extraction at the top of the tower, and p...

Embodiment 2

[0095] Using natural water as the raw material, the deuterium abundance is 150ppm, and enters the first-stage rectification tower from the top of the tower at a flow rate of 250kg / hr. The theoretical plate number of the heavy oxygen water separation device is 4000 pieces, A=180±10, the separation device The liquid holding capacity is 400kg, the operating pressure of the rectification towers at all levels is 70mmHg (absolute pressure), the temperature at the top of the tower is 40℃~42℃, the output of heavy oxygen water product at the bottom of the last rectification tower is 2.8g / hr, and the oxygen- 18 abundance greater than 95%.

[0096] Add natural water into the reflux liquid storage tank to make the material volume in the storage tank reach 300kg, then stop the feeding and top extraction of the first-stage rectification tower at the same time, and change the first-stage rectification tower to total reflux operation , the condensate at the top of the first-stage rectificatio...

Embodiment 3

[0098] Using natural water as raw material, the deuterium abundance is 150ppm, and enters the first-stage rectification tower from the top of the tower at a flow rate of 500kg / hr. The theoretical plate number of the heavy oxygen water separation device is 2500, A=100±5, and the separation device The liquid holdup is 800kg, the operating pressure of the rectification towers at all levels is 120mmHg (absolute pressure), the temperature at the top of the tower is 50°C to 52°C, the output of heavy oxygen water products at the bottom of the final rectification tower is 4.7g / hr, and the oxygen- 18 abundance greater than 98%.

[0099] Add natural water into the reflux liquid storage tank to make the material volume in the storage tank reach 500kg, then stop the feeding and top extraction of the first-stage rectification tower at the same time, and change the first-stage rectification tower to total reflux operation , the condensate at the top of the first-stage rectification tower fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com