Hydraulic power machine

A power machine and hydraulic technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of air, noise pollution, high cost, and failure to become power generation equipment, etc., achieve low repair rate, environmental protection and energy saving purposes, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

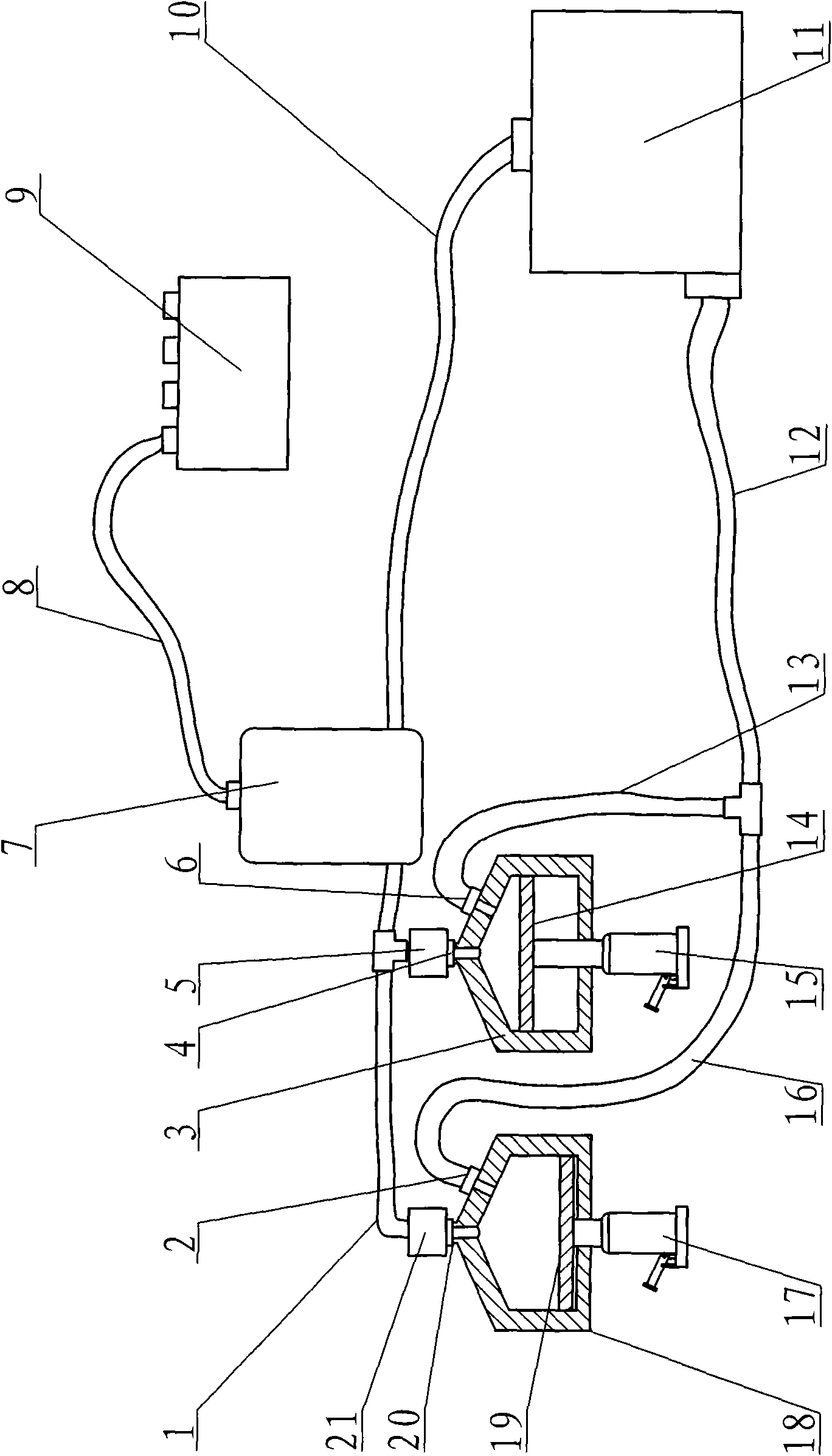

Embodiment 1

[0019] Such as figure 1 As shown, the quantity of the hydraulic cylinder of the present invention is two, and the piston in each hydraulic cylinder is all connected to the driving device, and the driving device is a jack. The jack can be a human jack, which is started by a rocker or a pedal, and is suitable for household or emergency power generation; it can also be a pneumatic jack, which is connected to an air compressor, and the air compressor drives the jack to expand and contract, which is suitable for the power supply needs of large buildings. The jack 17 is connected to the piston 19 of the hydraulic cylinder 18; the upper part of the cylinder barrel of the hydraulic cylinder 18 adopts a tapered design. This design can make the piston 19 difficult to get stuck even if it runs to the upper limit, and the repair rate is low. The output port is set on the top of the cylinder, and the input port is opened on the cone surface. A pressure reducing valve, a flow valve 21 and ...

Embodiment 2

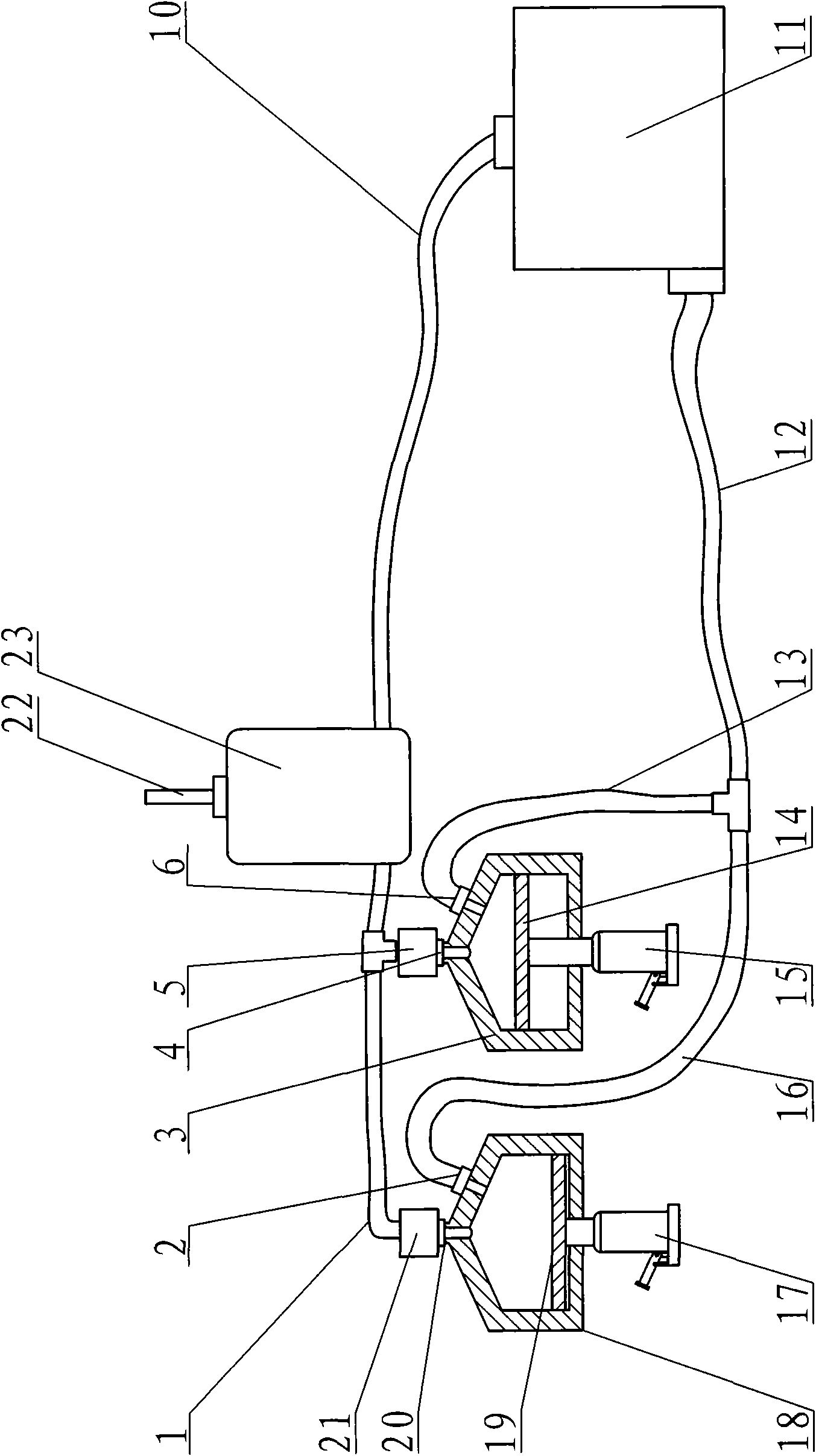

[0024] Such as figure 2 As shown, the impeller generator 7 in Embodiment 1 is replaced by an impeller transmission 23, an impeller is arranged in the impeller transmission 23, and an output shaft 22 is arranged at the center of the impeller, and the rotation of the impeller can drive the output shaft 22 to rotate and output kinetic energy.

[0025] The specific operation process is the same as that of the first embodiment, the impeller of the impeller transmission device 23 is driven by the liquid flow to rotate to generate kinetic energy, which is output through the output shaft 22 . The output shaft 22 can be connected with other devices and converted into various forms of kinetic energy.

[0026] In the present invention, the piston of the hydraulic cylinder is operated alternately up and down by controlling the jack, and the impeller in the impeller generator 7 / impeller transmission device 23 is driven to rotate by transmitting the working fluid through the infusion tube,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com