Temperature measurement method taking carborundum crystals irradiated by neutrons as sensor

A technology of silicon carbide and sensors, which is applied in the field of measurement and testing, can solve the problems that the research results have not been made public, and achieve the effects of simple operation, wide application and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

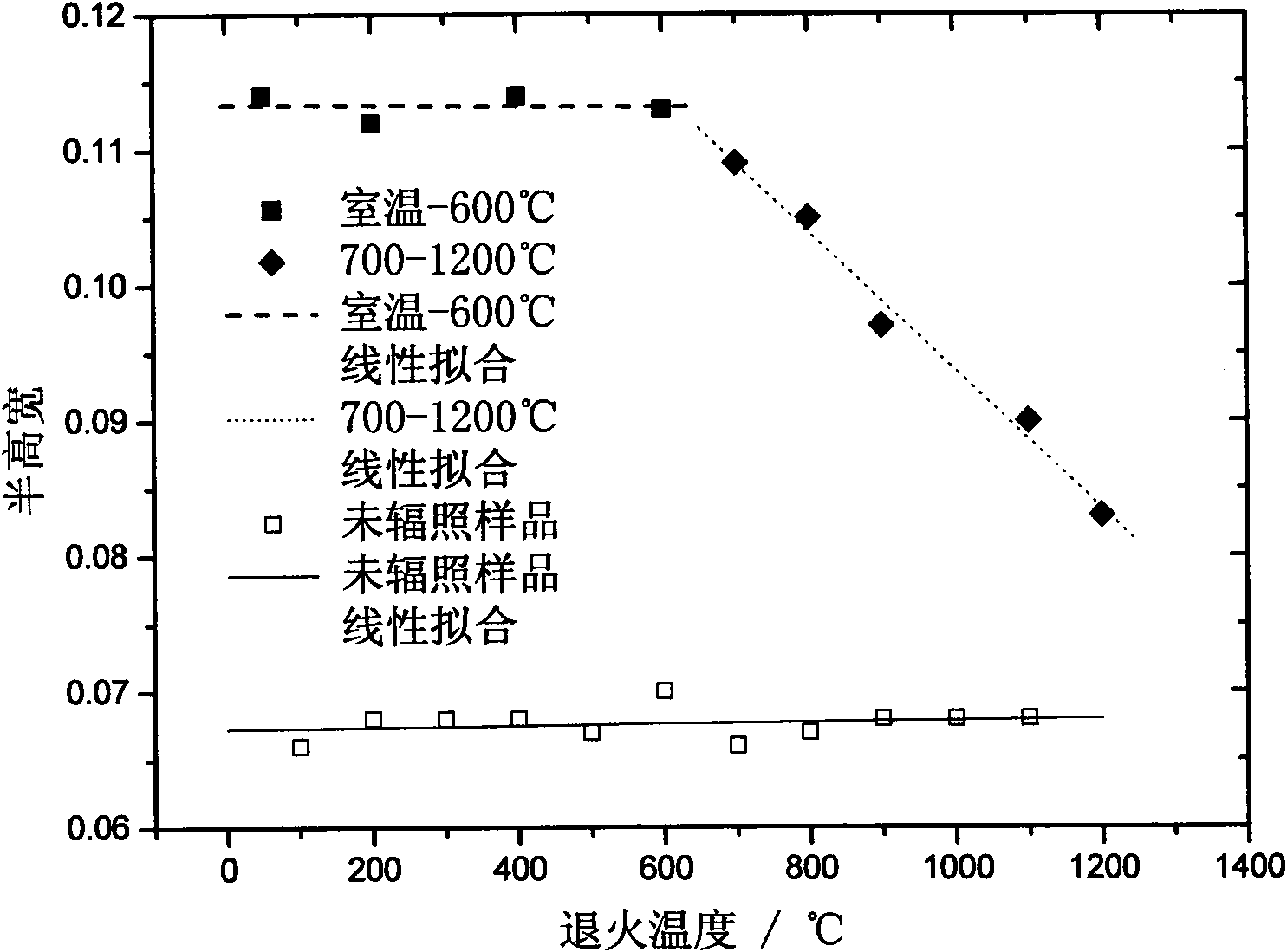

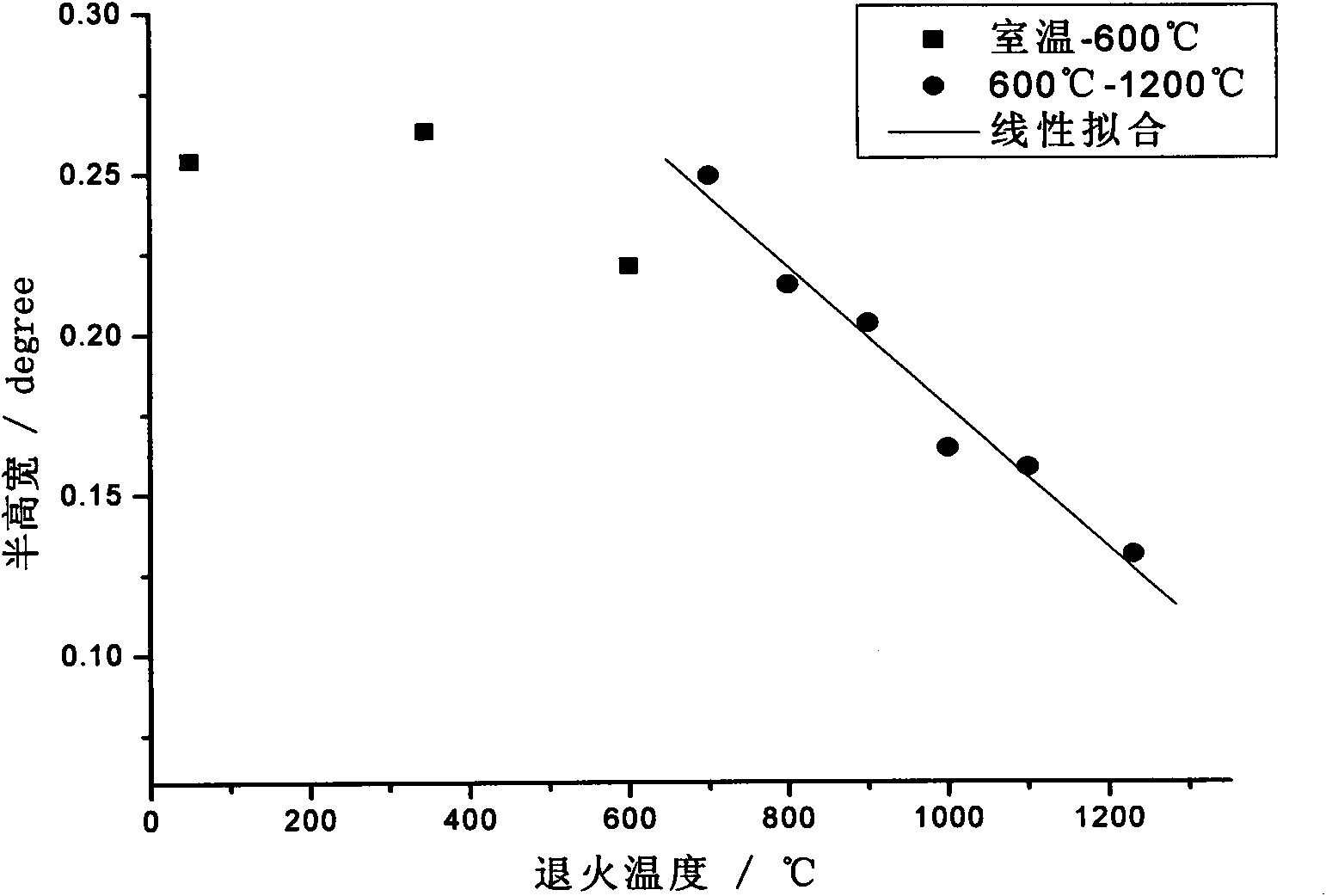

[0041] Example 1: The total flux is 1.72×10 19 / cm 2 F-T curves of thermometric crystals irradiated by neutrons

[0042] Nitrogen-doped 6H-SiC crystals (resistivity at room temperature 2×10 5 Ωcm, light green in appearance) is a temperature measuring crystal, processed into 6×6×0.3mm 3 flakes (see figure 1 ) and irradiated with mixed field neutrons, the neutron flux rate of the irradiation source was 2.3×10 13 cm -2 ·s -1 , where the fast neutron flux rate is 5×10 12 cm -2 ·s -1 , the total flux of irradiation is 1.72×10 19 cm -2 , the temperature in the neutron channel at the time of irradiation is 60-80°C. After irradiation, the sample was annealed isochronously, and a data was made every 100°C and kept for 20 minutes, and the half-height width of the X-ray diffraction peak of the (006) plane of the temperature-measuring crystal was measured respectively, so as to obtain the F-T curve. The half-height width of the X-ray diffraction peak was measured using a Jap...

Embodiment 2

[0043] Example 2: Observation of dislocations in thermometric crystals

[0044] The defects of thermometric crystals (nitrogen-doped 6H-SiC) before and after irradiation or before and after annealing were observed by chemical etching method, using molten KOH and K 2 CO 3 The mixed solution is used as the etchant, and the ratio of the etchant is KOH:K 2 CO 3 =30:0.75 (weight ratio), the etching process is to keep warm at 410°C for 20 minutes. Observing the surface morphology of the etched crystal with optical microscope and SEM, a large number of dislocation pits can be clearly observed on the Si surface. Figure 4 , 5 , 6 are the dislocation topography diagrams of the original sample (non-irradiated and unannealed sample), the irradiated non-annealed sample, and the irradiated sample annealed at 1200°C, respectively, and the magnifications are 200 times. Figure 4 , 5 The results shown in 6 and 6 show that the unirradiated original sample already contains a certain densi...

Embodiment 3

[0045] Embodiment 3: isothermal annealing of thermometric crystal

[0046] Using the sample temperature control system that comes with the Dutch XPERTPRO X-ray diffractometer, the total throughput is 5.74×10 18 / cm 2 The thermometric crystal irradiated by neutrons was isothermally annealed, and the full width at half maximum of the X-ray diffraction peak of the (006) plane of the sample was measured and recorded "on-line" (instantly). Measurements were made at 8 time points within 2 hours, and the measurement time intervals ranged from 5 minutes to 1 hour. The obtained 8 XRD lines were all recorded in Figure 7 among. exist Figure 7 Among them, 8 XRD lines are highly overlapped, indicating that the full width at half maximum (reflecting the dislocation density) of the X-ray diffraction peak of the thermometric crystal is only related to the annealing temperature, but not to the annealing time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com