Color solidification property composition

A curable composition and compound technology, applied in nonlinear optics, chemical instruments and methods, porphine/acridine porphine, etc., can solve the problem of low brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0227] The present invention is further specifically described below by way of examples.

Synthetic example 1

[0229]

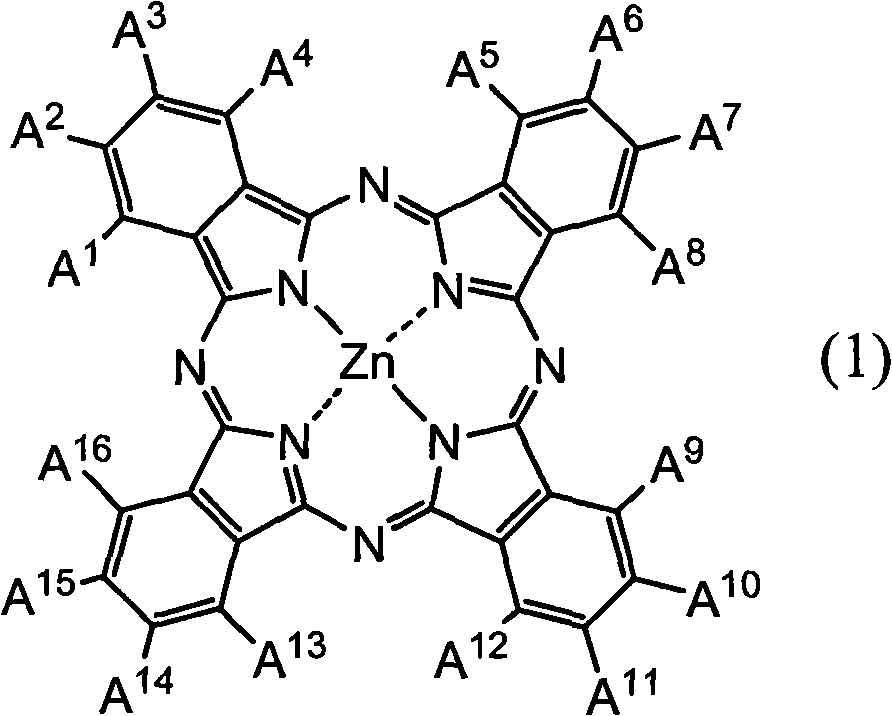

[0230] In a 1000mL four-neck flask, add tetrachlorophthalonitrile 106.4g (400 mmol), zinc chloride 14.3g (105 mmol), urea 84.0g (3000 mmol), ammonium molybdate tetrahydrate 19.9 g (30 mmol) and 100 mL of methylnaphthalene were heated at 200° C. for 6 hours under a nitrogen atmosphere. The precipitate was taken out by filtration, washed with methanol and then with warm water at 60°C, and then dried under reduced pressure at 60°C to obtain 29.7 g of zinc hexadecylchlorophthalocyanine.

[0231]Next, in a 500mL four-necked flask, 90.7g (680mmol) of anhydrous aluminum chloride and 11.7g (200mmol) of sodium chloride were mixed at 40°C, and 25.0g (22mmol) of hexadecylchlorophthalocyanine zinc was added. mol) stirred, then 60.0 g (751 mmol) of bromine was dripped, heated to 130°C over 20 hours, and kept for 1 hour. The obtained reactant was taken out and put into water, and the crude pigment of chlorinated brominated phthalocyanine was precipitated. The crude chlorinated ...

Synthetic example 2

[0235]

[0236] In a 1000mL four-necked flask, add sulfuryl chloride 89.1g (660 mmol), anhydrous aluminum chloride 90.7g (680 mmol), sodium chloride 12.3g (210 mmol), and mix at 40°C , 25.0 g (43.3 mmol) of zinc phthalocyanine was added and stirred, then 60.0 g (751 mmol) of bromine was added dropwise with stirring, and the temperature was raised to 130° C. over 20 hours and kept for 1 hour. The obtained reactant was taken out and put into water, and the crude pigment of chlorinated brominated phthalocyanine was precipitated. The crude chlorinated brominated phthalocyanine pigment slurry was filtered, washed with warm water at 60°C, washed with 1% aqueous sodium bisulfate solution, washed with warm water at 60°C, and dried under reduced pressure at 60°C to obtain 22.5 g of refined chlorinated brominated phthalocyanine crude pigments.

[0237] Next, 20 g of the chlorinated brominated phthalocyanine crude pigment obtained by the above operation, 60 g of sodium chloride and 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com