Process for producing enclosed halogen tungsten automobile headlight

A technology for automobile headlights and production processes, which is applied to electrical components and other directions, can solve the problems of unstable quality of artificially bent molybdenum feet, low work efficiency, poor spot welding performance, etc. Improved and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

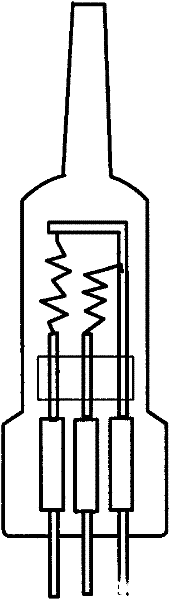

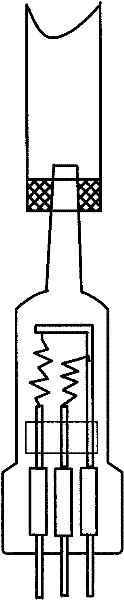

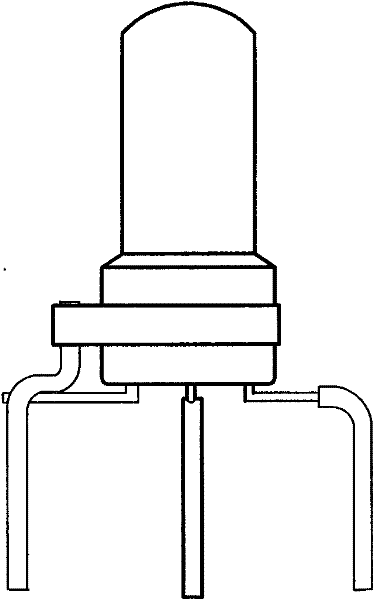

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] refer to Figure 4 , a kind of closed-type tungsten-halogen automotive headlight production process, the production process comprises the following steps:

[0031] (1) Mounting: welding the filament to the lamp holder;

[0032] (2) Butt welding: the copper and molybdenum feet are melted and joined together through the two ends of the electrification to form copper and molybdenum feet:

[0033] (3) Spot welding molybdenum sheets: one end of the three molybdenum sheets is spot-welded with the three molybdenum rods on the lamp stand, and the other end of the three molybdenum sheets is spot-welded with three copper-molybdenum feet respectively;

[0034] (4) After the wick and glass bulb are made, press seal, and keep the exhaust rod at the upper end of the glass bulb: press seal the wick in the glass bulb, wherein the copper-molybdenum feet protrude from the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com