Directly-driven wind power generation system and mode for modulating SPWM inversion control signal in system

A wind power generation system, direct drive technology, applied in electrical components, output power conversion devices, AC power input conversion to DC power output, etc. System cost and other issues, to achieve the effect of simplifying design and control, reducing cost and saving capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

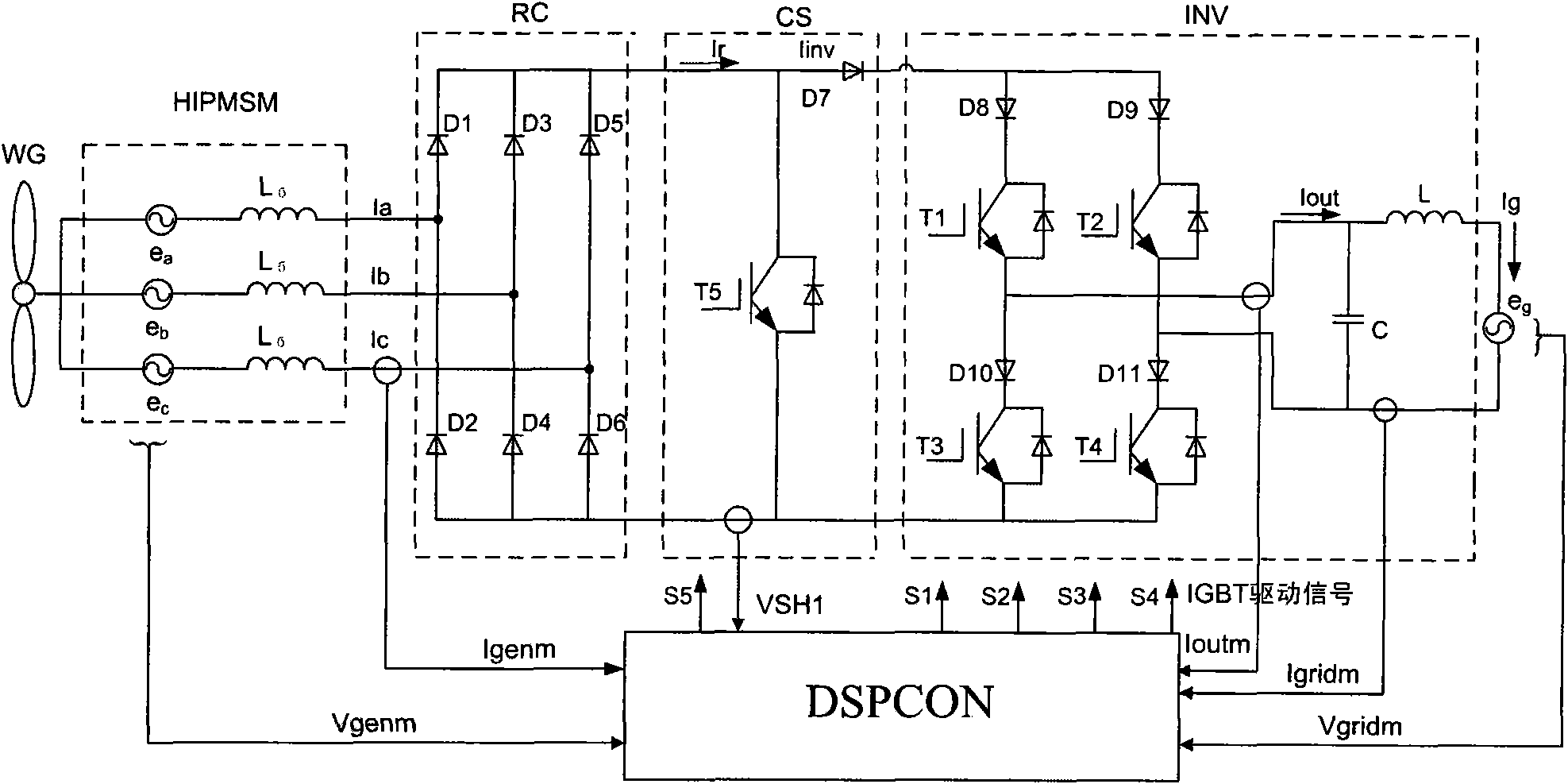

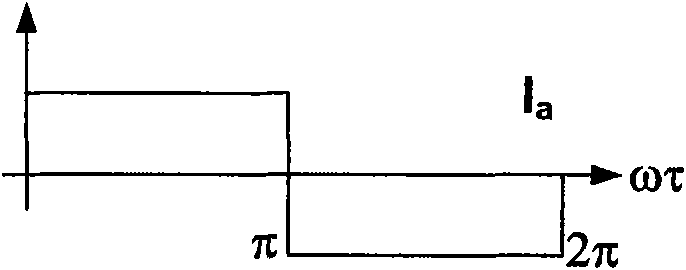

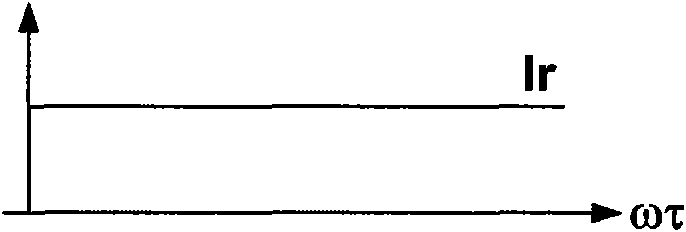

[0031] figure 1 As shown, a high-inductance permanent magnet synchronous generator is coaxially connected with the wind turbine to form a direct-drive wind power generation system. When the wind speed reaches the cut-in wind speed of the system, the high-inductance permanent magnet generator, driven by the wind turbine, outputs an AC current that approximates a rectangular wave, as shown in Figure 2(a). The output of the high-inductance permanent magnet generator is connected in series with a three-phase uncontrolled rectifier composed of power diodes D1-D6. The three-phase uncontrollable rectifier rectifies the AC current output by the high-inductance permanent magnet generator to obtain a DC current source with a basically constant amplitude, and its amplitude basically does not change with the wind speed, as shown in Figure 2(b). Show.

[0032] A power electronic switch T5 connected in parallel with the output of the rectifier circuit and a fast diode D7 form a current shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com