Method for manufacturing low-polymerization-degree full resin coated grinding tool

A technology of coated abrasives with a low degree of polymerization, which is applied in the manufacture of tools, abrasives, and metal processing equipment. It can solve problems such as product brittleness, quality differences between the inside and outside of large rolls of coated abrasives, and color differences in appearance. The effect of uniform quality, guarantee of consistency and uniformity, and improvement of product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

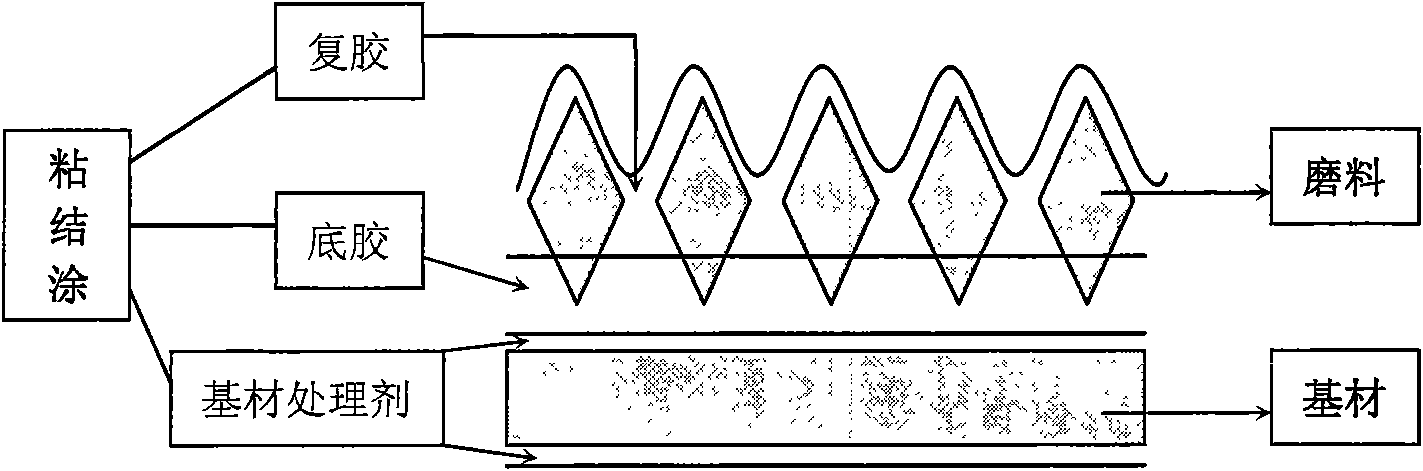

[0019] Such as figure 1 The coated abrasive product shown has two layers of coating, a primer layer and a size coat. The primer layer is coated on one side surface of the base material, the abrasive is adhered to the primer layer, and the compound glue layer is coated on the abrasive material.

[0020] In fact, in order to make the coated abrasive product work better, it is often necessary to apply a supercoat on the size layer. For grinding wood, rubber, plastic, leather and other objects that are prone to static electricity in a dry environment, the super coating can prevent the accumulation of static electricity, prevent the explosion caused by dust in the environment, and prevent the abrasive debris from adhering to the back of the abrasive belt, etc. ; When grinding soft non-ferrous metals such as copper and aluminum, the super coating can prevent grinding debris from attaching to the surface of the abrasive belt, preventing slipping and clogging, etc.; when grinding sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com