High-performance TPV composite material

A composite material, high-performance technology, applied in the field of high-performance TPV composite materials, can solve the problems of heat resistance, poor high temperature water resistance, poor thermal stability, easy softening and relaxation, etc., to improve weather resistance and heat resistance, improve stability, Improve the effect of surface grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

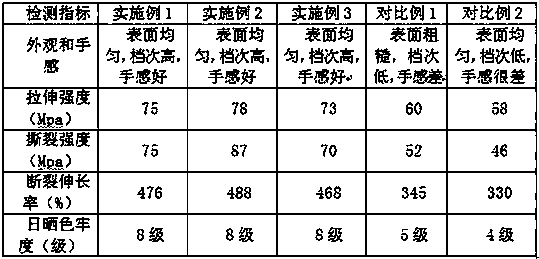

Examples

preparation example Construction

[0025] The preparation method of high-performance TPV composite material of the present invention specifically comprises the following steps:

[0026] 1) Put the components of the above-mentioned modified TPV material into the hopper according to their ratio;

[0027] 2) Adjust the position of the inner die opening and the outer die opening of the extruder die head to avoid eccentricity of the TPV composite wire;

[0028] 3) Set the temperature of each section of the screw extruder to be controlled at 180°C in the feed section, 190°C in the compression section, and 200°C in the homogenization section. The temperature of the die head is set at 210°C. Through the inner and outer die openings of the die head, the modified TPV material enters the screw extruder, and the pellets are driven by the screw extruder to move toward the head. After three-stage heating, the temperature of the pellets at the outlet of the die head reaches 200 ℃, enter the extruder die head in a molten stat...

Embodiment 1

[0032] 1) TPV composite material weight ratio: 85% modified TPV material, 15% silk or cotton thread;

[0033] 2) The silk thread is glass fiber with specification 1000D;

[0034] 3) The modified TPV material includes the following components by weight: 80 parts by weight of TPV elastomer, 30 parts by weight of plasticizer, 15 parts by weight of filler, 12 parts by weight of flame retardant, 3 parts by weight of lubricant, The antioxidant of 3 weight parts and the light stabilizer of 3 weight parts; Wherein, TPV elastomer selects PP / ACM for use; Plasticizer is TCP; Lubricant is polyethylene wax; Antioxidant is antioxidant 168; The agent is UV-531; the filler is talcum powder; the flame retardant is ammonium polyphosphate and magnesium hydroxide, the ratio is 1:1.

Embodiment 2

[0036] 1) TPV composite material weight ratio: modified TPV material 75%, silk thread or cotton thread 25%;

[0037] 2) The thread is 300D polyester industrial filament;

[0038] 3) The modified TPV material includes the following components by weight: 67.5 parts by weight of TPV elastomer, 20 parts by weight of plasticizer, 10 parts by weight of filler, 7.5 parts by weight of flame retardant, 1.6 parts by weight of lubricant, The antioxidant of 1.6 parts by weight and the light stabilizer of 1.6 parts by weight; Wherein, TPV elastomer selects PP / PE / EPDM for use; Plasticizer is DOTP; Lubricant is stearic acid and polyethylene wax, ratio 4:3; The antioxidant is antioxidant 1010; the light stabilizer is UV-531; the filler is two kinds of barium sulfate and calcium carbonate, the ratio is 1:1; the flame retardant is decabromodiphenylethane and antimony trioxide, the ratio is 1 :1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com