Vertical takeoff and landing aircraft

A vertical take-off and landing aircraft and vertical tail technology, applied in the field of aircraft, can solve the problems of increasing engine power, large rotor diameter, large fuel consumption, etc., and achieve the effect of increasing power, improving use efficiency, and simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

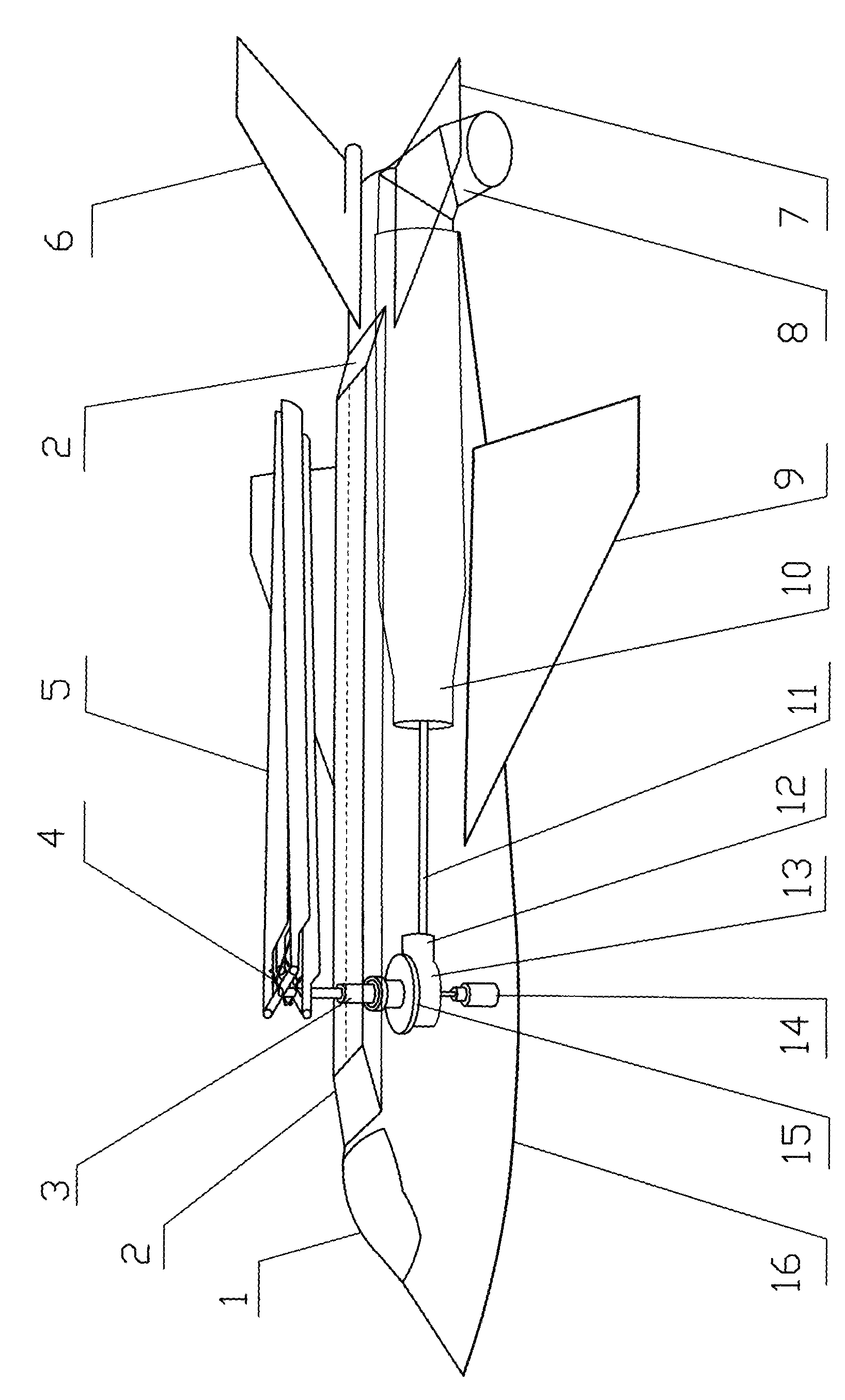

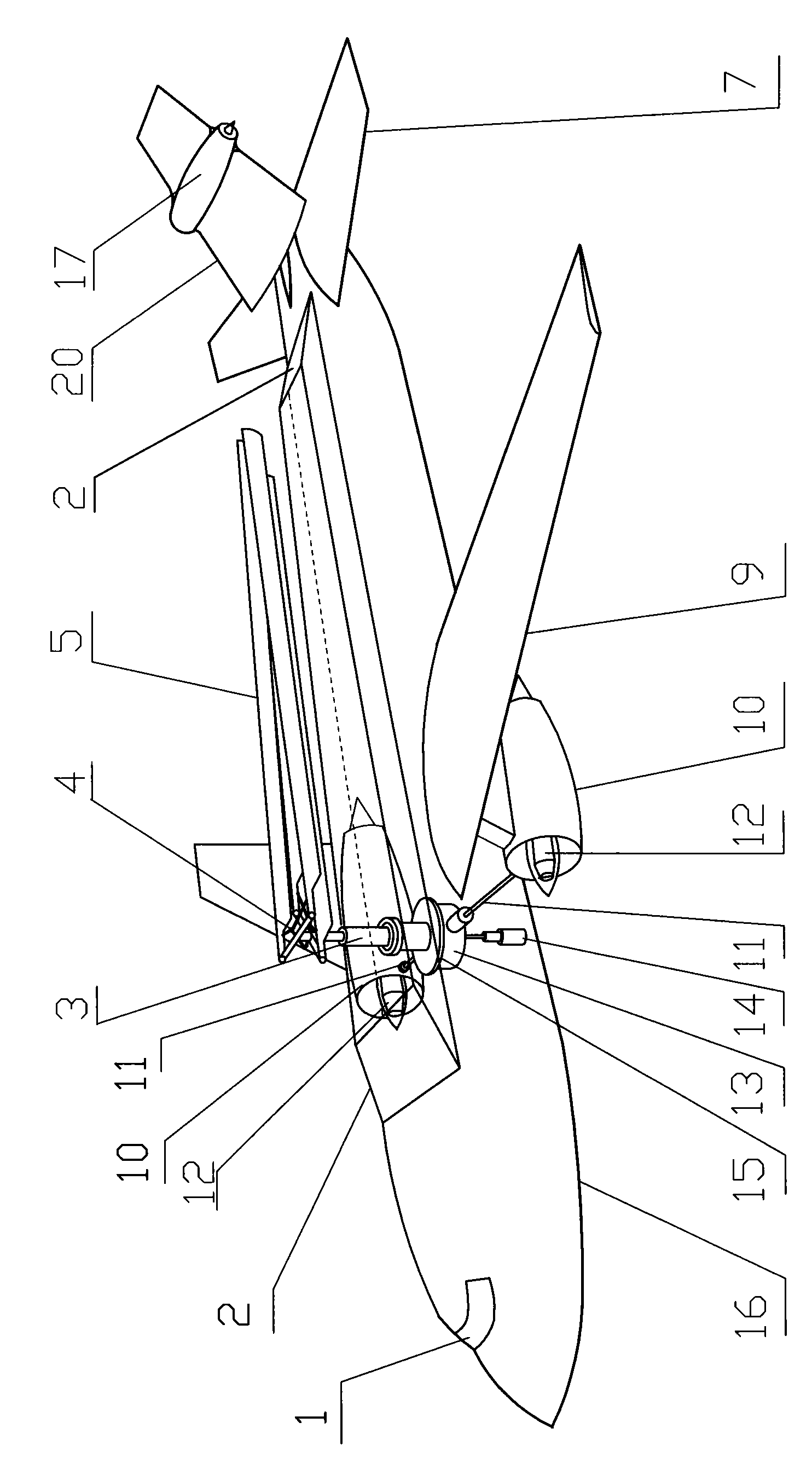

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] exist figure 1 Among them, the vertical take-off and landing aircraft is made of cockpit 1, fuselage 16, aeroengine 10, wing 9, horizontal tail 7, vertical tail 6 and control system, and rotor 5 is equipped with on the fuselage 16 top, and rotor 5 is equipped with rotor automatic Positioning device 4, rotor 5 is connected with rotor shaft 3, rotor shaft 3 is connected with speed reducer 13, rotor shaft telescopic device 14, rotor shaft automatic positioning device 15 is housed on rotor shaft 3, the rotor that can open and close is equipped with on the top of fuselage 16 Cabin 2, aeroengine 10 is connected with speed reducer 13 through transmission shaft 11, clutch 12, and aeroengine 10 rear portion is equipped with steering vector tail nozzle 8. The profile design of aircraft is basically similar to common aircraft design, and the rotor compartment 2 that can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com