Purificant used for desulfuration of propylene and ethylene light hydrocarbon materials and preparation method thereof

A purification agent and ethylene technology, applied in chemical instruments and methods, organic chemistry, other chemical processes, etc., can solve the problems of small arsenic capacity, large bulk ratio, and small porosity, and achieve high arsenic removal accuracy and large arsenic capacity , the effect of strong desulfurization function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a purifying agent for dearsenic removal of propylene and ethylene light hydrocarbon materials is:

[0023] Add water to 390-400Kg of copper nitrate to 1000L to make an aqueous solution of copper nitrate for later use;

[0024] Add 500-510kg of zinc nitrate to 1000L with water to make an aqueous solution of zinc nitrate for later use;

[0025] Add water to 900-910Kg aluminum nitrate to 1000L to make aluminum nitrate aqueous solution for later use;

[0026] Sodium carbonate, sodium hydroxide or sodium bicarbonate formulated as Na 2 O content is the aqueous solution of 6-12% standby;

[0027] Add the above-prepared sodium carbonate, sodium hydroxide or sodium bicarbonate solution into the reaction kettle first, and then add the prepared copper nitrate, zinc nitrate and aluminum nitrate solutions into the reaction kettle in parallel to the alkaline solution in the reaction kettle. Co-precipitation reaction in the solution under the heating conditi...

Embodiment 2

[0029] A preparation method of a purifying agent for dearsenic removal of propylene and ethylene light hydrocarbon materials is:

[0030] 394g of copper nitrate, 504g of zinc nitrate, and 896g of aluminum nitrate were prepared into 1000ml aqueous solution respectively, 1000g of sodium carbonate was prepared into 1000ml of solution, the sodium carbonate solution was put into the reactor, heated to 60°C under stirring, copper nitrate, Zinc nitrate and aluminum nitrate solutions flow into the sodium carbonate solution concurrently, the flow rate is 50ml / hr (i.e. the pH value at the contact point is 7.5), coprecipitated for 1.5 hours, then filtered, washed and dried at 100°C for 24 hours, then Roast at 350°C for 4 hours and extrude into strips of ∮1.5X3-5mm to obtain the finished product.

Embodiment 3

[0032] A preparation method of a purifying agent for dearsenic removal of propylene and ethylene light hydrocarbon materials is:

[0033] Copper sulfate and zinc sulfate were formulated into aqueous solutions containing 13% CuO and ZnO, and aluminum nitrate was formulated into Al 2 o 3 For an aqueous solution with a content of 10%, put 1000ml of 1:6 ammonia water into the reactor, heat it to 30°C in a closed stirring state, and add copper nitrate, zinc nitrate and aluminum nitrate solutions into the ammonia solution in parallel to ensure that the liquid flow The pH value at the contact point is 7.5. When the pH value of the entire solution in the kettle is 7.5, the co-precipitation is over, and then filtered and washed, dried at 100°C for 24 hours, and then roasted at 380°C for 4 hours and extruded into ∮1.5 X3-5mm strip, that is, the finished product.

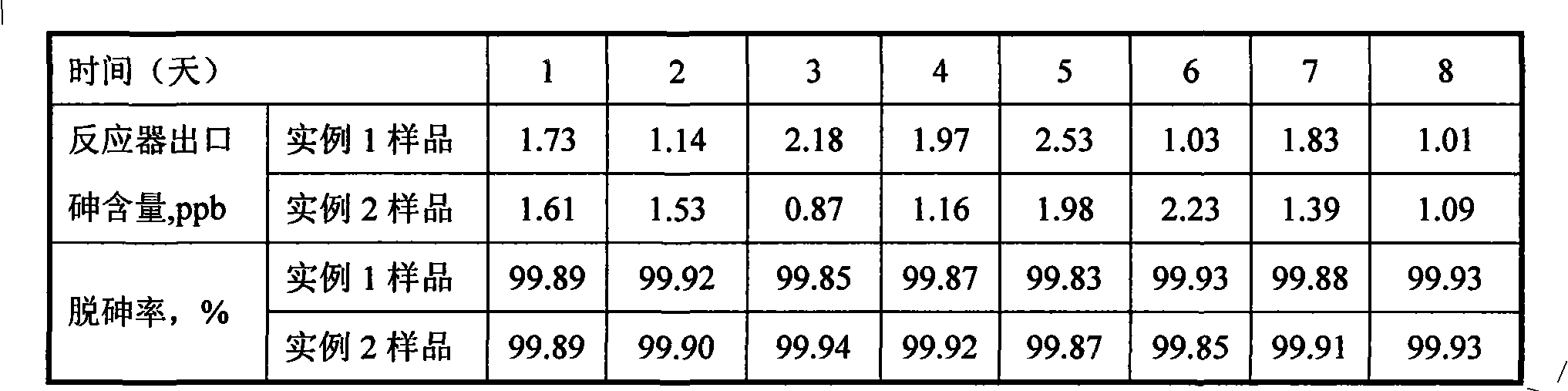

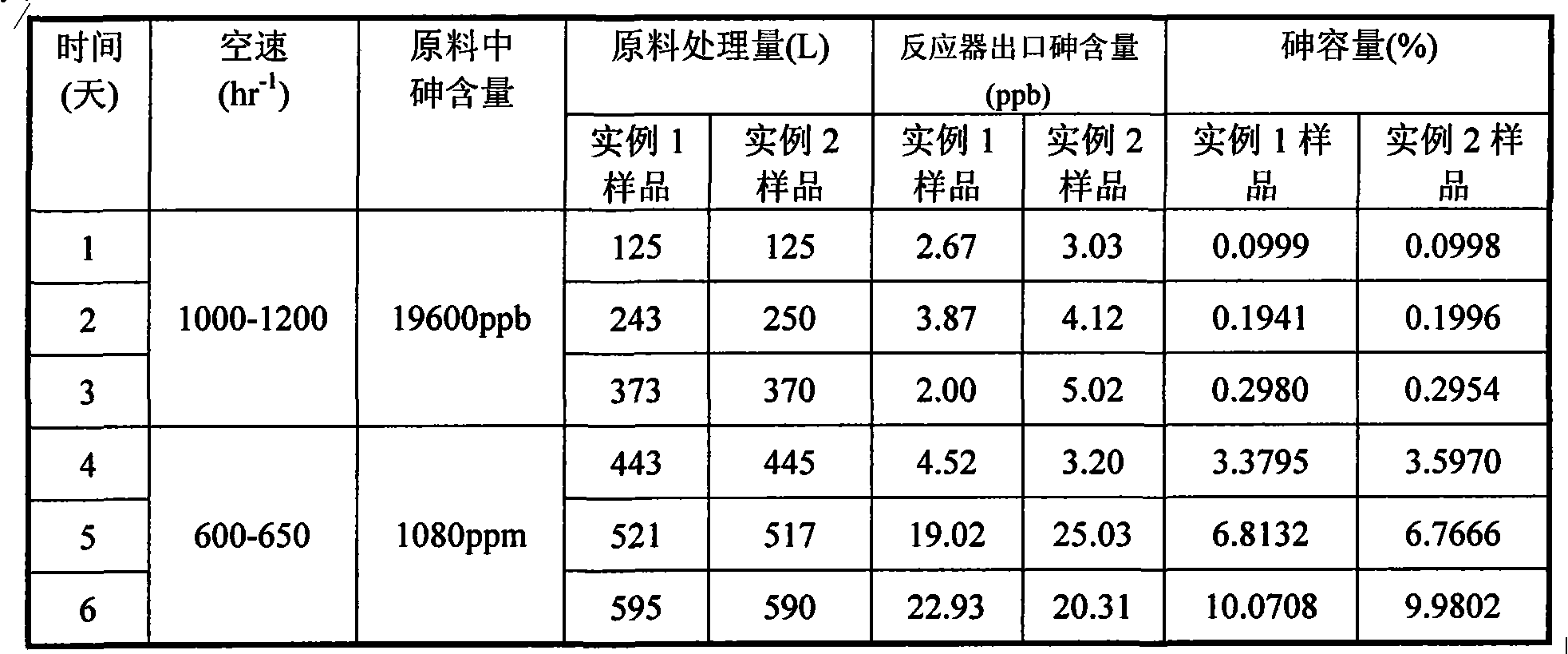

[0034] The experimental example of the effect of removing arsenic of the present invention:

[0035] 1. Do the initial ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com