Halogen-free ethoxyline resin antiflaming bonding adhesive and adhesive film thereof

A technology of flame retardant adhesives and halogen epoxy resins, applied in the direction of epoxy resin adhesives, adhesives, adhesive types, etc., can solve the problems of poor heat resistance, general adhesion, and environmental impact of cured products, and achieve good results. Effects of heat resistance, superior adhesive performance, and good flame-retardant durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation process of the halogen-free epoxy resin flame-retardant adhesive of the present invention is as follows:

[0021] (1) Dissolve nitrile rubber in a solvent, then mix various epoxy resins in proportions and add them, and stir at 40-60°C to make a solution;

[0022] (2) The solution in step (1) is heated to 70-80°C, stirred for 2-4 hours, and then cooled to 45°C, and a curing agent and a curing accelerator are added.

[0023] Follow steps (1) and (2) to prepare halogen-free epoxy resin flame retardant adhesive.

[0024] A halogen-free heat-resistant adhesive film includes a release paper and a flame-retardant adhesive coated on the release paper, wherein the flame-retardant adhesive is the flame-retardant adhesive of the present invention.

[0025] The binder for forming a halogen-free heat-resistant adhesive film, including 100 parts by weight of epoxy resin, 35-50 parts by weight of nitrile rubber, 8-15 parts by weight of curing agent, 0.5-2.0 parts by weight...

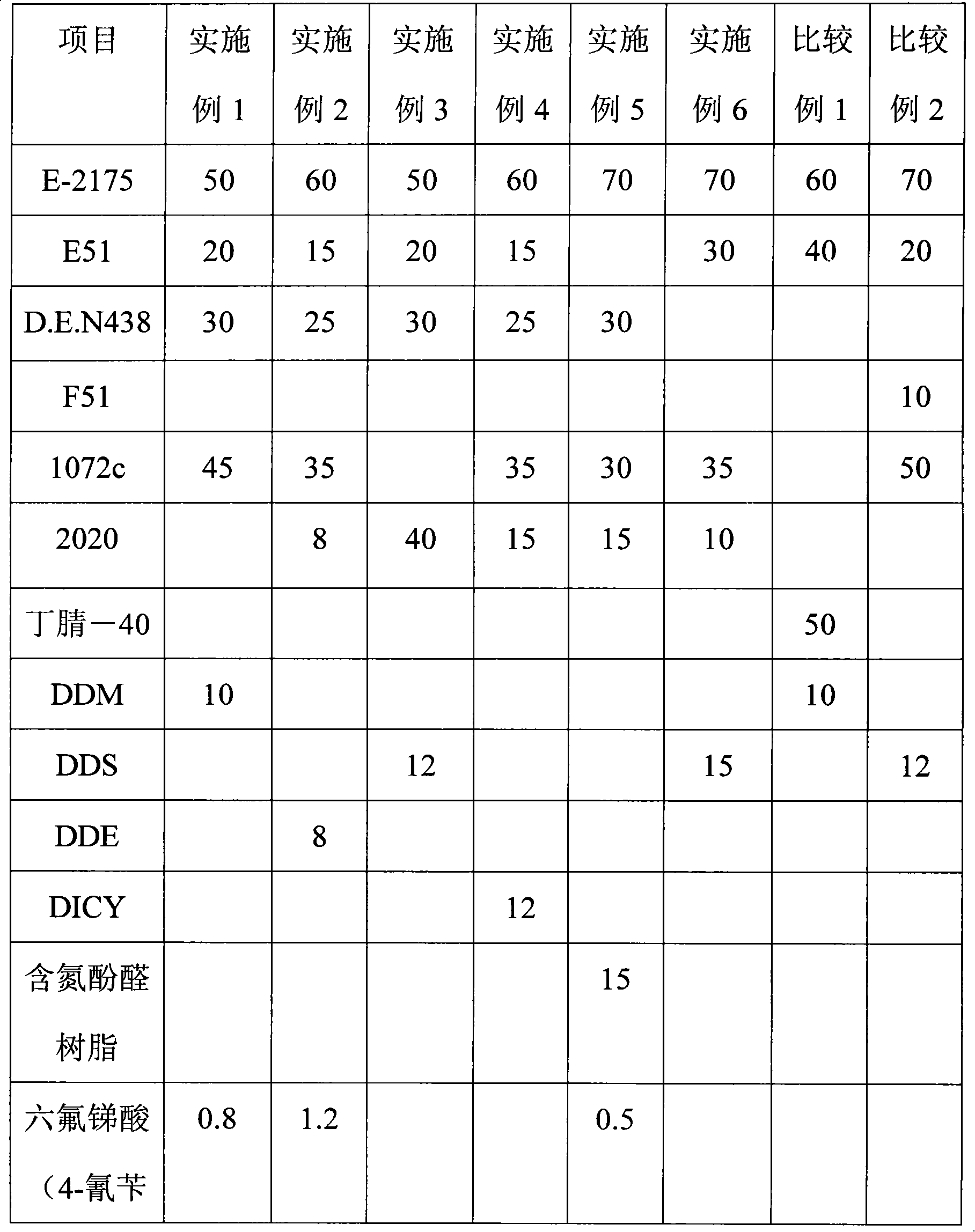

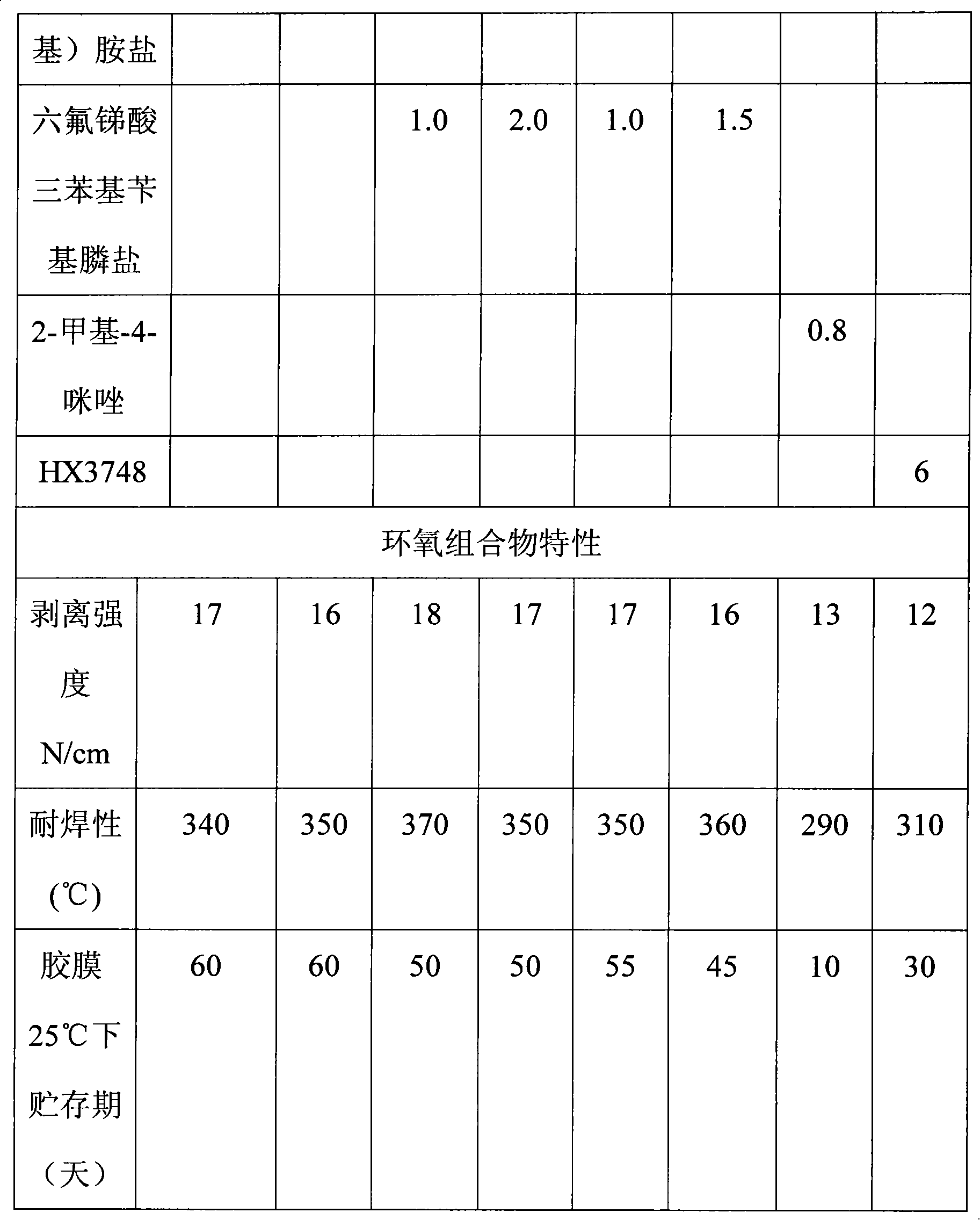

Embodiment 1

[0036] 35 parts of carboxyl-terminated nitrile rubber (commodity model 1072c, produced by Zeon Corporation, acrylonitrile content 27%wt, carboxyl content 3.4%wt), hydrogenated nitrile rubber (commodity model: 2020, produced by Zeon Corporation Japan, carboxyl Content 3.5%wt) 10 parts are mixed and dissolved in 180 parts of methyl ethyl ketone solvent; then phosphorus-containing epoxy resin (commodity model E-2175, produced by Wuxi Akoli Chemicals, phosphorus content 3.5%wt, epoxy equivalent 320) 50 parts, bisphenol A epoxy resin (model E51, produced by Wuxi Resin Factory, epoxy equivalent 275) 20 parts, phenolic epoxy resin (commodity model DEN438, produced by The Dow Chemical Company, epoxy equivalent 180, ring Oxygen functionality 3.6) 30 parts were mixed and added to the above mixture, stirred at 40 ℃ for 2 hours to make a solution; the above solution was heated to 70 ℃, stirred for 3 hours and then cooled to 45 ℃, add 10 parts of curing agent DDM and The curing accelerator is ...

Embodiment 2

[0039] 35 parts of carboxyl-terminated nitrile rubber (commodity model 1072c, produced by Zeon Corporation, acrylonitrile content 27%wt, carboxyl content 3.4%wt), hydrogenated nitrile rubber (commodity model: 2020, produced by Zeon Corporation Japan, carboxyl Content 3.5%wt) 8 parts are mixed and dissolved in 170 parts of methyl ethyl ketone solvent; then phosphorus-containing epoxy resin (commodity model E-2175, produced by Wuxi Akoli Chemicals, phosphorus content 3.5%wt, epoxy equivalent 320) 60 parts, 15 parts of bisphenol A epoxy resin (model E51, produced by Wuxi Resin Factory, epoxy equivalent 275), phenolic epoxy resin (commodity model DEN438, produced by The Dow Chemical Company, epoxy equivalent 180, ring Oxygen functionality 3.6) 25 parts were mixed and added to the above mixture, stirred at 50 ℃ for 1.5 hours to make a solution; the above solution was heated to 75 ℃, stirred for 2 hours and then cooled to 45 ℃, add 8 parts of curing agent DDE and The curing accelerator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com