Leather retanning fat-liquoring agent and preparation method thereof

A technology for retanning and fatliquoring and leather, which is applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, tanning treatment, etc. Problems such as late start, high storage stability, pleasant smell, and improved elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

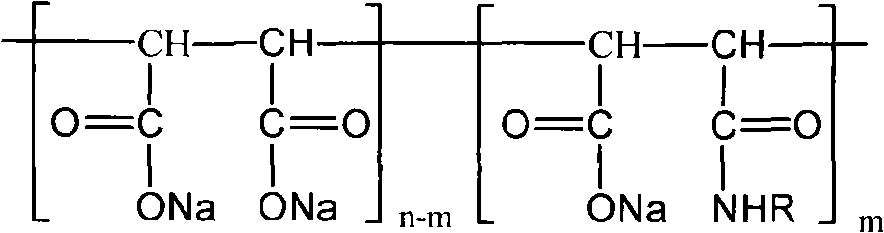

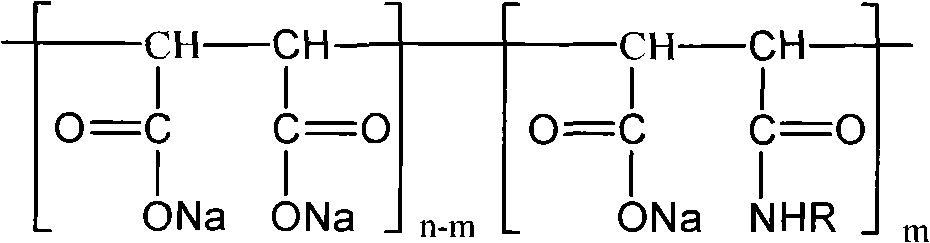

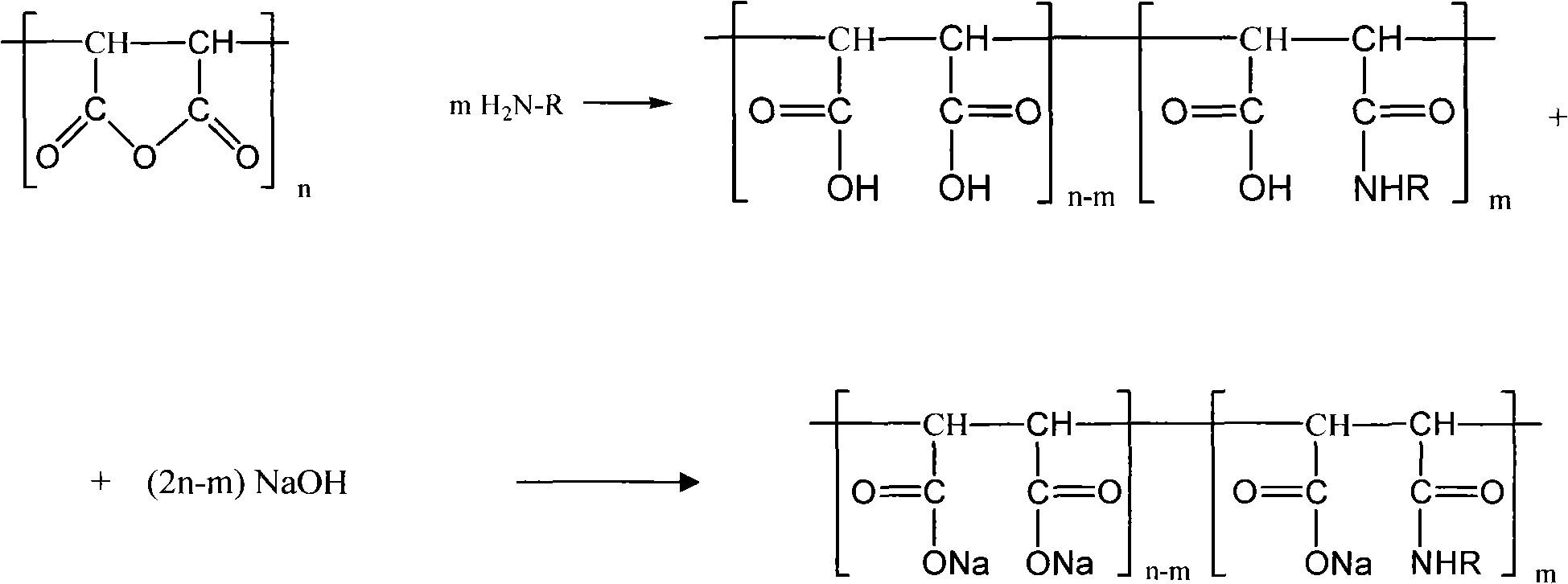

Method used

Image

Examples

Embodiment 1

[0016] At 60 °C, 25 g of polymaleic anhydride was completely dissolved with 50 g of N,N-dimethylformamide, 46 g of dodecylamine and 0.6 g of p-toluenesulfonic acid were added, and the reaction was continued at 90 °C for 3.5 hours after mixing evenly. ; Remove 55% of N, N-dimethylformamide by distillation under reduced pressure, be cooled to 55 ℃, use the sodium hydroxide that mass concentration is 30% to adjust the pH value of the solution to be about 6.5, and finally add water to adjust the solid content of the product as 20%.

Embodiment 2

[0018] At 65 °C, 25 g of polymaleic anhydride was completely dissolved with 60 g of diethylene glycol dimethyl ether, 50 g of tetradecylamine and 0.8 g of p-toluenesulfonic acid were added, and the reaction was continued at 95 ° C for 4 hours after mixing uniformly; Press distillation to remove 65% of diethylene glycol dimethyl ether, cool down to 60°C, adjust the pH value of the solution to about 6.5 with 30% sodium hydroxide, and finally add water to adjust the solid content of the product to 20%.

Embodiment 3

[0020] At 55°C, 25g of polymaleic anhydride was completely dissolved with 47g of N,N-dimethylformamide, 62g of hexadecylamine and 0.8g of sulfuric acid were added, and the reaction was continued at 90°C for 3.5 hours under reduced pressure. 60% of N,N-dimethylformamide was distilled off, cooled to 50°C, the pH of the solution was adjusted to about 7.0 with 30% sodium hydroxide, and finally water was added to adjust the solid content of the product to 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com