Novel fiber grating two-dimensional tilting angle sensor

A fiber grating and tilt angle technology, which is applied to measure the inclination and use optical devices to transmit sensing components, instruments, etc., can solve the problems of mechanical contact, friction error, rigid connection and stability requirements of the device, and eliminate the influence , the effect of simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

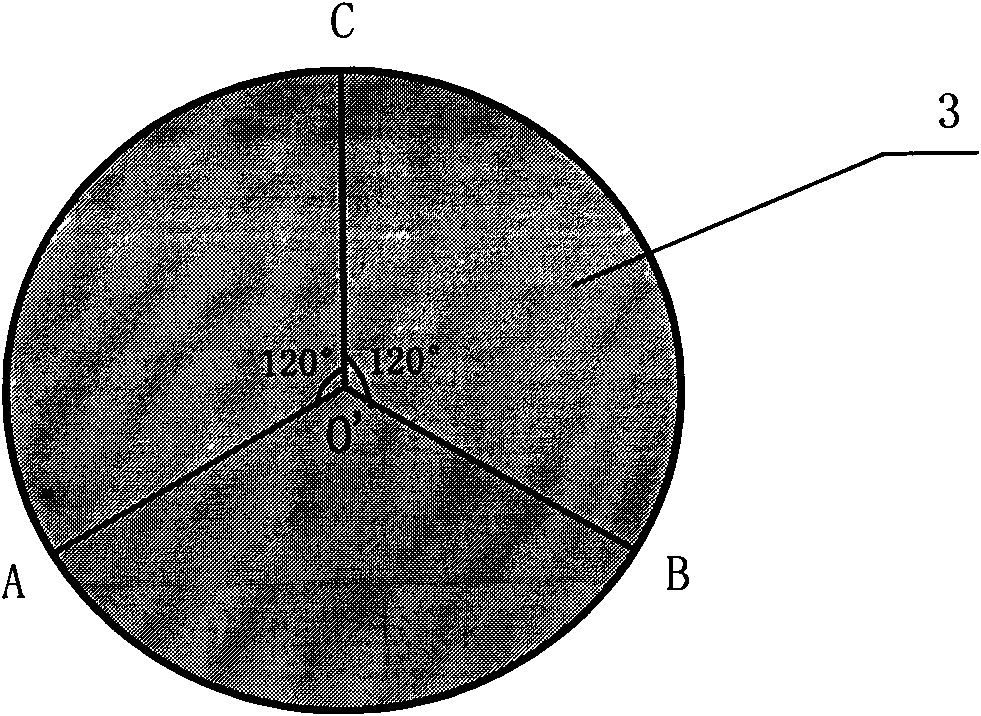

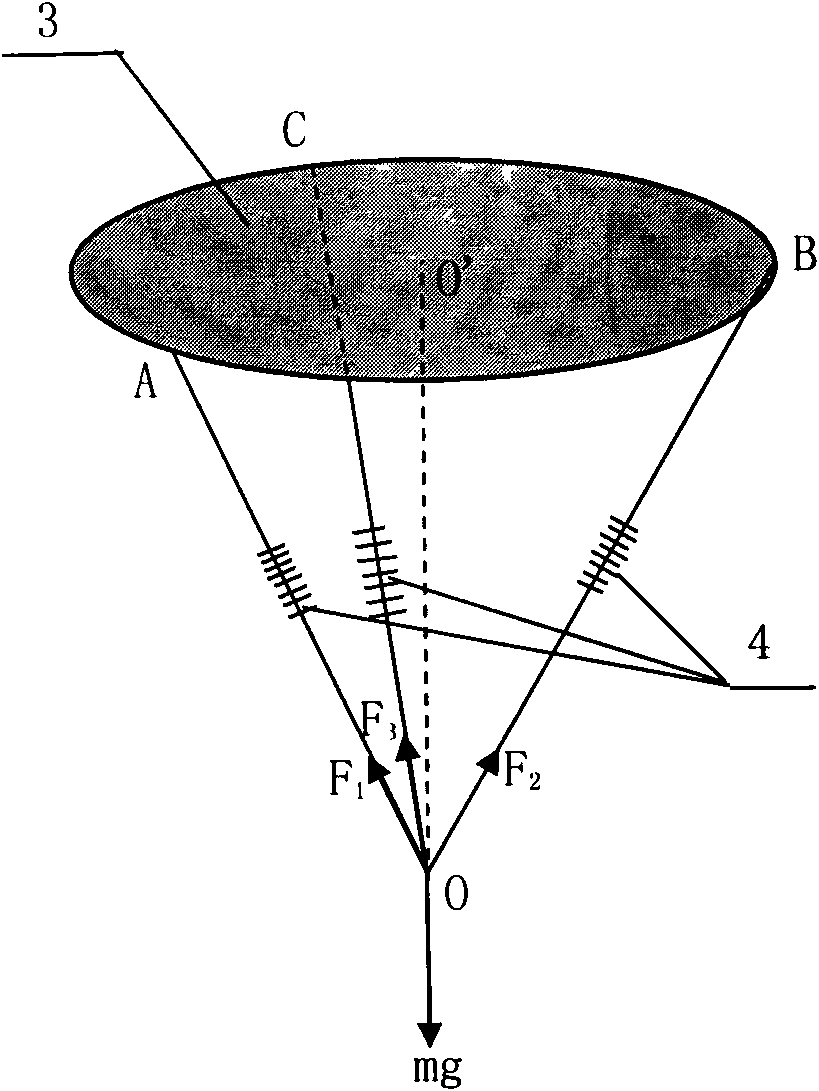

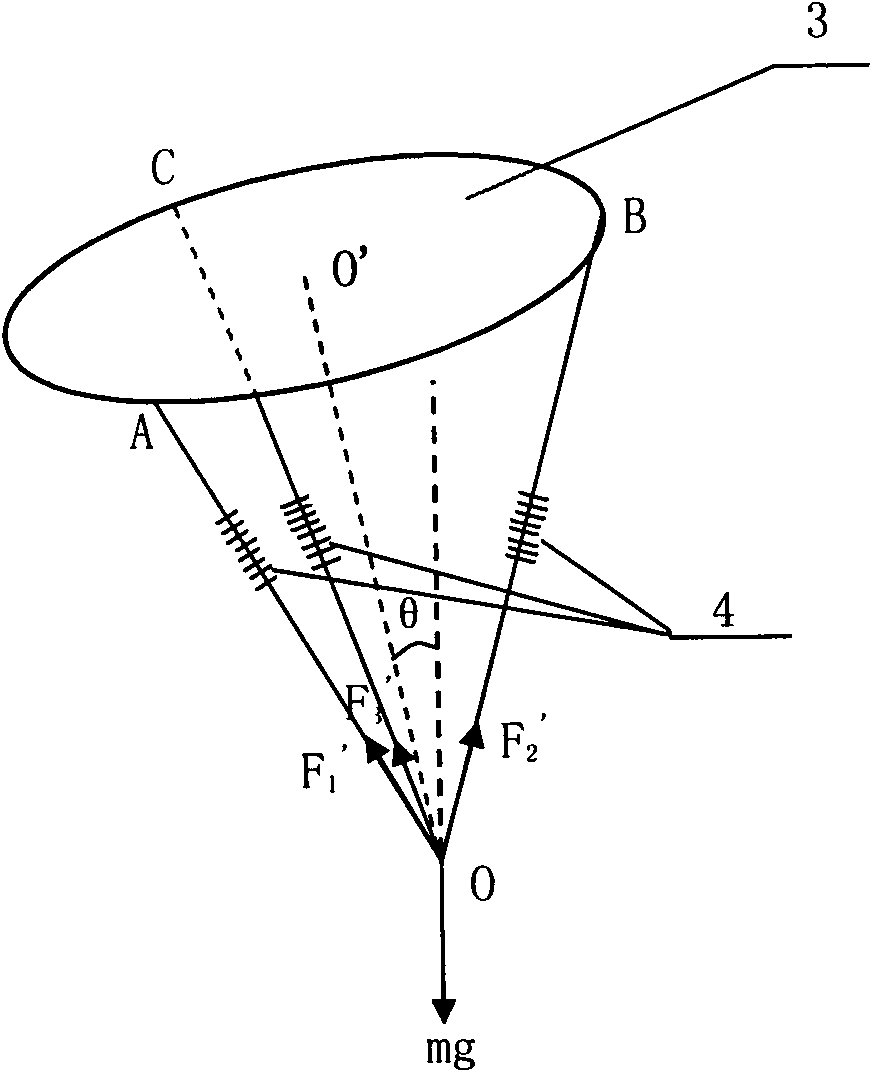

[0020] Attached below figure 2 , 3 , 4 further illustrate the technical solution of the present invention.

[0021] Refer to attached figure 2 , during concrete implementation, we use metal disc as the material of top plate (3) and chassis (1), and pillar selects metal bar for use. The metal rod is rigidly connected with the top plate (3) and the bottom plate (1), and the pigtails of each optical fiber grating (4) are bonded with the top plate (3) and the weight (5) with superglue. Connect the optical fiber (6) to the fiber grating demodulator (7), and connect the fiber grating demodulator (7) to the computer (8). In this way, the light sent by the fiber grating demodulator (7) is transmitted to each fiber grating (4) through an optical fiber, and the center wavelength that meets the Bragg condition is reflected back, and is transmitted back to the fiber grating demodulator (7) through an optical fiber, and then from the computer (8) Read out the magnitude of the central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com