Method and device for large-range and high-resolution atomic force micro detection for large sample

A technology of atomic force microscopy and detection devices, which is applied in the direction of measuring devices, analytical materials, instruments, etc., can solve the problems of detection optical path deviation, inability to realize micro-probe scanning, and separation from micro-probes, etc., and achieve high sensitivity and high resolution , the technical conditions are easy to realize, and the effect of avoiding system errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

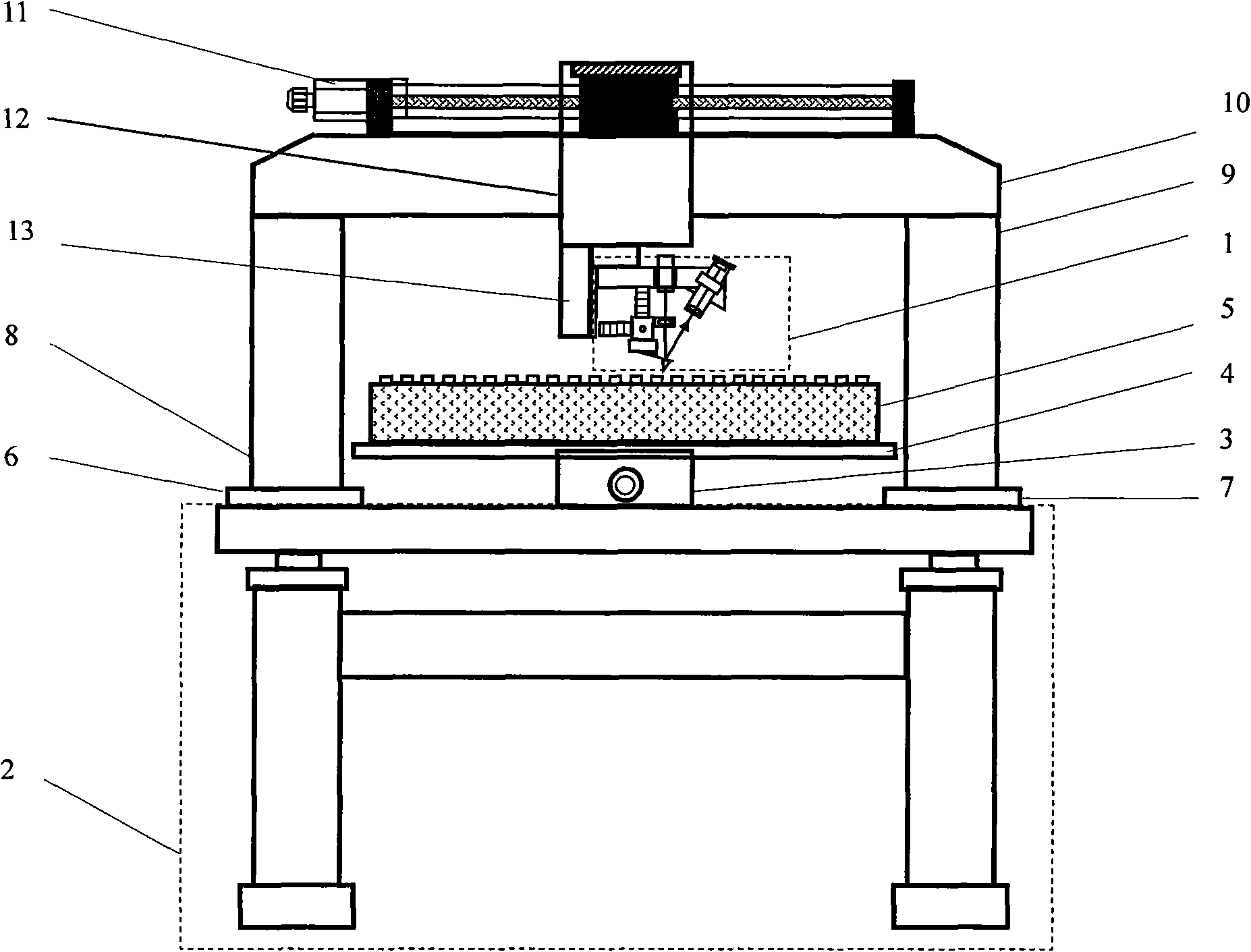

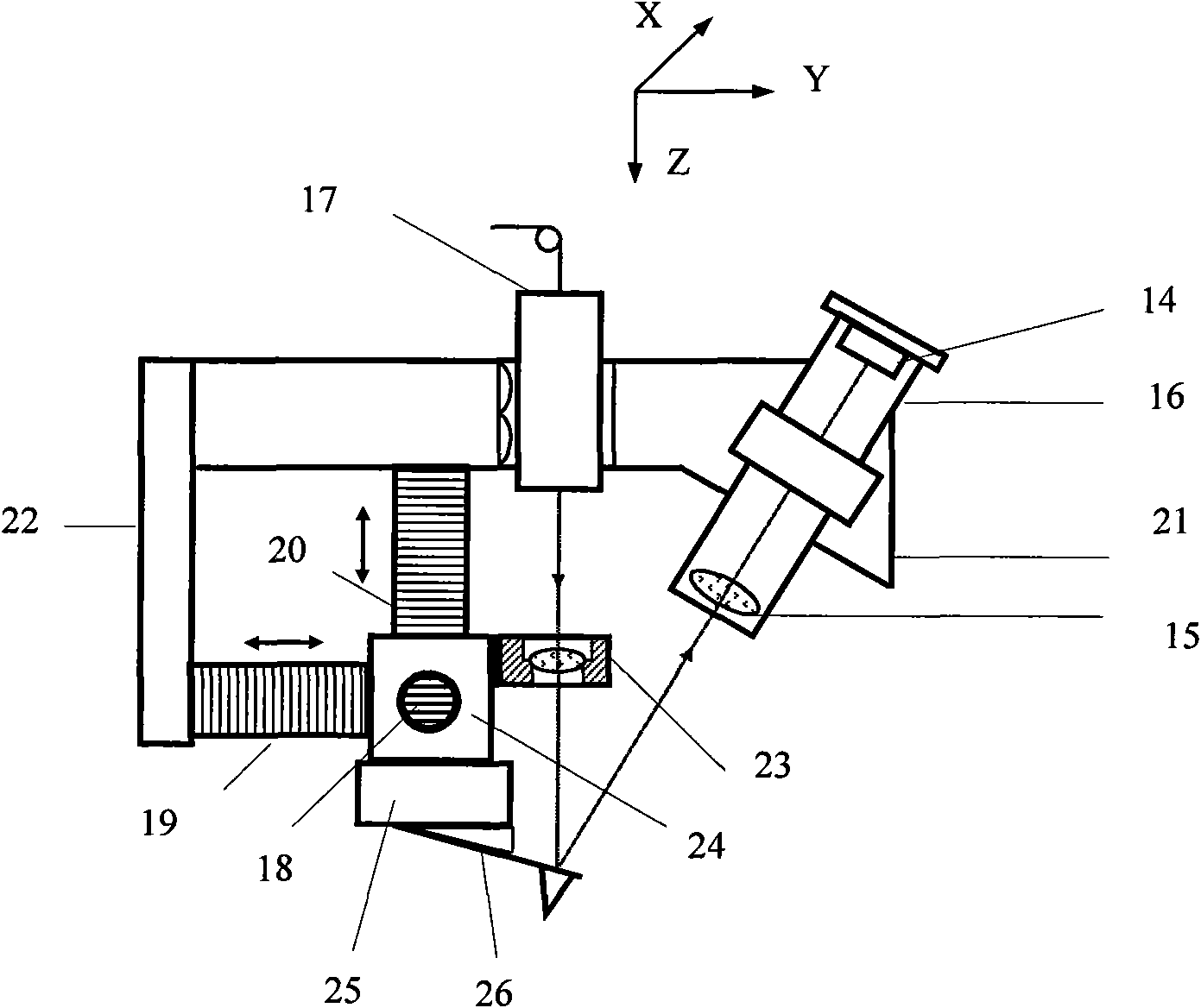

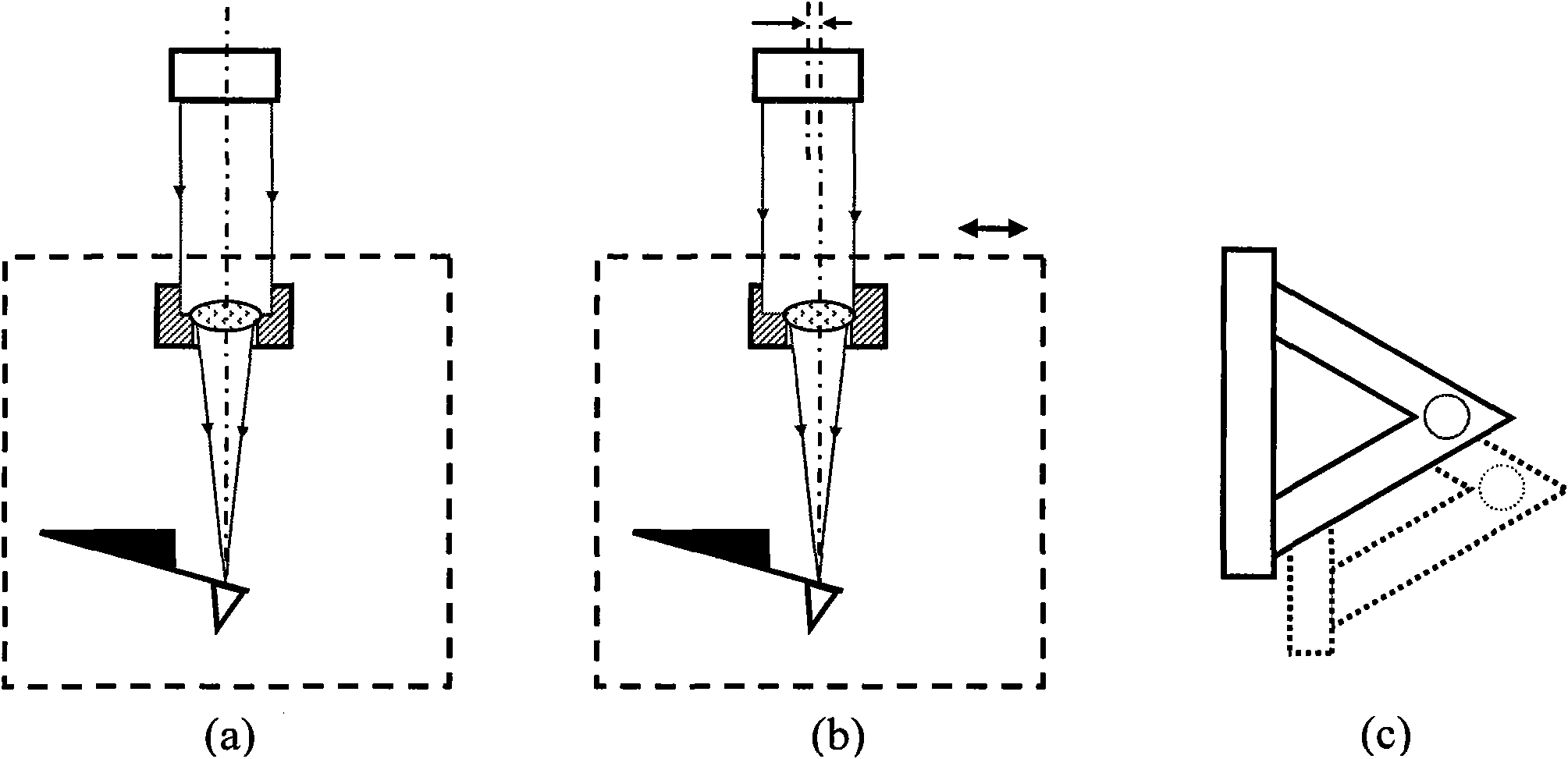

[0017] The method of large-scale high-resolution atomic force microscopy for large samples adopts the method of fixing the sample and scanning the micro-probe, and introduces a small lens that scans together with the scanner. Its XY scanning movement is always the same as that of the micro-probe, that is, the micro-probe The needle is always at the focal point of the small lens. During the wide-range scanning process, the laser spot focused by the small lens is always aligned with the micro-cantilever, thus effectively realizing the tracking of the optical path. Another small spot in front of the photodetector The lens not only avoids the systematic error caused by the Z-direction feedback, but also maintains the high sensitivity and high resolution of the beam deflection method, thereby realizing a large-scale high-precision Z-direction feedback control and a large-scale high-resolution XY scanning imaging ( Horizontal 0.2nm, vertical 0.1nm), using an open sample stage and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com