Self-fitting digital temperature compensation crystal oscillistor and system and realization method thereof

A technology of digital temperature compensation and crystal oscillator, which is applied in the direction of electronic circuit testing, output stability, electrical components, etc., can solve the problems of increasing manual operation errors, cumbersome production process, large deviation of temperature compensation data compensation data, etc., to achieve temperature Best stability and accuracy, improved production efficiency, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

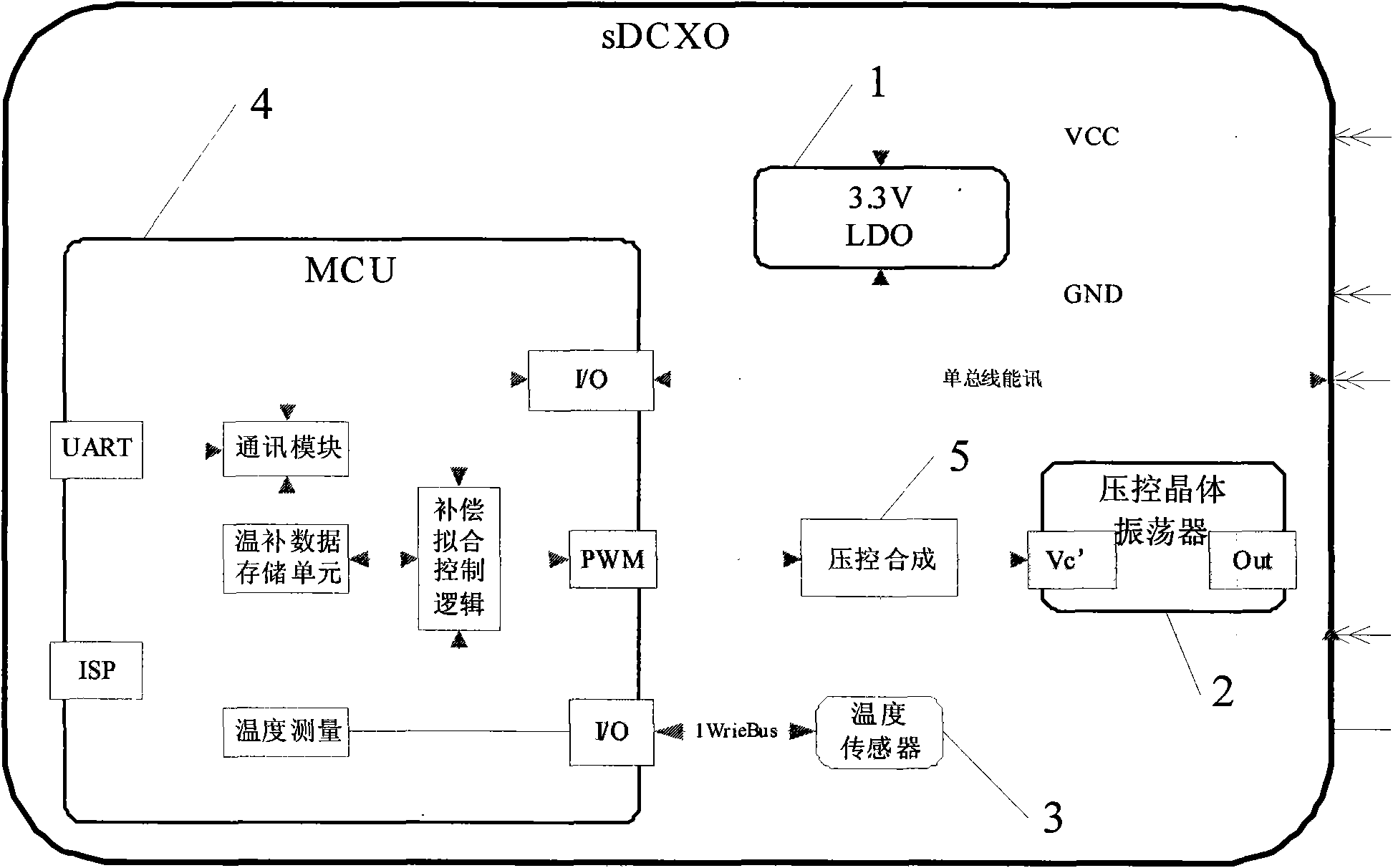

[0037] The present invention provides a digitally compensated voltage-controlled temperature-compensated crystal oscillator with self-fitting test, its principle block diagram is as follows figure 1 As shown, the self-fitting digitally compensated voltage-controlled temperature-compensated crystal oscillator (sDCXO) includes a voltage regulator 1, a compensated voltage-controlled crystal oscillator 2, a temperature sensor 3, a microcontroller 4, and a voltage-controlled synthesis circuit 5, wherein:

[0038]The voltage stabilizer 1 is a voltage stabilizing circuit in the whole product. The external power supply of the self-fitting digital temperature compensated crystal oscillator passes through the power supply input terminal VCC and the voltage stabilizer 1 becomes a compensated voltage-controlled temperature-compensated crystal oscillator 2, temperature The sensor 3, the microcontroller 4, and the voltage control synthesis circuit 5 provide a stable DC operating voltage or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com