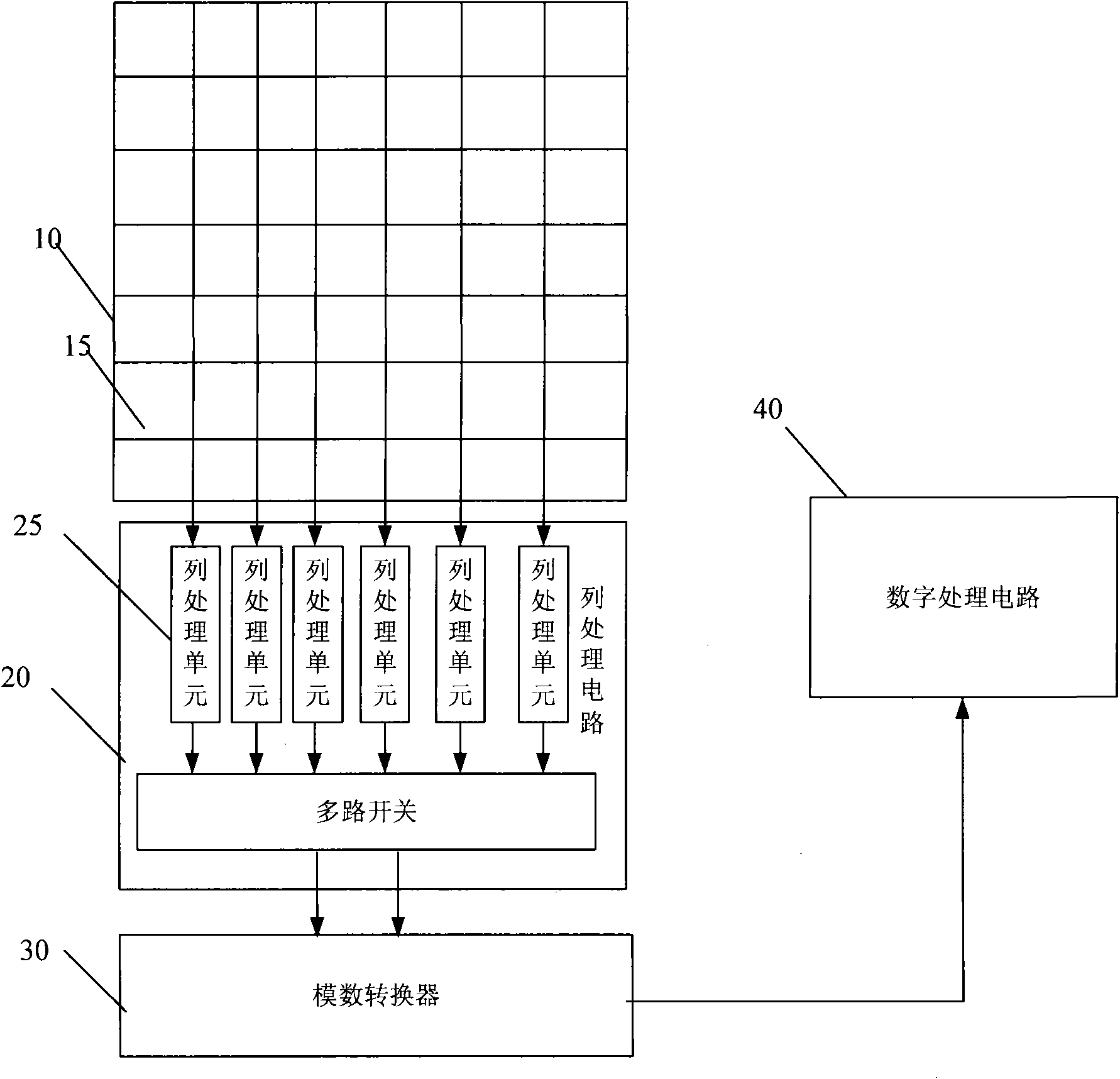

Image sensor and column processing circuit thereof

A column processing and circuit technology, which is applied in the field of column processing circuits and image sensors, can solve problems such as easy distortion of light intensity signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

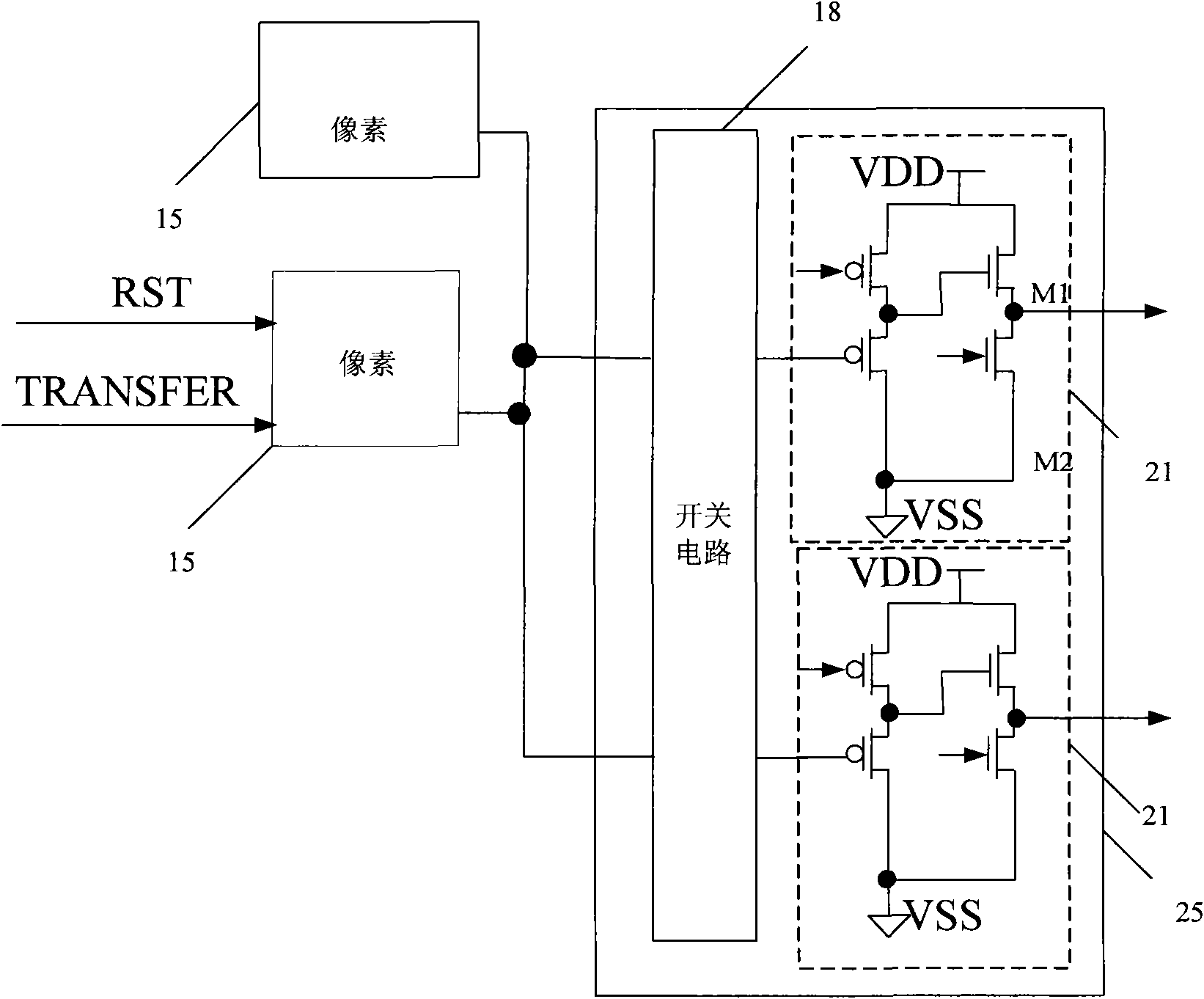

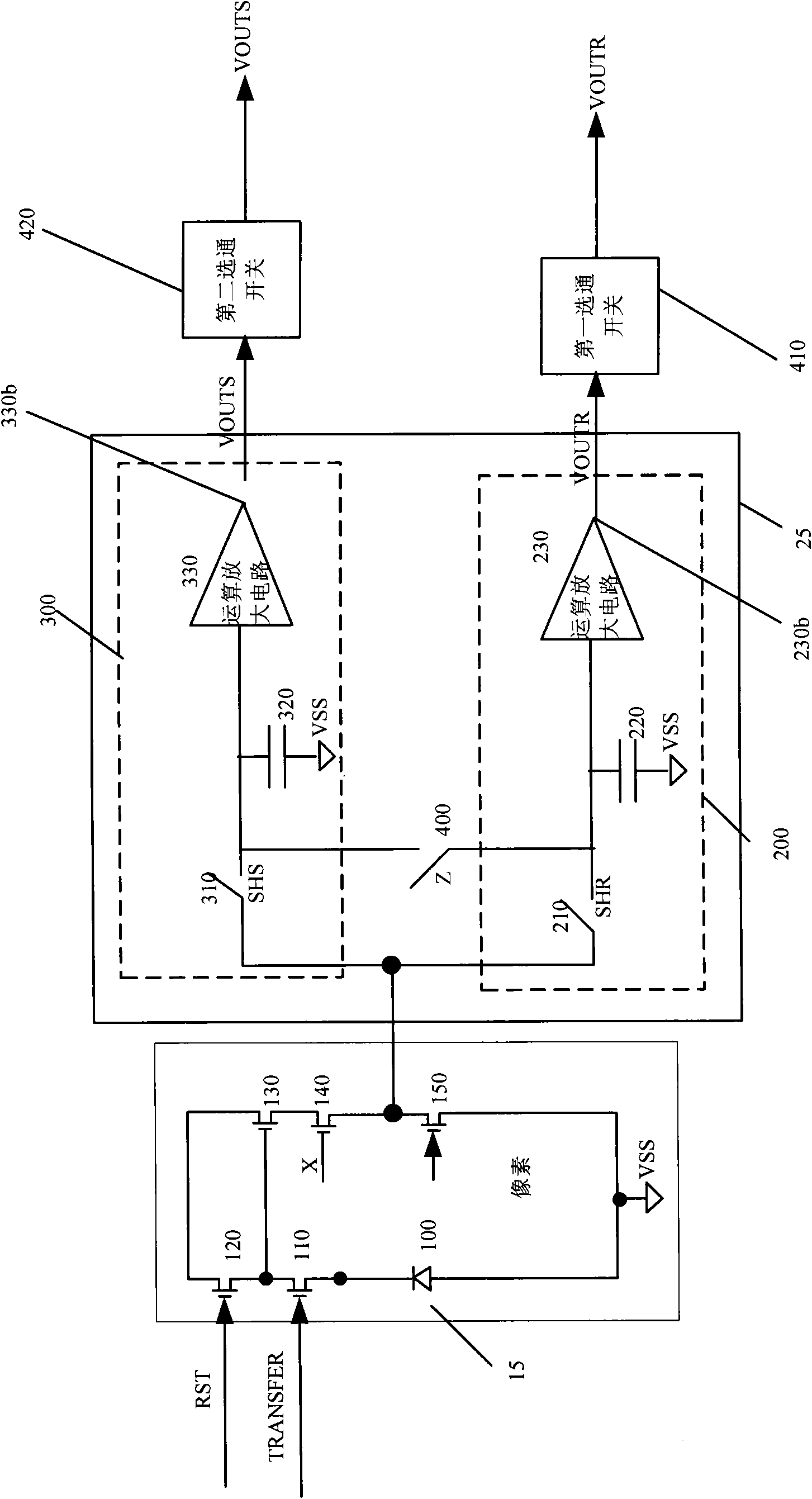

[0039] image 3 Shown is a schematic structural diagram of a pixel and a column processing unit in the image sensor according to the first embodiment of the present invention.

[0040] Such as image 3 As shown, the pixel 15 includes: a photodiode 100 , a first NMOS transistor 110 , a second NMOS transistor 120 , a third NMOS transistor 130 , a fourth NMOS transistor 140 and a bias NMOS transistor 150 .

[0041] Wherein, the anode of the photosensitive diode 100 is connected to the low level VSS, the negative electrode of the photosensitive diode 100 is connected to the source of the first NMOS transistor 110; the gate of the first NMOS transistor 110 is connected to the transmission signal input terminal (TRANSFER), and the first NMOS transistor 110 The drain of the second NMOS transistor 120 is connected to the source of the second NMOS transistor 120; the drain of the second NMOS transistor 120 is connected to the high level VDD, and the gate of the second NMOS transistor ...

no. 2 example

[0067] Figure 9 Shown is a schematic diagram of a second embodiment of the column processing circuit of the present invention. In this embodiment, the same parts as those in the first embodiment will not be repeated. The difference is that in this embodiment, a second-stage operational amplifier circuit 430 is also included, and the input terminals of the second-stage operational amplifier circuit 430 are connected to at least two The output of the operational amplifier circuit 230 of the reference voltage unit 200 , for example, can be connected to 2 operational amplifier circuits 230 , to 3 operational amplifier circuits 230 , to 6 operational amplifier circuits 230 and so on. Such as Figure 9 As shown, the input terminal of the second-stage operational amplifier circuit 430 is connected to the outputs of the operational amplifier circuits 230 of the two reference voltage units 200 . The output end of the second-stage operational amplifier circuit 430 is connected to the...

no. 3 example

[0071] Figure 10 Shown is a schematic diagram of a third embodiment of the column processing circuit of the present invention. In this embodiment, the same parts as those in the first embodiment will not be described again. The difference is that in this embodiment, the column processing unit 25 also includes a third-stage operational amplifier circuit 440, and the first stage of at least two reference voltage units 200 The output end of the two-stage operational amplifier circuit 430 is connected to the input end of the third-stage operational amplifier circuit 440, and the output end of the third-stage operational amplifier circuit 440 is connected to the first selection switch 410, wherein the third-stage operational amplifier circuit 440 is Connected as an operational amplifier circuit in the form of a voltage follower. For example, it may have the same structure as the second-stage operational amplifier circuit 430 connected thereto. Similarly, the light intensity volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com