Two-way gas flow control valve and ventilation system of crankcase of engine

A crankcase ventilation and gas flow technology, which is applied in crankcase ventilation, engine components, machines/engines, etc., can solve the problem of high negative pressure in the crankcase of a supercharged engine, avoid oil leakage, facilitate manufacturing and processing, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

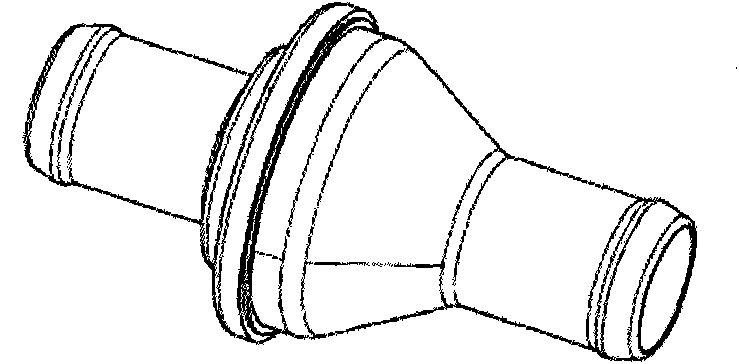

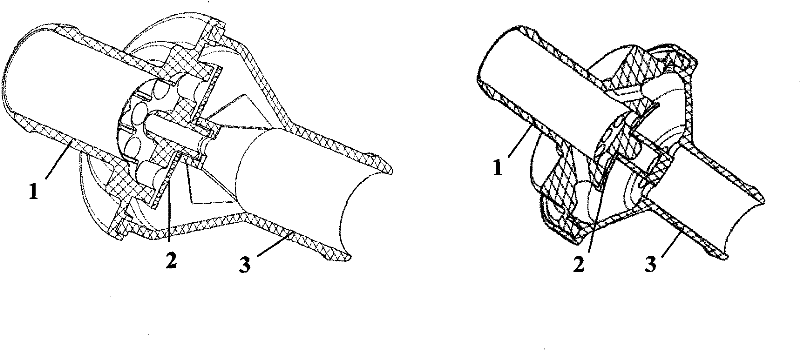

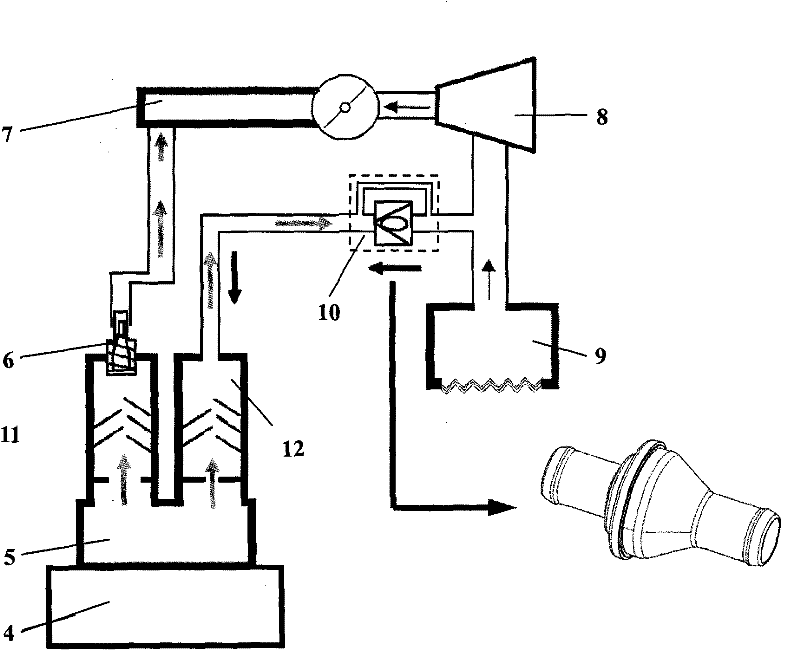

[0026] For an example of a crankcase ventilation system implemented in a turbocharged engine, see Figure 1 , is a schematic diagram of the two-way gas flow control valve of the present invention; Figure II , is a structural schematic diagram of the two-way gas flow control valve of the present invention, including an upper casing 1, a diaphragm 2, and a lower casing 3; Figure three , a schematic diagram of the layout of the crankcase ventilation system of a turbocharged engine, which shows the crankcase 4, the valve chamber cover 5, the PCV valve 6, the intake manifold 7, the supercharger 8, the air filter 9, and the two-way gas flow control Valve 10 etc. The above-mentioned components are connected by peripheral pipelines to form a closed-loop control.

[0027] The specific princi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com