Quantity production packaging technique of minitype OLED display

A packaging process and display technology, which is used in the manufacture of electrical solid devices, semiconductor devices, semiconductor/solid state devices, etc. The effect of reducing the packaging cost and improving the strength of the bonding wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

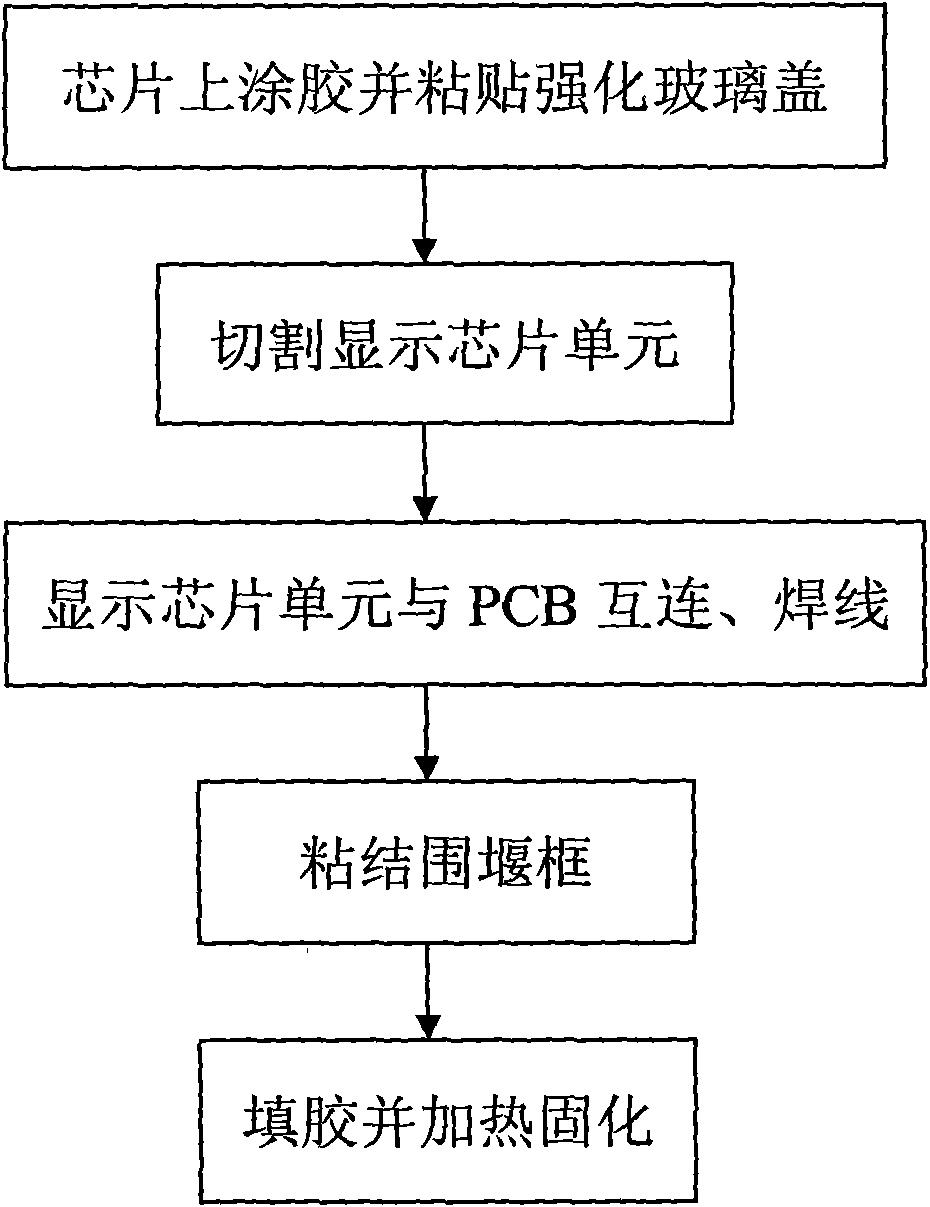

[0022] like figure 1 As shown, follow the steps below to package the micro OLED display

[0023] In the first step, thermal glue is vibrated on the display chip on the silicon wafer, and the cover glass is bonded.

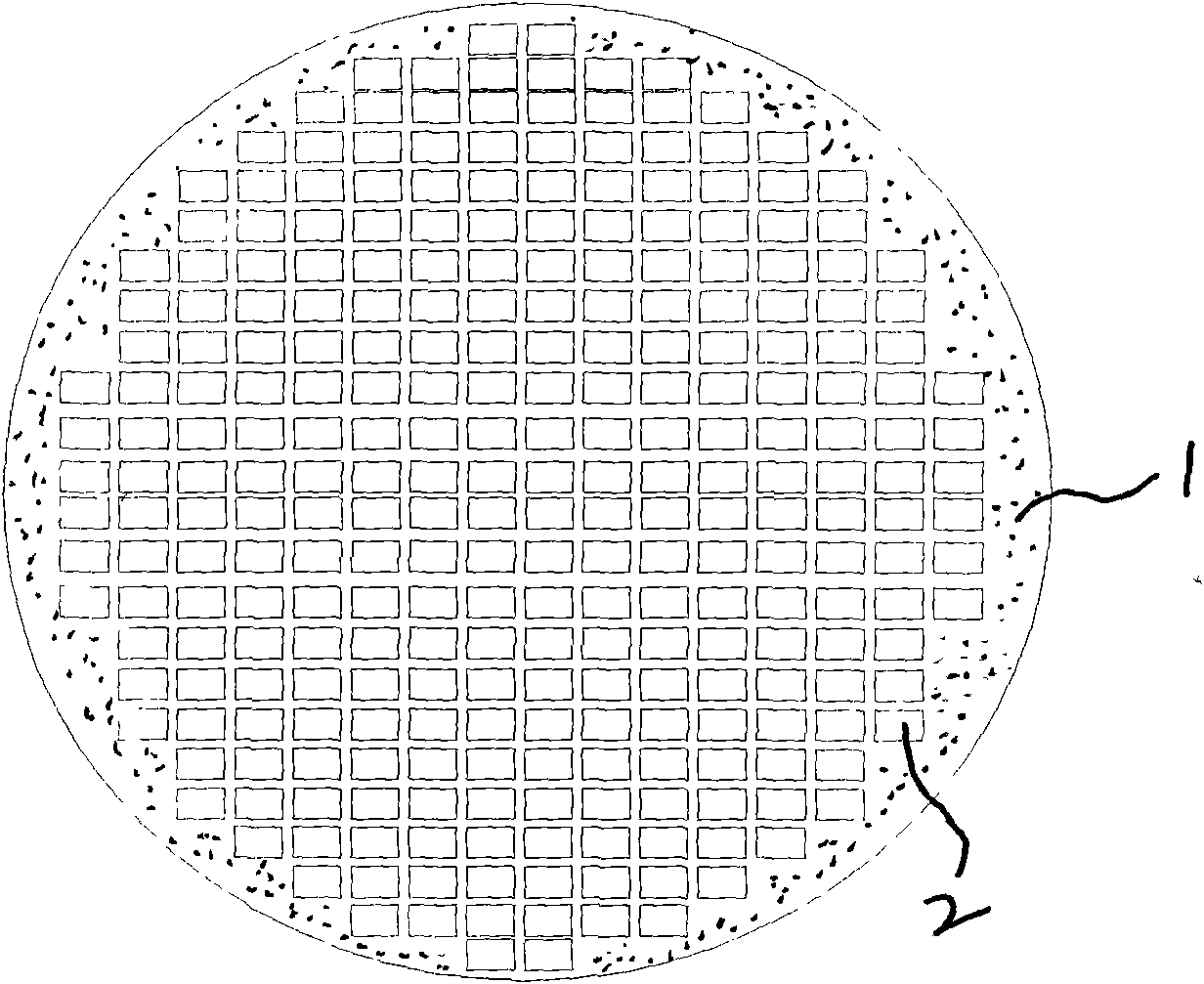

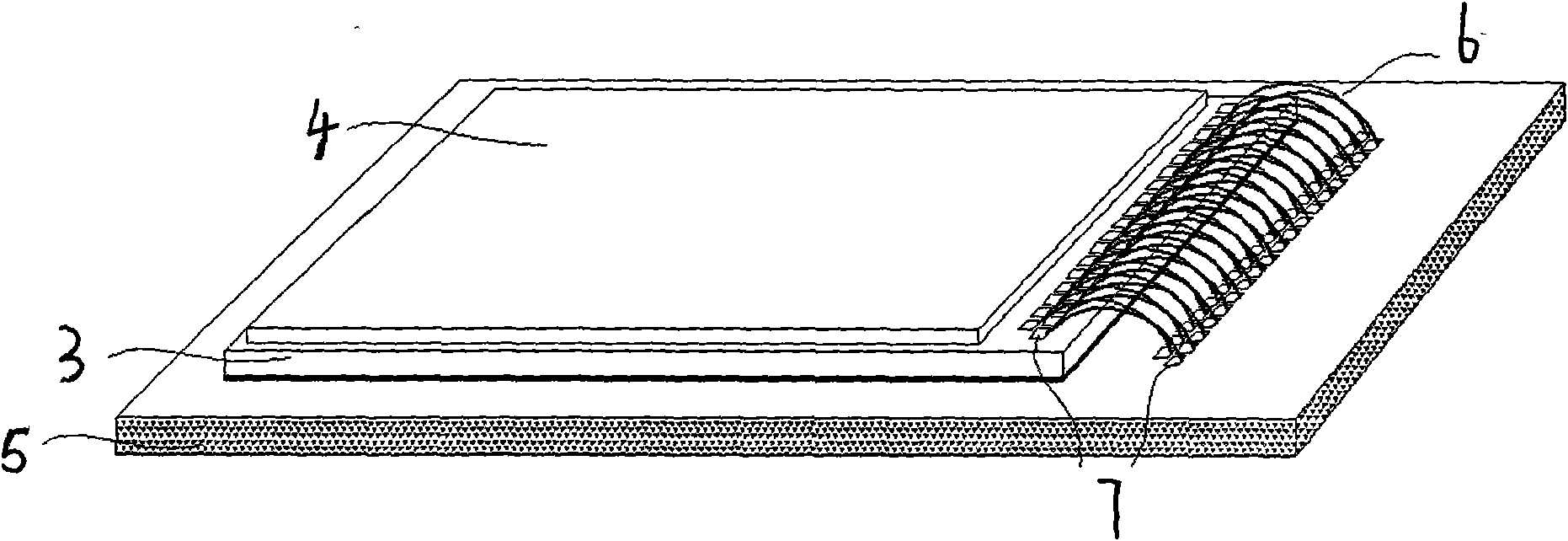

[0024] Place the 8-inch silicon wafer (1) covered with the display chip (2) on the hot plate of the adhesive mounter, the temperature of the hot plate is 65°C, and heat for 5 minutes to make the temperature uniform. The bonding glue is Dow Corning Sylgard-182, which is a transparent high-strength bonding silicone. Mix the Curing agent into the Base according to the weight ratio of 1:10, use a glue tank to mix thoroughly, put it into the glue dispenser of the glue mounter, adjust the glue output to 15mg / small piece, carry out vibratory glue coating, and glue The strengthened glass cover (4) is bonded at the same time, and the glass cover (4) adopts K9 glass that has undergone surface smoothing and stress treatment. After finishing the cover work of the display ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com