Placement device and placement method

A placement device and placement technology, applied in the field of electronic component placement devices, can solve the problems of low control accuracy and cost increase, and achieve the effects of easy disassembly and replacement, compact structure, and saving maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The electronic component placement device of the technical solution will be further described in detail below in conjunction with the drawings and embodiments.

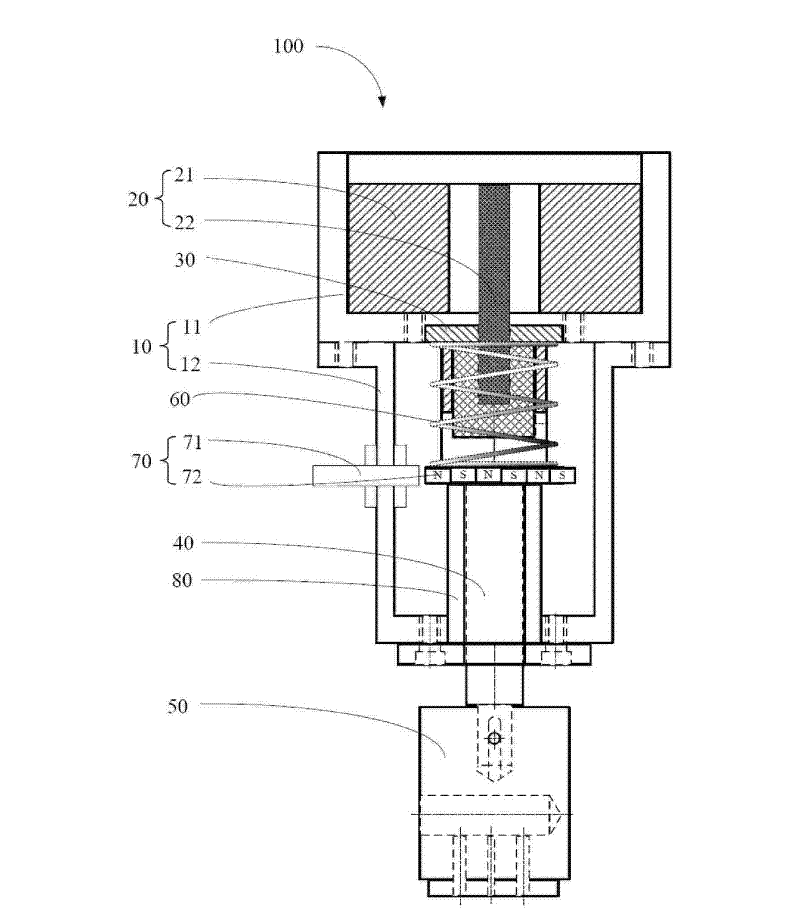

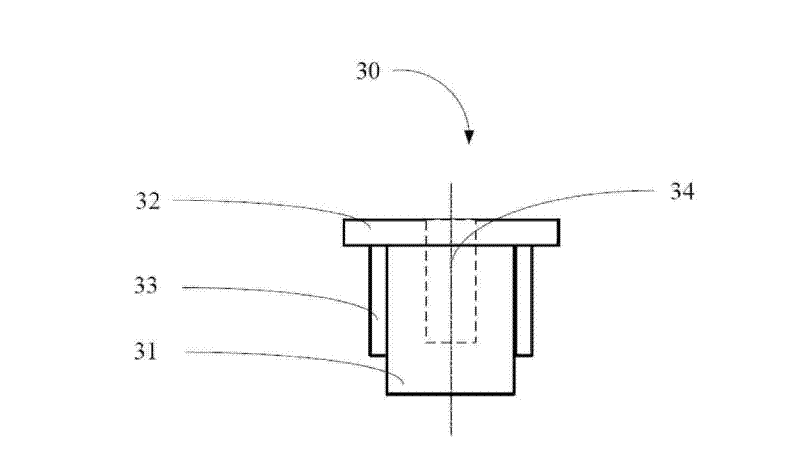

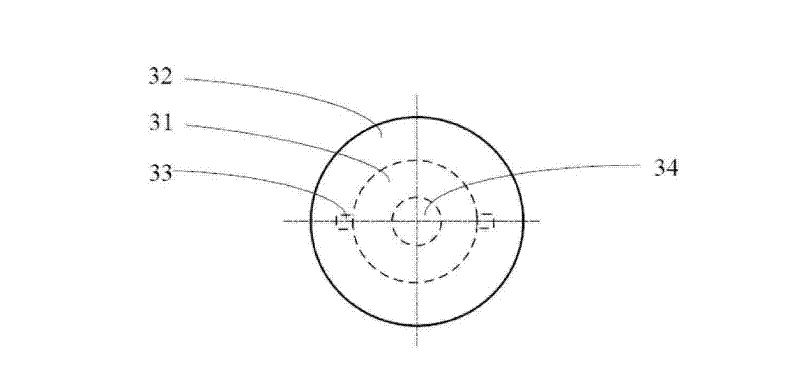

[0018] see figure 1 , the embodiment of the technical solution provides a mounting device 100 for mounting electronic components on a printed circuit board. The placement device 100 includes a fixed frame 10 , a servo motor 20 , a coupling 30 , a placement spindle 40 , a placement suction nozzle 50 , a protection spring 60 , a sensor device 70 and a bushing 80 .

[0019] The fixing frame 10 includes a first receiving frame 11 and a second receiving frame 12 . The shape and size of the first receiving frame 11 correspond to the servo motor 20 and are used to accommodate the servo motor 20 . The shape and size of the second receiving frame 12 correspond to the coupling 30 and the mounting spindle 40 , and are used to accommodate the coupling 30 and part of the mounting spindle 40 .

[0020] The servo motor 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com