Production equipment and production technology for healthy rice

A technology of production process and production equipment, applied in the field of production equipment and production technology of healthy rice, can solve the problems of limited nutrient content of parboiled rice, inconsistency with energy saving and environmental protection, and high energy consumption of production equipment, and achieves the promotion of health and longevity with clever design. , the effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

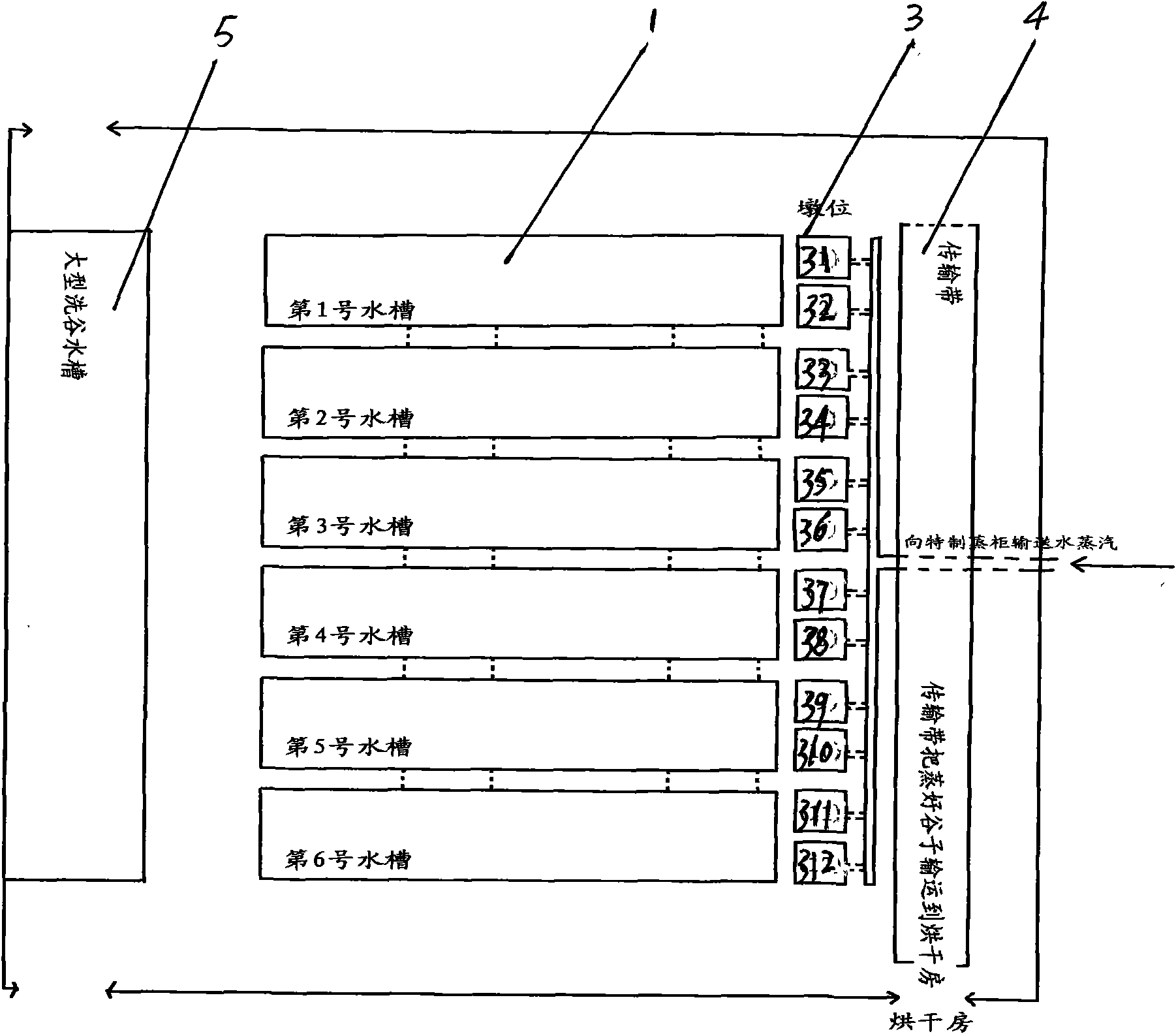

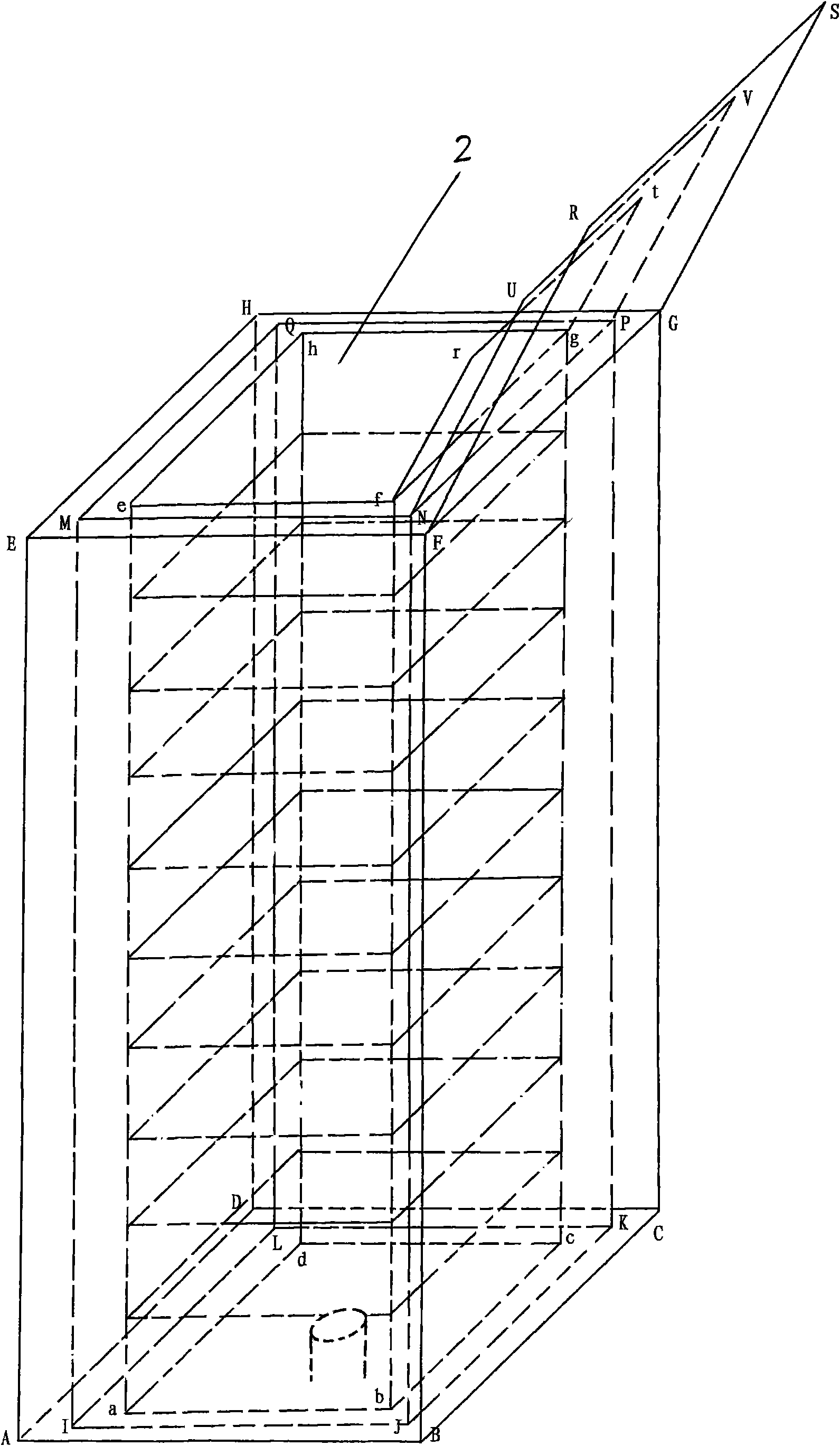

[0024] The structure diagram of the present invention is as figure 1 , 2 Shown, the production equipment of healthy rice of the present invention, the production equipment of healthy rice of the present invention, comprises the steam rack that can pack into steam box, some porridge troughs 1, some piers 3 that are equipped with steam cabinet 2, can hang The steaming rack out of the steaming cabinet 2 is transported to the conveyor belt 4 and the rice milling machine for processing in the drying room, wherein the cleaned and screened rice is loaded into the steaming box of the steaming rack, and the steaming racks loaded with rice are sequentially put into the soaked rice Soak the grains in the water tank 1 and put them into the steaming cabinet 2 to steam the grains. The conveyor belt 4 transports the steamed grains to the drying room for drying treatment. After the drying process, the steamed grains are milled by a rice mill rice.

[0025] The quantitative relationship betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com