Manufacturing method of high-density heat dissipating device with multiple heat dissipating fins

A manufacturing method and technology of a heat dissipation device, which are applied in the directions of manufacturing tools, casting molding equipment, casting molds, etc., can solve problems such as being less than ideal, affecting heat conduction efficiency, and failing to conduct heat dissipation fins smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to further explain the technical means and effects that the present invention adopts to achieve the intended invention purpose, the following in conjunction with the accompanying drawings and preferred embodiments, the manufacturing method of the high-density heat dissipation device with high multiple heat dissipation fins proposed according to the present invention Specific embodiments, structures, features and effects thereof are described in detail below. For convenience of description, in the following embodiments, the same elements are denoted by the same numbers.

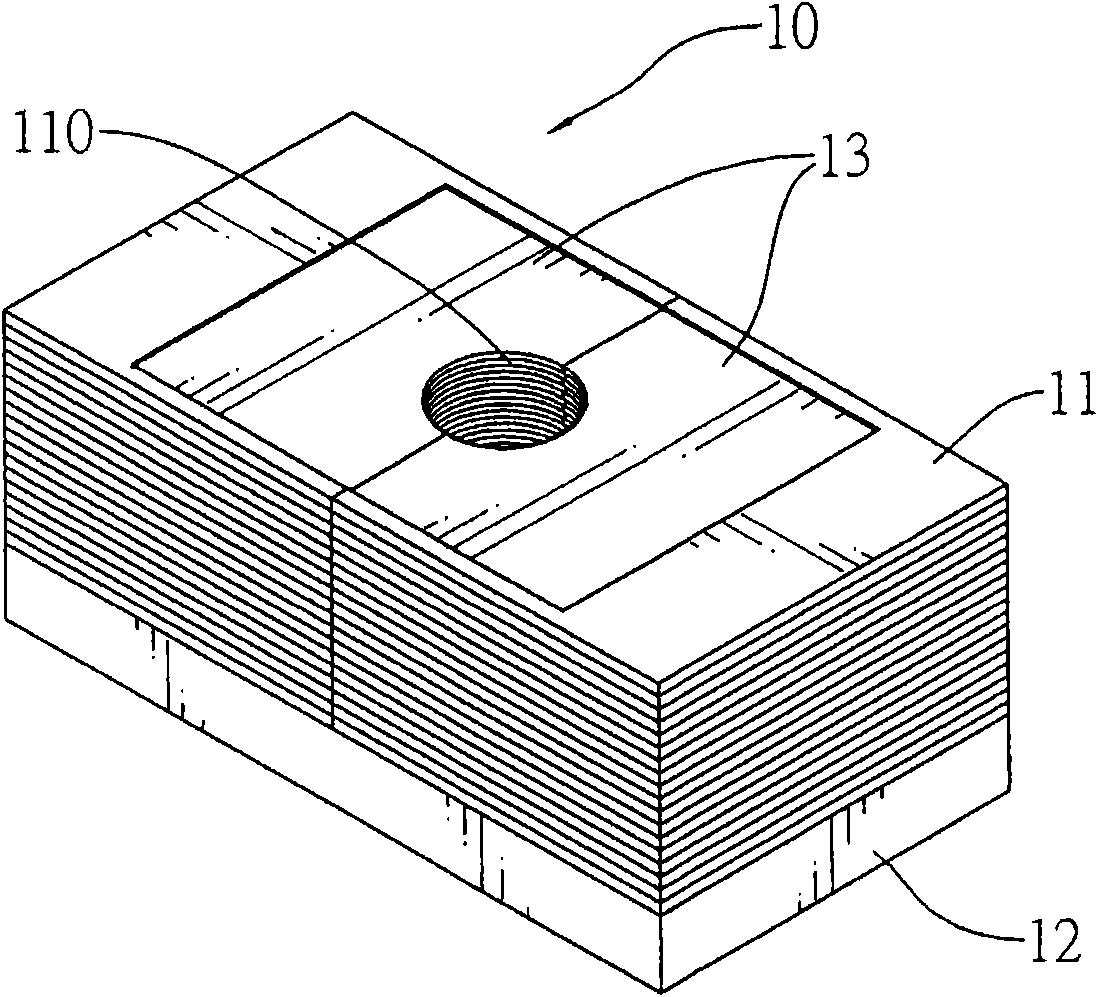

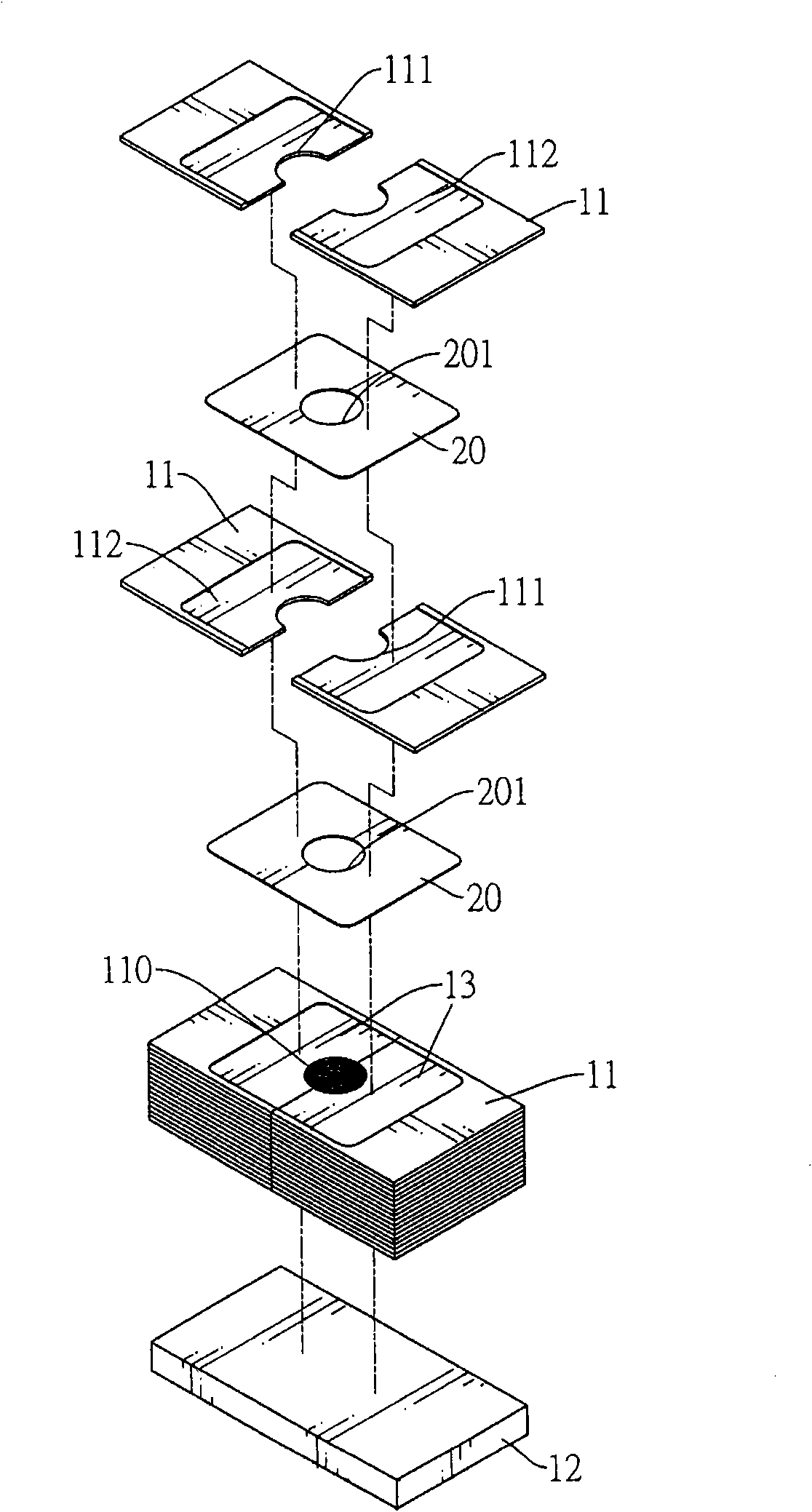

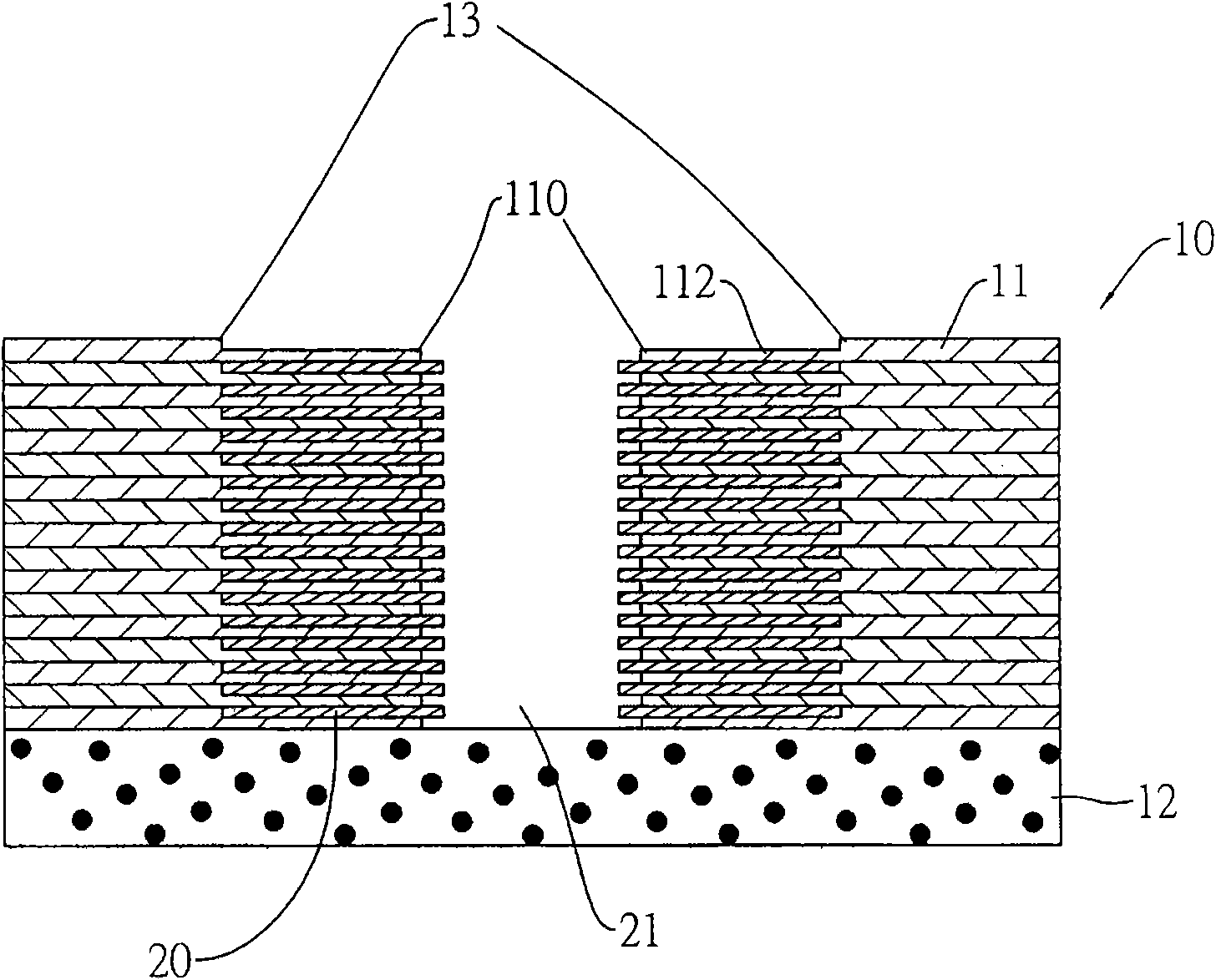

[0063] see Figure 1 to Figure 4 , which discloses a first embodiment of the present invention, that is, a diagram of an embodiment of a high-density heat dissipation device for producing lateral high-multiple heat dissipation fins.

[0064] Please refer to figure 1 As shown, the mold 10 used in this embodiment is composed of a bottom block 12, a plurality of corresponding and stacked dies 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com