Hazel endothelin and extracting method and drug application thereof

A hazelin, the name of the technology, applied in the field of application in the preparation of drugs for the treatment of hyperlipidemia, to achieve a significant effect of curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

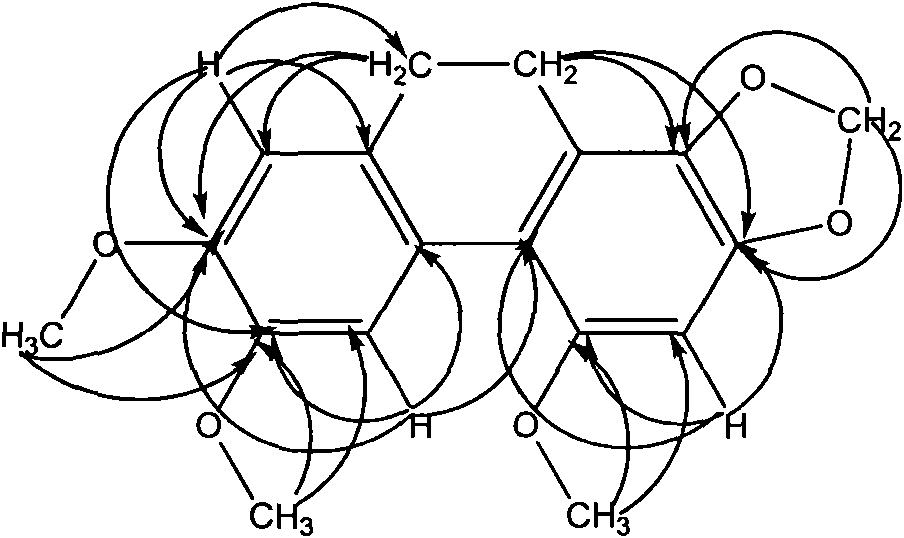

Method used

Image

Examples

Embodiment 1

[0032] a. Extraction: Take 5.0kg of dried hazel leaves, soak them with 3 times the amount of 85% ethanol at room temperature for 24 hours, filter, recover the solvent, extract 3 times, combine the extracts, recover the solvent under reduced pressure to a relative density of 1.12, and filter , the filtrate was extracted with petroleum ether, chloroform, ethyl acetate and n-butanol successively, and the solvent was recovered under reduced pressure to dryness to obtain 25 g of n-butanol.

[0033] b. Separation: The obtained n-butanol part is subjected to silica gel column chromatography of 200-300 meshes, eluted with chloroform-methanol 1:1, the eluate is collected, and the solvent is recovered to obtain the crude hazelin A product with a yield of 0.012%. ,

[0034] c. Purification of hazelin A: the crude hazelin A was recrystallized with methanol to obtain pure hazelin A: 0.6 g.

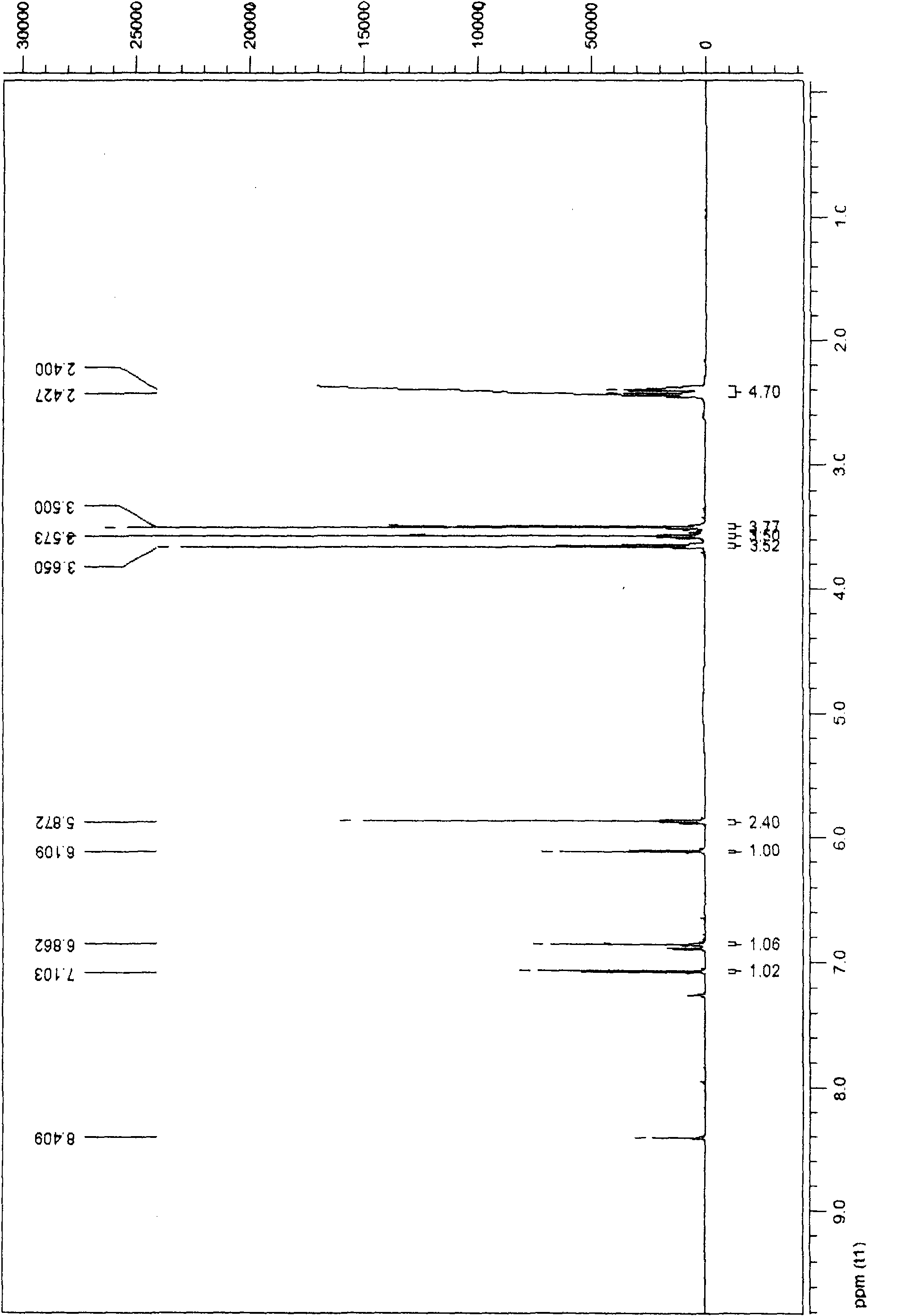

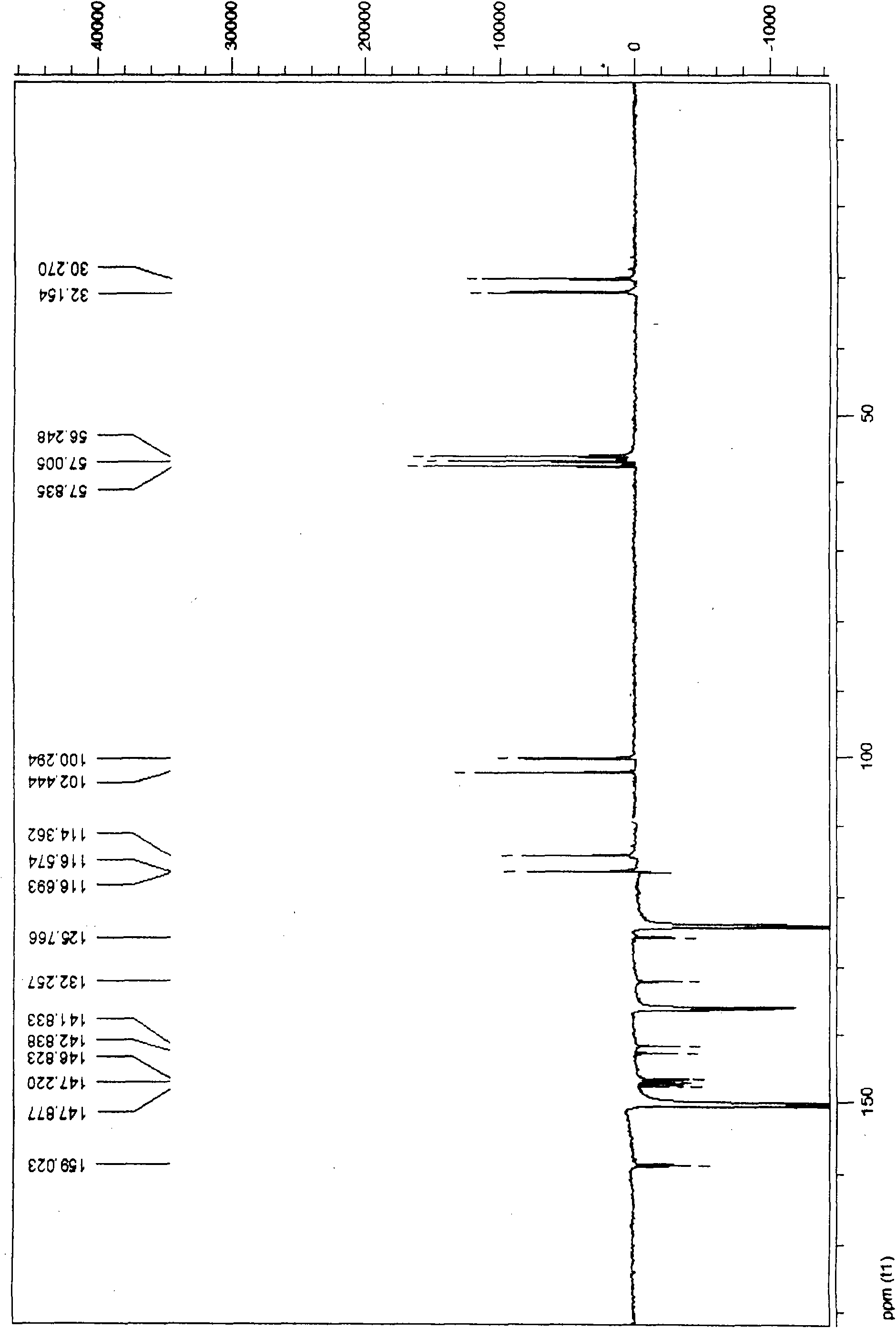

[0035] Identification: Spectroscopy method was used for structural identification.

[0036] HR-ES...

Embodiment 2

[0050] a. Extraction: Take 5.0kg of dried hazel leaves, soak them with 4 times the amount of 75% ethanol at room temperature for 24 hours, filter, recover the solvent, extract 3 times, combine the extracts, recover the solvent under reduced pressure to a relative density of 1.15, and filter , The filtrate was sequentially extracted with petroleum ether, chloroform, ethyl acetate, and n-butanol, and the solvent was recovered under reduced pressure to dryness to obtain 28 g of n-butanol.

[0051] b. Separation: The obtained n-butanol part is subjected to silica gel column chromatography of 200 to 300 meshes, eluted with chloroform-methanol 1:5, the eluate of part A of hazelin is collected, and the solvent is recovered to obtain a crude product of hazelin A. Yield 0.013%.

[0052] c. Purification of hazelin A: the crude hazelin A was recrystallized with methanol to obtain pure hazelin A: 0.64 g.

Embodiment 3

[0054] a. Extraction: Take 5.0kg of dried hazel leaves, soak them in 5 times the amount of 95% ethanol at room temperature for 24 hours, filter, recover the solvent, extract 3 times, combine the extracts, recover the solvent under reduced pressure to a relative density of 1.14, and filter , the filtrate was sequentially extracted with petroleum ether, chloroform, ethyl acetate, and n-butanol, and the solvent was recovered under reduced pressure to dryness to obtain 30 g of n-butanol.

[0055] b. Separation: the obtained n-butanol part is subjected to silica gel column chromatography of 200 to 300 meshes, eluted with chloroform-methanol at 1:10, the eluate of hazelin A part is collected, and the solvent is recovered to obtain hazelin A crude product, Yield 0.015%.

[0056] c. Purification of hazelin A: take crude hazelin A and recrystallize it with methanol to obtain pure hazelin A: 0.7 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com