Production system of thermosetting powder coating

A thermosetting powder and production system technology, applied in powder coatings and other directions, can solve the problems of sheet-pressed sheet sticking to rollers, unable to meet the production requirements of thermosetting powder coatings, waste of water resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

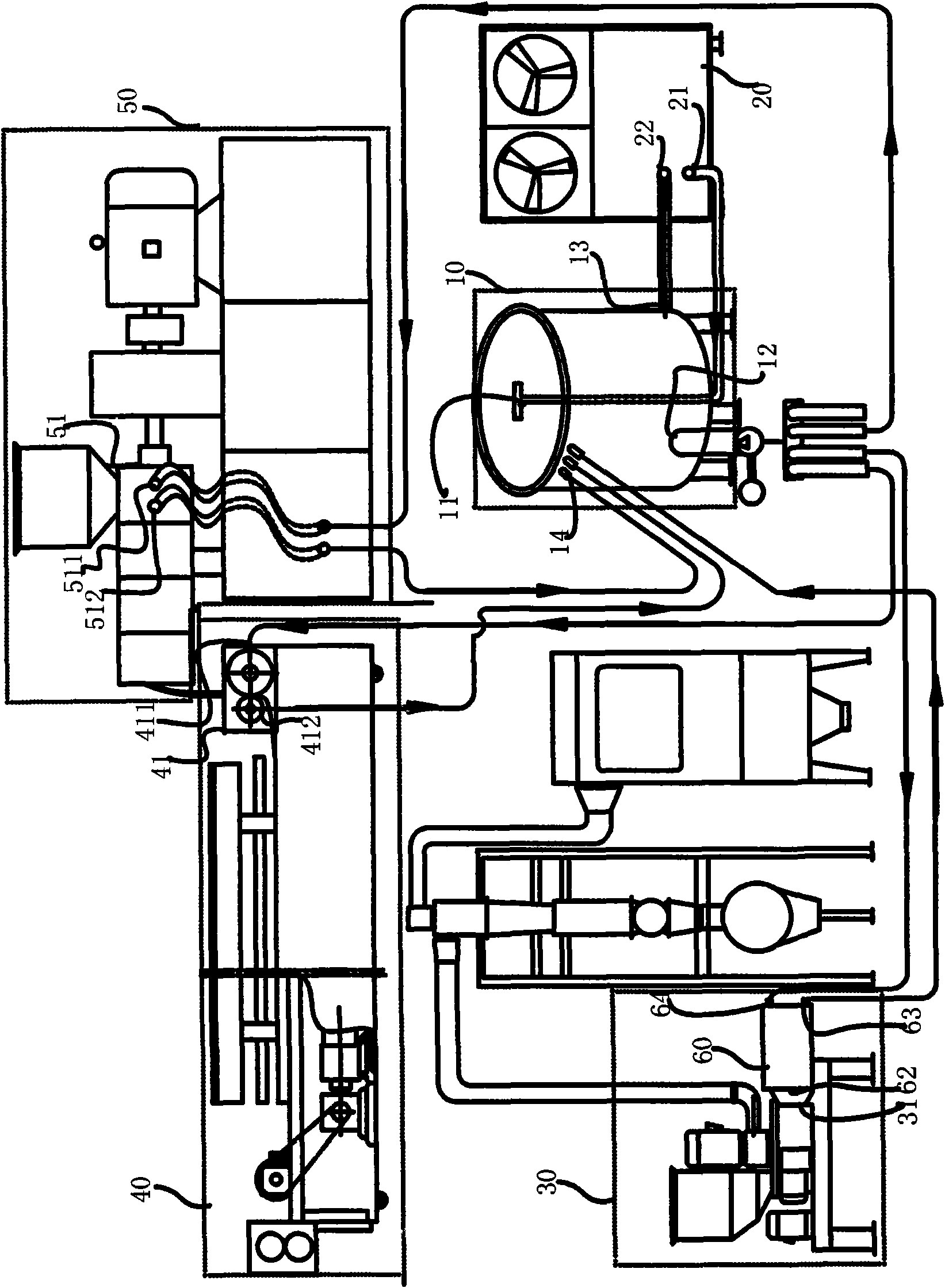

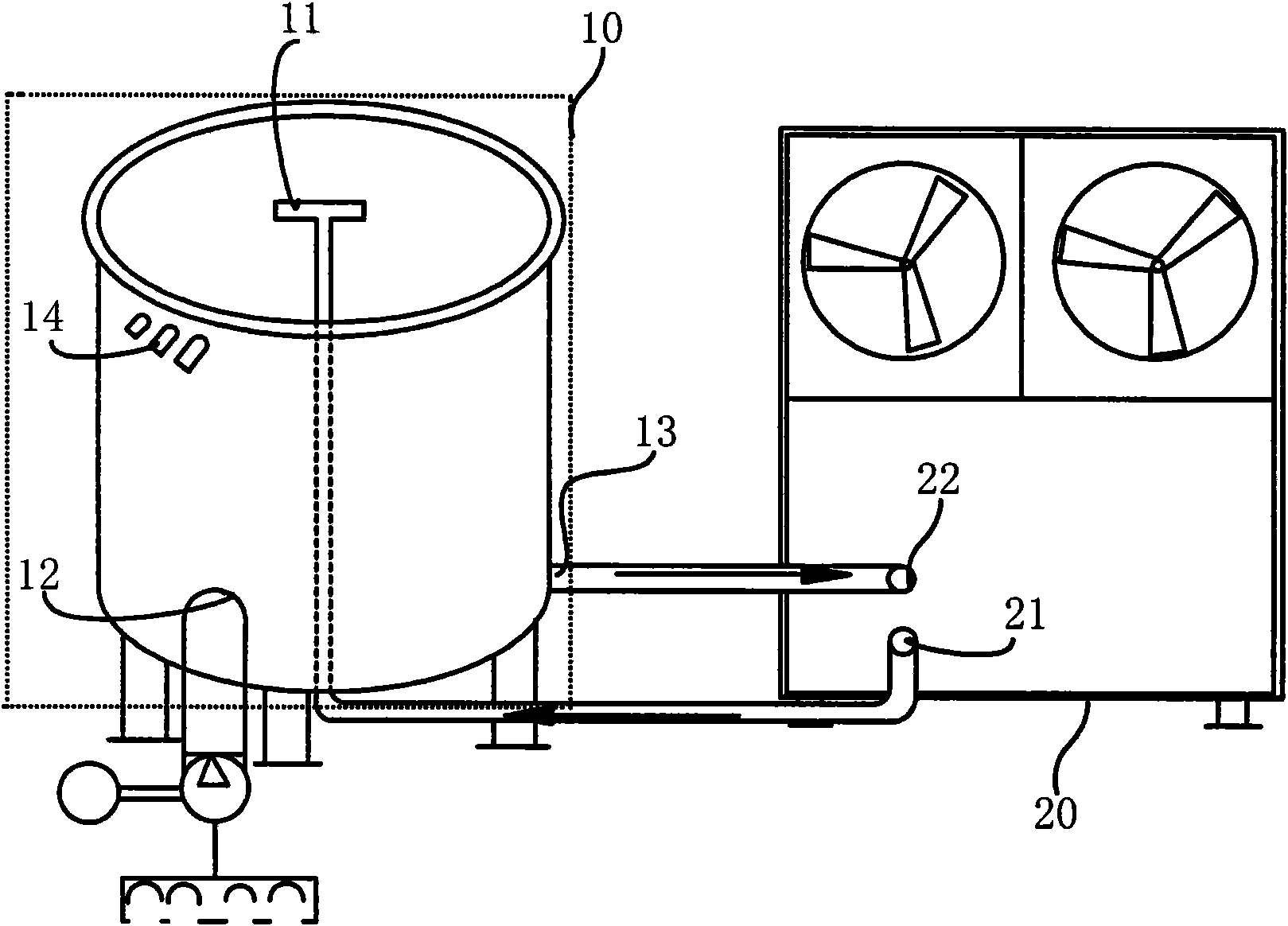

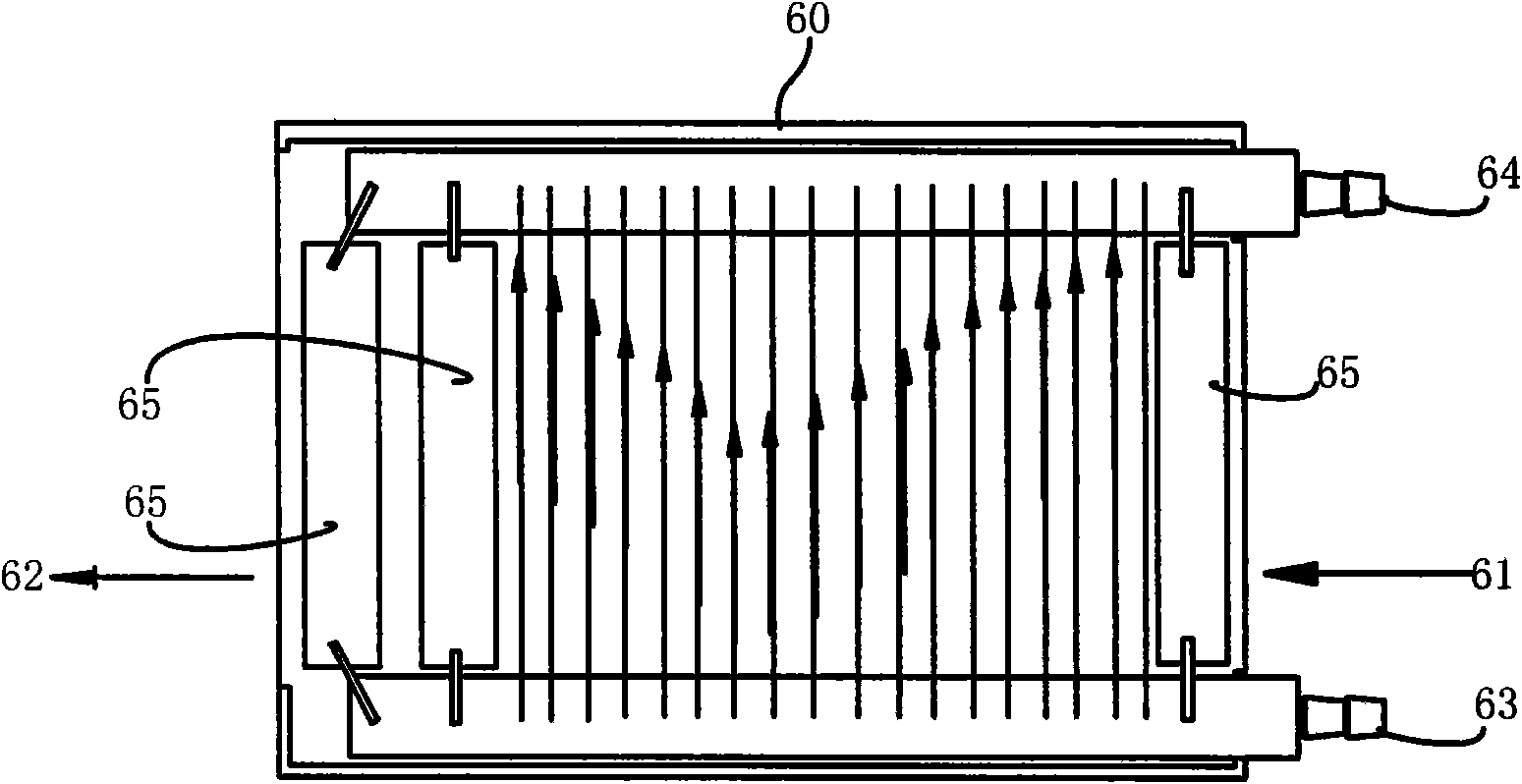

[0012] Such as Figure 1-6 Shown, a kind of production system of thermosetting powder coating comprises mixer, pulverizer 30, tablet press 40, extruder 50, described pulverizer 30, tablet press 40 and extruder 50 and cooling The water circulation system is connected, and the cooling water circulation system is divided into three routes, one of which is that the cooling water circulation system is connected with the water pipeline of the heat exchanger 60 arranged at the air inlet 31 of the pulverizer 30, and the air outlet of the heat exchanger 60 62 is connected with the air inlet 31 of the mill 30, the cooling water outlet 12 of the water storage device 10 is connected with the water inlet 64 of the water pipe of the heat exchanger 60, and the second is that the cooling water circulation system is connected with the tablet press 40, and the storage The cooling water outlet 12 of the water device 10 is connected with the water inlet 411 of the tablet roller 41 of the tablet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com