Method for selective hydrogenation and separation for pyrolysis gas

A technology for selective hydrogenation and cracking of gas, which is applied in the field of selective hydrogenation of alkynes and dienes, which can solve the problems of limited hydrogen, increased energy consumption, and reduced activity of polymerization catalysts, so as to improve selectivity and safety and reduce energy consumption. consumption and equipment size, and the effect of reducing the number of reaction devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

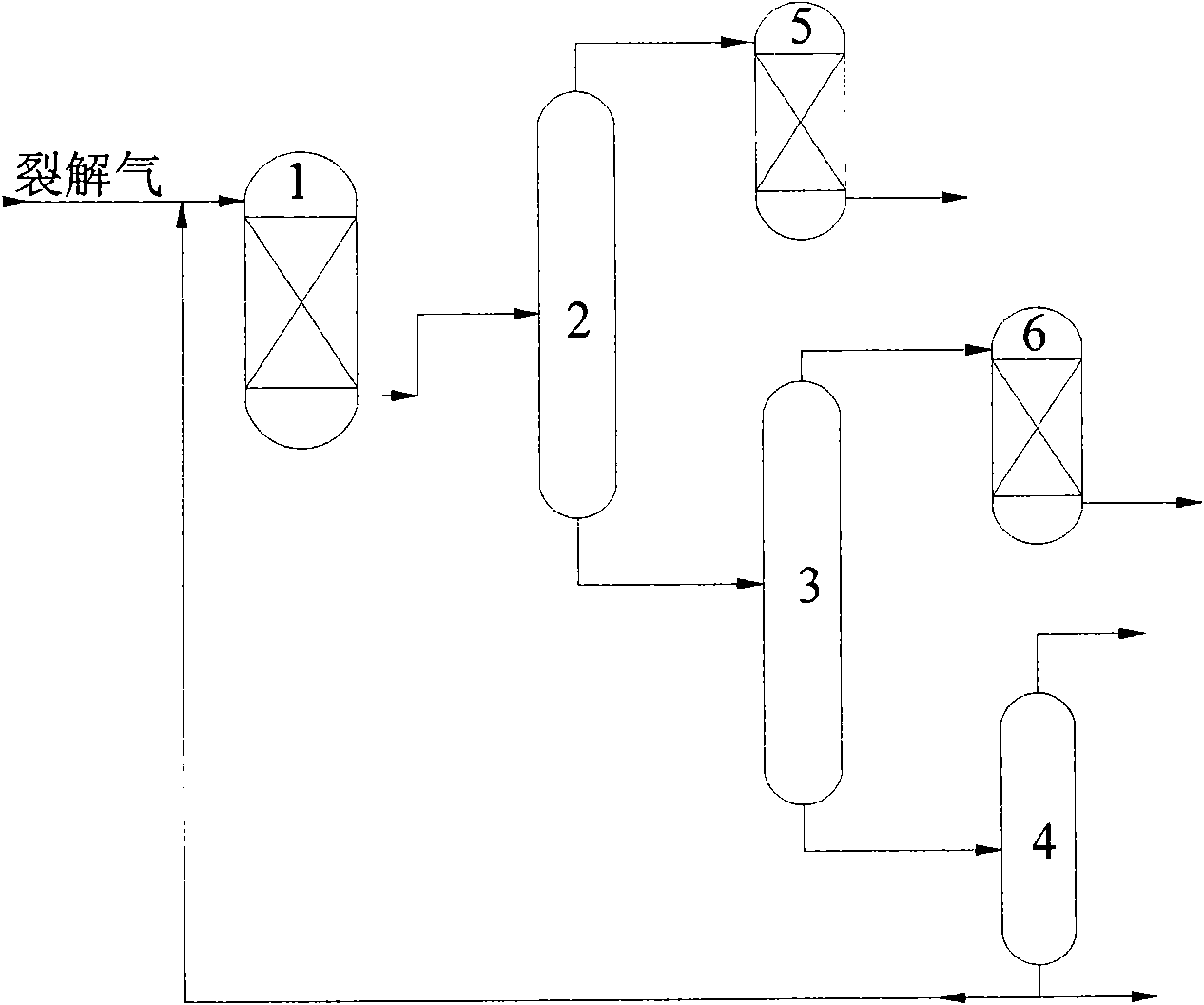

[0064] see figure 1, the gas phase raw material 1 containing olefins obtained from the steam cracking unit, the specific composition can refer to Table 1, mixed with the liquid phase flow from the bottom of the debutanizer, and then heat exchanged in the heat exchanger, enter the mixed phase Hydrogenation Reactor 1. Mixed-phase hydrogenation reactor 1 uses BC-L-83A hydrogenation catalyst (Sinopec Produced by the company Beijing Research Institute of Chemical Industry) to operate in the presence of most of the acetylene hydrogenation, such as the remaining 100ppm (mole) of acetylene, which means that the conversion rate of propyne and propadiene is about 50%, and the conversion of carbon four or more dienes The rate is about 80%. The reaction product from the mixed-phase hydrogenation reactor is cooled by a cooler and enters the front deethanizer 2, where it is separated into a liquid phase flow and a gas phase flow, and the gas phase flow enters the carbon two front hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com