Method for measuring arsenic in gas and dust discharged by roasting and burning furnace

A determination method and incinerator technology, which are applied in the preparation of test samples and the measurement of color/spectral properties, etc., can solve problems such as analysis effects, and achieve the effects of simple operation, good popularization and application value, and strong anti-interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

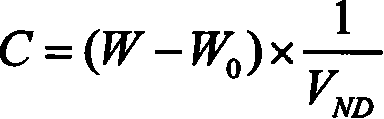

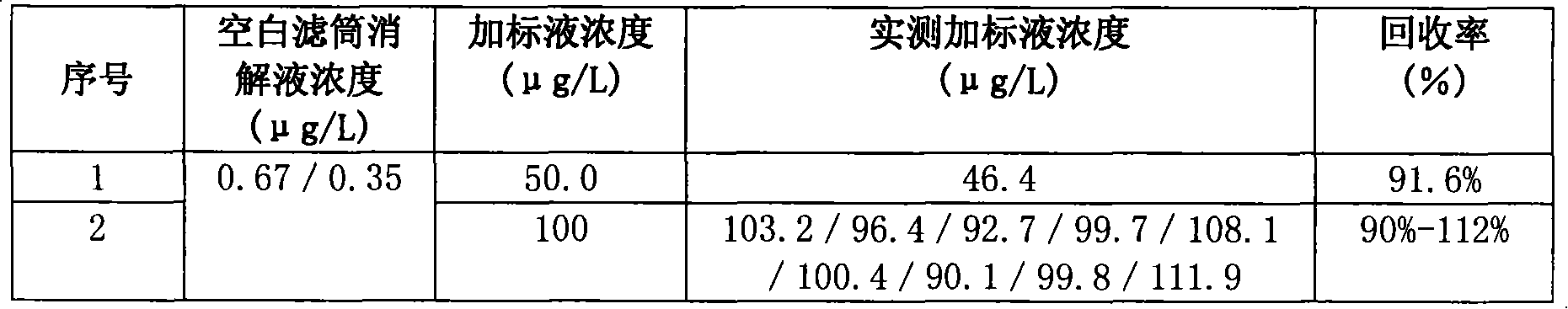

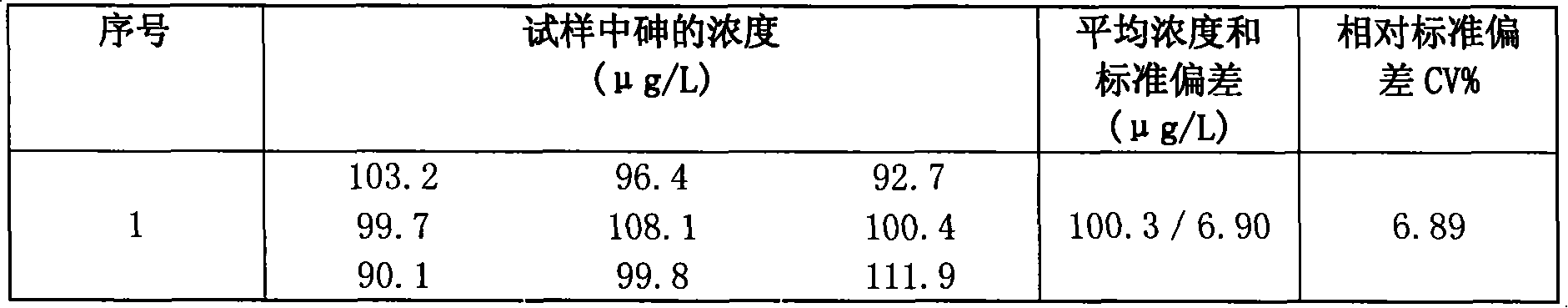

Method used

Image

Examples

Embodiment Construction

[0019] First, a corundum filter cartridge with a specification of 28mm*100mm (outer diameter*length) and a wall thickness of 1.5mm is used to pre-digest it with mixed acid. Put the corundum filter cartridge in a beaker, add (1+1) 7ml of sulfuric acid, 20ml of nitric acid, and 4ml of perchloric acid, and heat it on an electric plate. After the violent reaction stops, heat it until thick white smoke of perchloric acid is emitted. Take it off and let it cool, rinse the wall of the bottle with water, and then heat until thick white smoke is emitted to drive away the nitric acid. Add a small amount of water and continue to heat and boil. After cooling, take out the corundum filter cartridge, wash it with water several times, dry it and use it to collect gas and dust samples from roasting incinerators.

[0020] After the sample is collected, put the corundum filter cartridge together with the gas dust sample in a beaker, add (1+1) 7ml of sulfuric acid, 20ml of nitric acid, and 4ml o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com