Edible fungus culturing equipment

A cultivation equipment and edible fungus technology, applied in botany equipment and methods, applications, horticulture, etc., can solve the problems of uneven distribution of inoculated bacteria, incomplete disinfection of bacterial materials, and insufficient utilization of bacterial materials, etc., to reduce miscellaneous The effect of reducing the chance of bacterial infection, reducing inoculation procedures, and shortening the time for germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

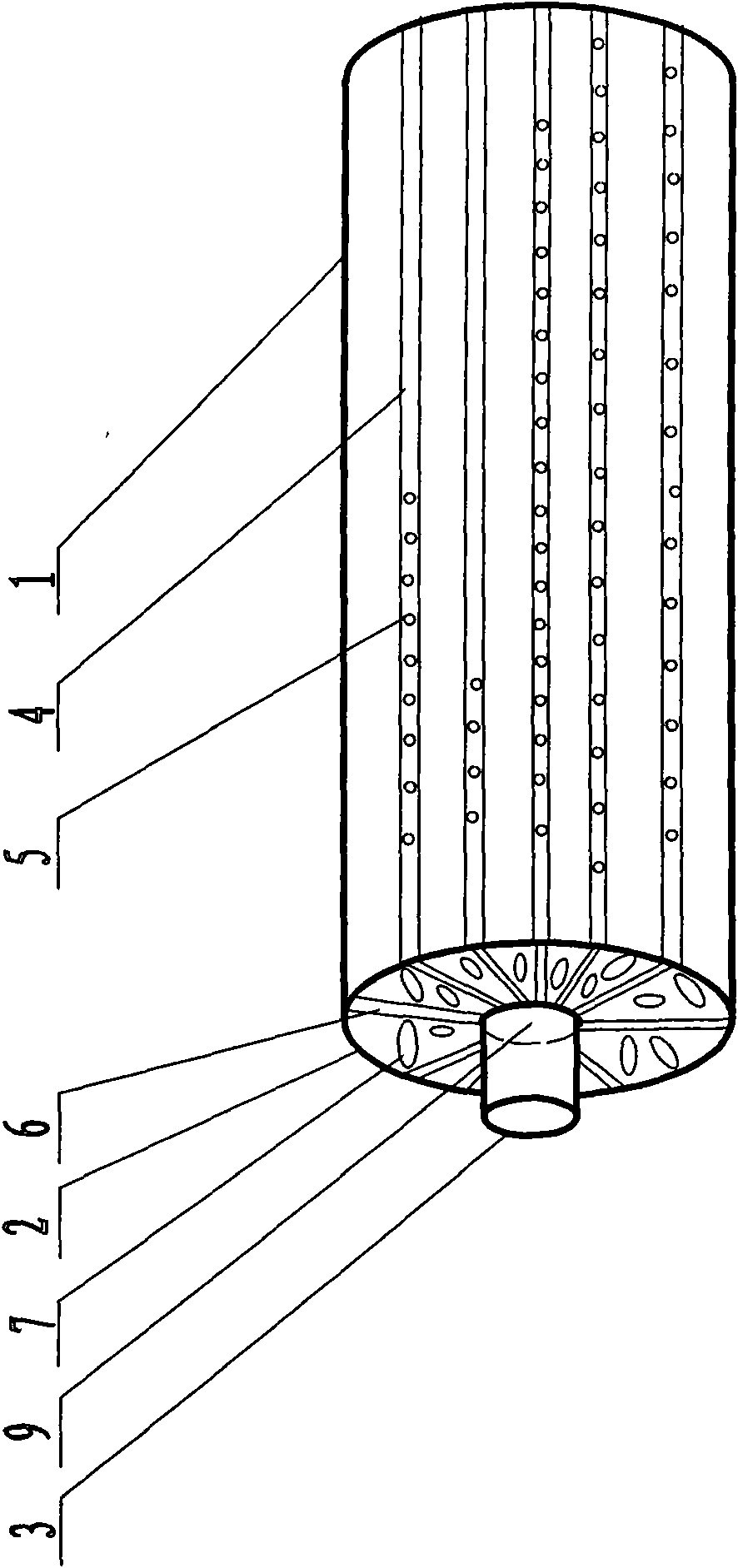

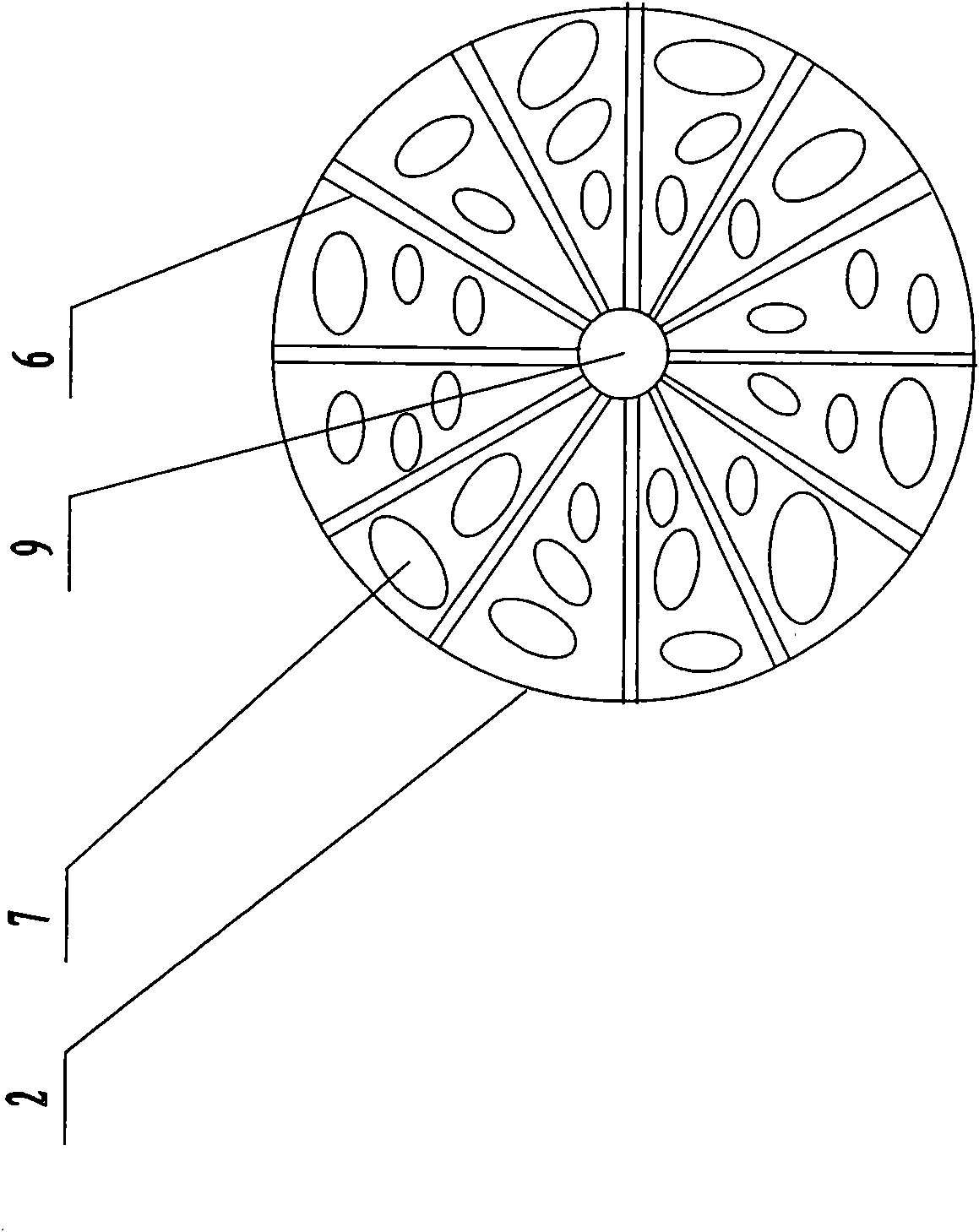

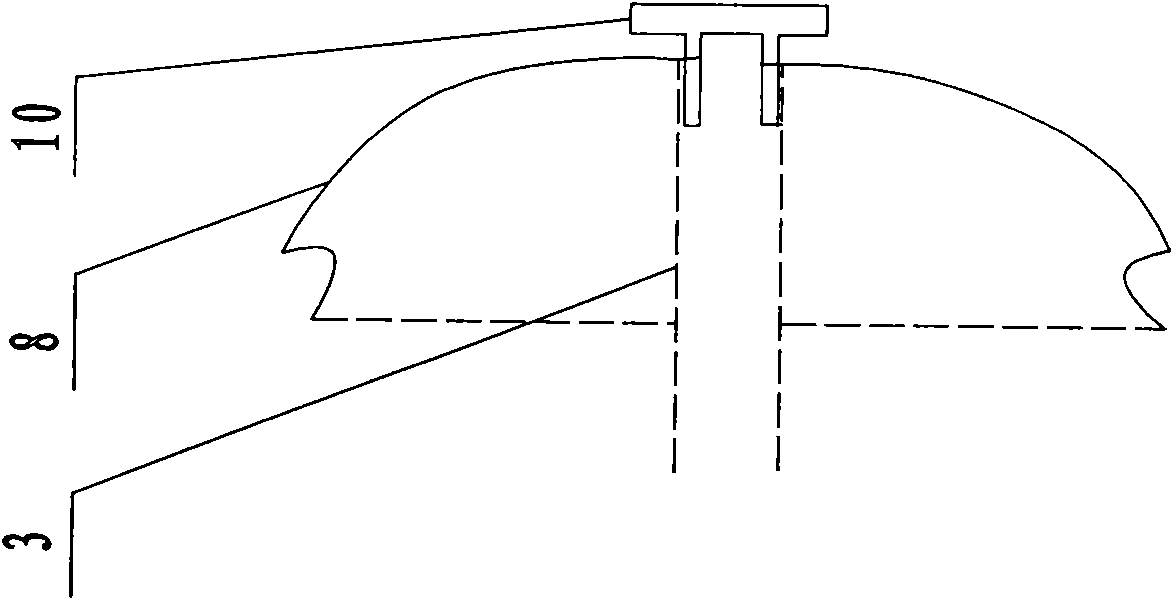

[0014] The edible mushroom cultivation equipment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] With reference to the accompanying drawings, the edible fungus cultivation equipment of the present invention includes a bacterium 1, and several screen tubes 4 are distributed on the periphery of the bacterium, and one or two rows of sieve holes are evenly distributed in the axial direction on the body of the sieve tube 4. 5. There is a detachable partition 2 at both ends of the bacterium 1, and a ventilation hole 7 is formed on the partition. There is a central hole 9 in the center of the partition 2, and the two ends of the central screen 3 are placed in the central hole 9. There are sealing covers on the two ports of the central screen 3, and the central screen 3 is installed along the axis of the shaft. There are two to four rows of screen holes and connection holes are also made at the two ports. 8-12 connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com