Preparation method of sub-micron zinc powder and preparation device thereof

A submicron and submicron-level technology, applied in the field of submicron zinc powder preparation, can solve the problems of difficult equipment processing, inability to achieve continuous operation, and huge investment in equipment, so as to save non-ferrous metal resources and facilitate precise adjustment and control , The effect of broadening the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

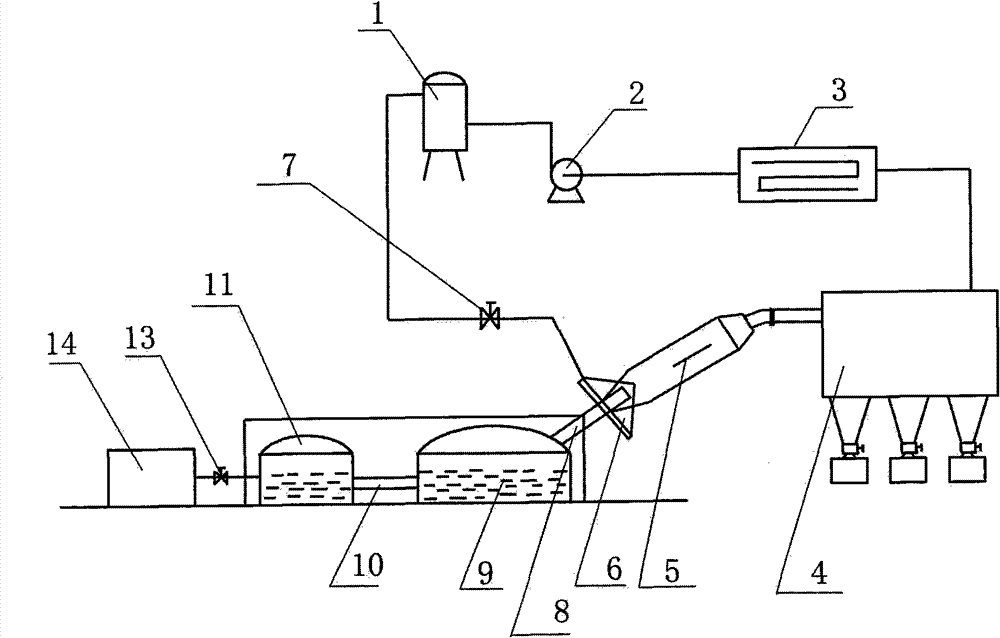

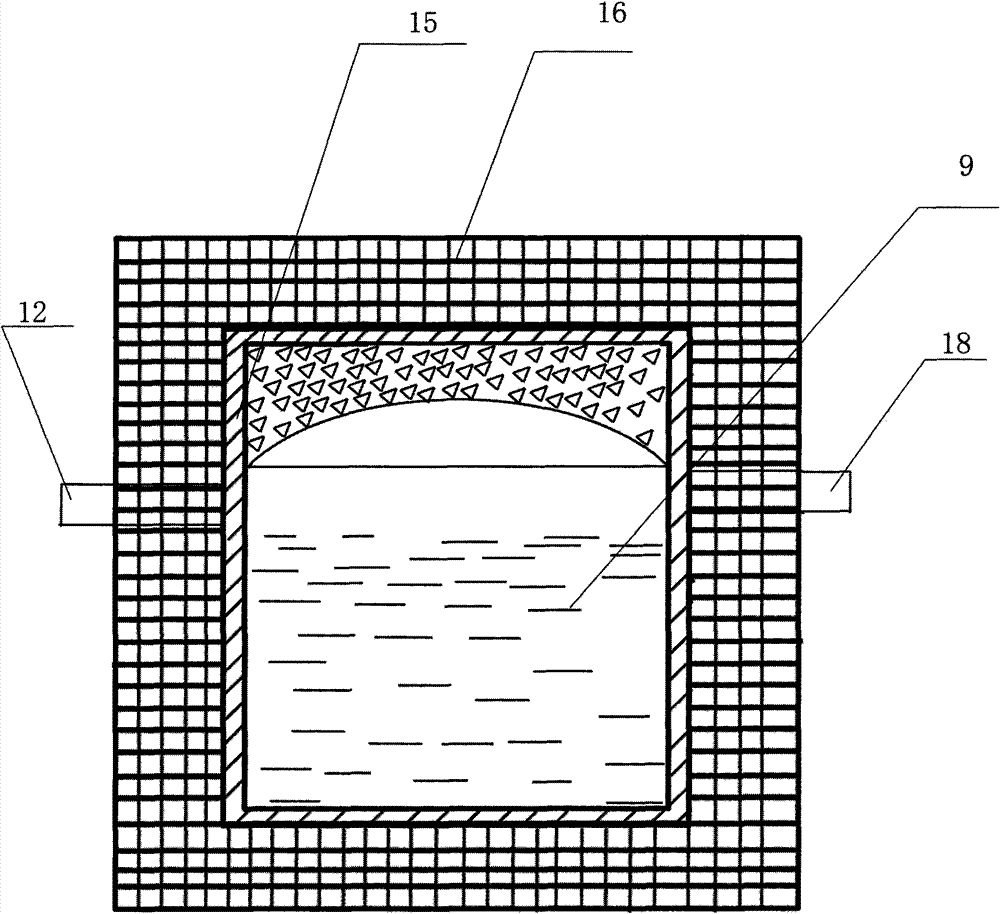

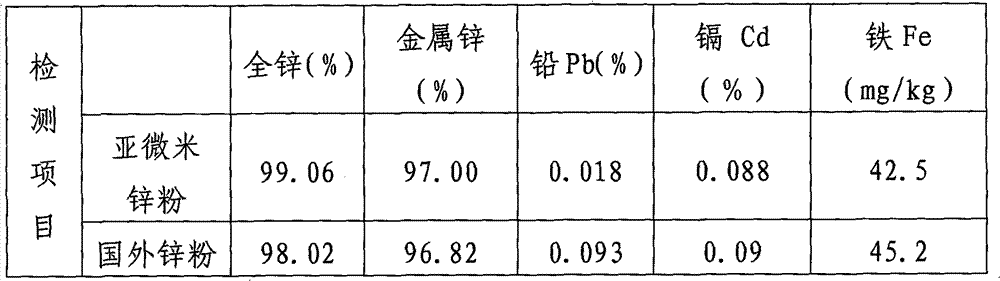

[0022] The present invention discloses a method for preparing submicron zinc powder and a preparation device thereof. It includes the following steps: Step 1, firstly, put the No. 1 zinc ingot into the melting furnace 11 in the melting furnace 11 at 420°C Under the conditions of heating and melting, the zinc ingot is added several times according to the needs, and the addition amount is 400-600Kg / 8h each time, and then the zinc liquid with high zinc content is melted out at a constant temperature while maintaining the heating temperature; step two , And then the zinc liquid is continuously and uniformly flowed into the closed evaporation pool 9 for evaporation, and the evaporation temperature is greater than or equal to 907 ℃ to form zinc vapor; step three, the zinc vapor is introduced into the condenser 5 through the air duct, and the temperature in the condenser The temperature is 220-300°C, and then the supersonic inert air stream sprayed into the condenser 5 through the Lava...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com