Application method of compound tungstate corrosion inhibitor of sea water

An application method, tungstate technology, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc., can solve the problems of high corrosion inhibitor use cost, low production cost, and corrosion inhibition efficiency Low and other problems, to achieve the effect of low production cost, low cost and high corrosion inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

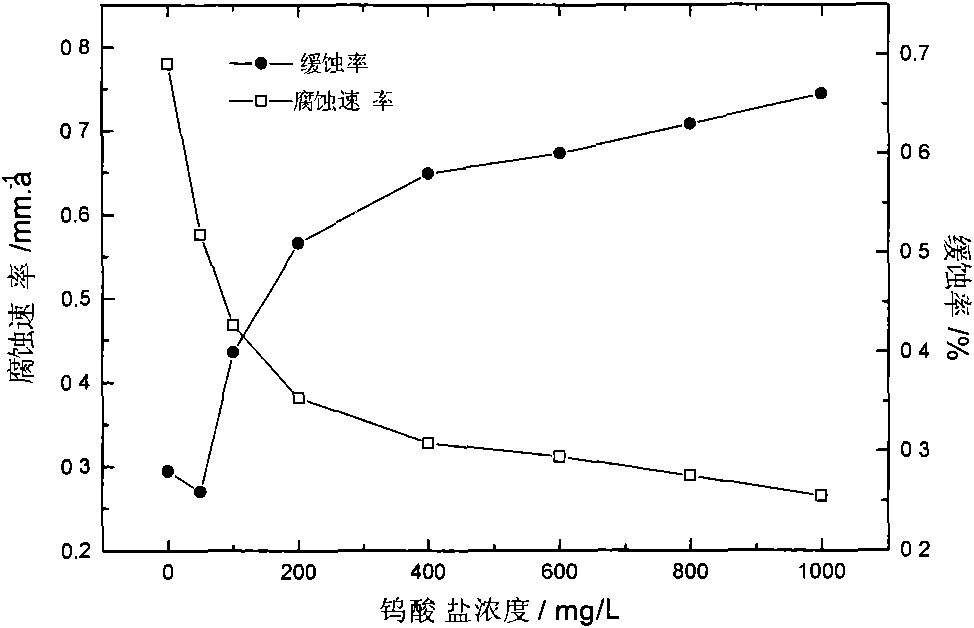

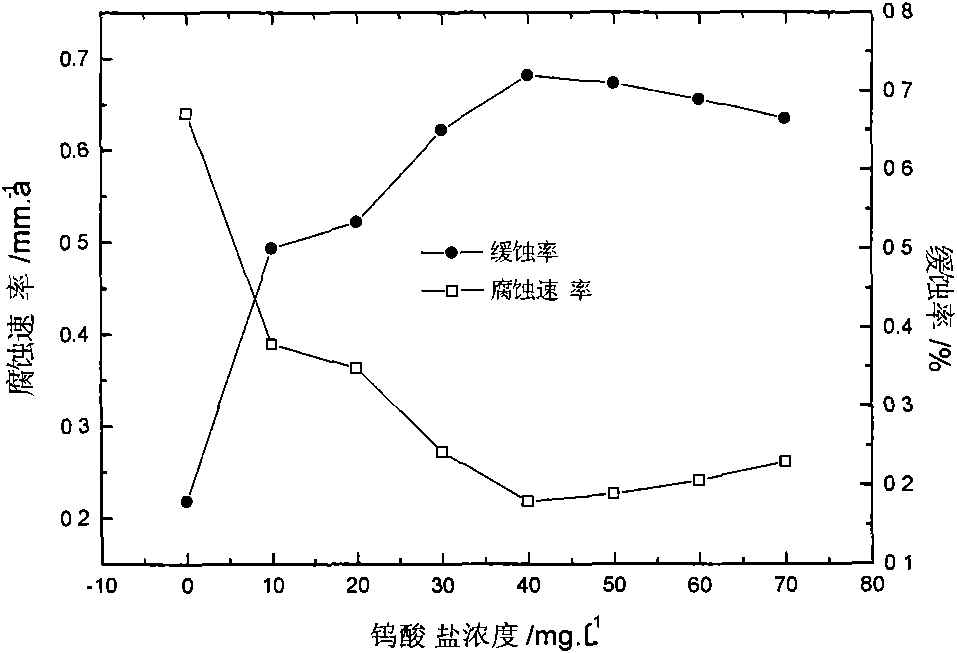

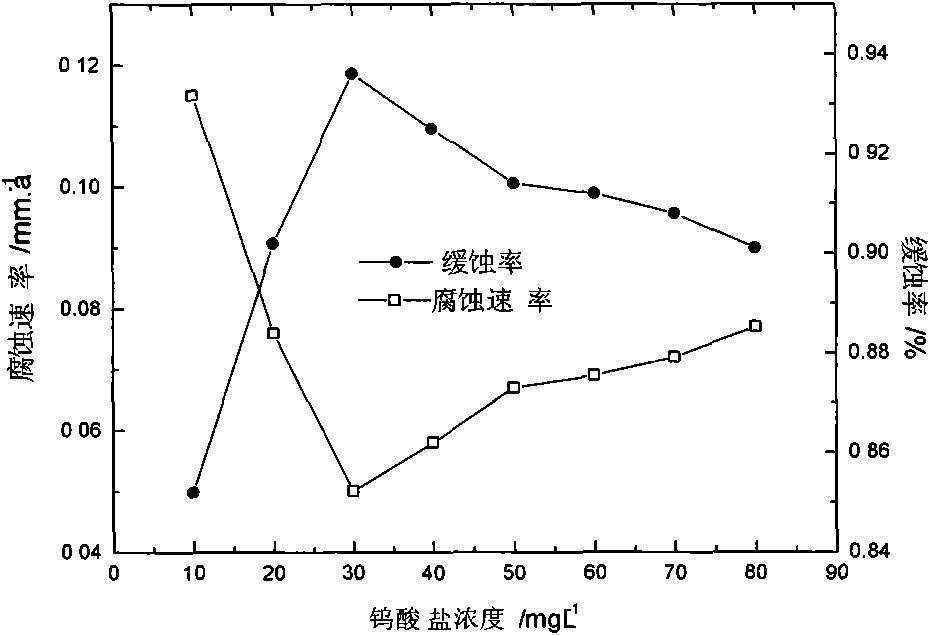

Image

Examples

Embodiment 1

[0012] Embodiment 1: In 1 liter of seawater, according to the mass concentration ratio, respectively take tungstate 40mg / L, polyepoxysuccinic acid 40mg / L, sodium gluconate 40mg / L and Zn 2+ (Zinc salt) 4mg / L is sequentially added to the circulating and cooled seawater, at a temperature of 30°C and within the range of adjusting the pH value to 6.5, it will have good corrosion inhibition.

[0013] Application Method Example 2: Based on 1 liter of seawater, 40 mg / L of tungstate, 40 mg / L of polyepoxysuccinic acid, 40 mg / L of sodium gluconate and Zn 2+ (Zinc salt) 4mg / L is sequentially added to the circulating and cooled seawater, and the temperature is 50°C, and the pH value is adjusted within the range of 8.0, it will play a very good corrosion inhibition.

[0014] Application Method Example 3: Based on 1 liter of seawater, tungstate 40mg / L, polyepoxysuccinic acid 40mg / L, sodium gluconate 40mg / L and Zn 2+ (Zinc salt) 4mg / L is sequentially added to the circulating and cooled seawa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com