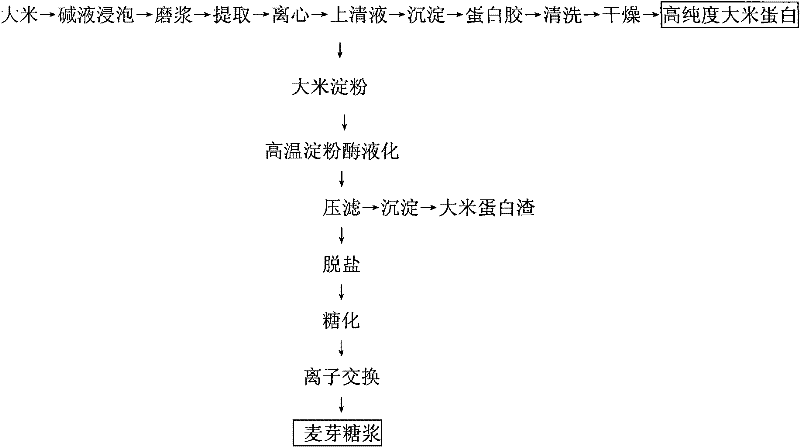

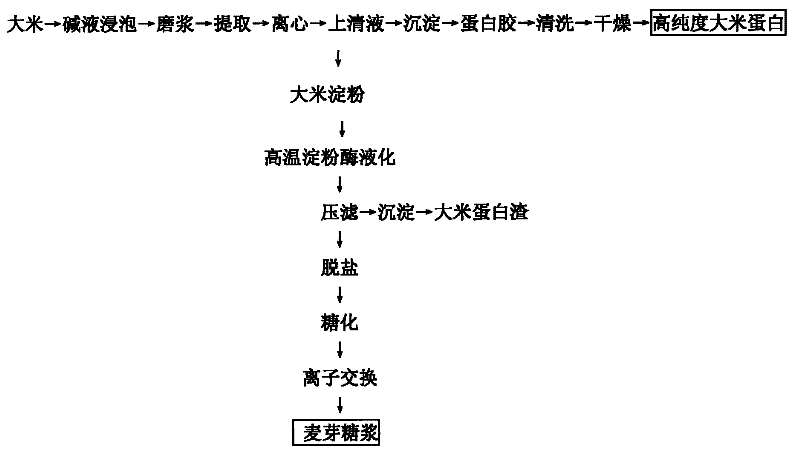

Method for co-producing high-purity rice protein and malt syrup by rice

A technology of rice protein and maltose syrup, applied in the direction of fermentation, etc., can solve the problems of waste of raw materials, long production time, serious energy consumption, etc., and achieve the effect of reducing preparation time, reducing dosage, and shortening liquefaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Wash 1000 grams of rice, soak in 5 liters of 0.05mol / L sodium hydroxide solution for 0.5 hours, refine the pulp, stir and extract at 25°C for 2 hours, centrifuge to obtain the supernatant and rice starch, and adjust the pH of the supernatant to 6.5, centrifuge to get the protein glue, wash and spray dry to obtain rice protein with a protein content of 85%. The rice starch is cleaned, the ratio of material to liquid is 1:3 (w / v), and the mass fraction is 0.01% of liquefying enzyme, which is liquefied at 95-105 degrees for 20-40 minutes, press-filtered, desalted by membrane filtration, and the filtrate is saccharified Enzymatic saccharification, activated carbon decolorization, and finally ion exchange to obtain maltose syrup.

Embodiment 2

[0013] Wash 5000 grams of rice, soak in 45 liters of 0.09mol / L sodium hydroxide solution for 15 minutes, refine the pulp, stir and extract at 30°C for 1 hour, centrifuge to obtain the supernatant and rice starch, and adjust the pH of the supernatant to 7. Centrifuge to get protein glue, wash and spray dry to obtain rice protein with protein content of 80%. The rice starch is cleaned, the ratio of material to liquid is 1:3 (w / v), and the mass fraction is 0.1% of liquefying enzyme, which is liquefied at 95-105 degrees for 20-40 minutes, press-filtered, desalted by membrane filtration, and the filtrate is saccharified Enzymatic saccharification, activated carbon decolorization, and finally ion exchange to obtain maltose syrup.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com