Permanent-magnetic hierarchical testing device for content of magnetic substance powder

A testing device and technology for magnetic materials, applied in the direction of magnetic performance measurement, etc., can solve the problems of difficulty in meeting the needs of weak magnetic powder measurement, high equipment footprint and operating costs, and harmful experimental personnel and the environment. The effect of small error, simple measurement and testing process, and easy use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with embodiment (accompanying drawing):

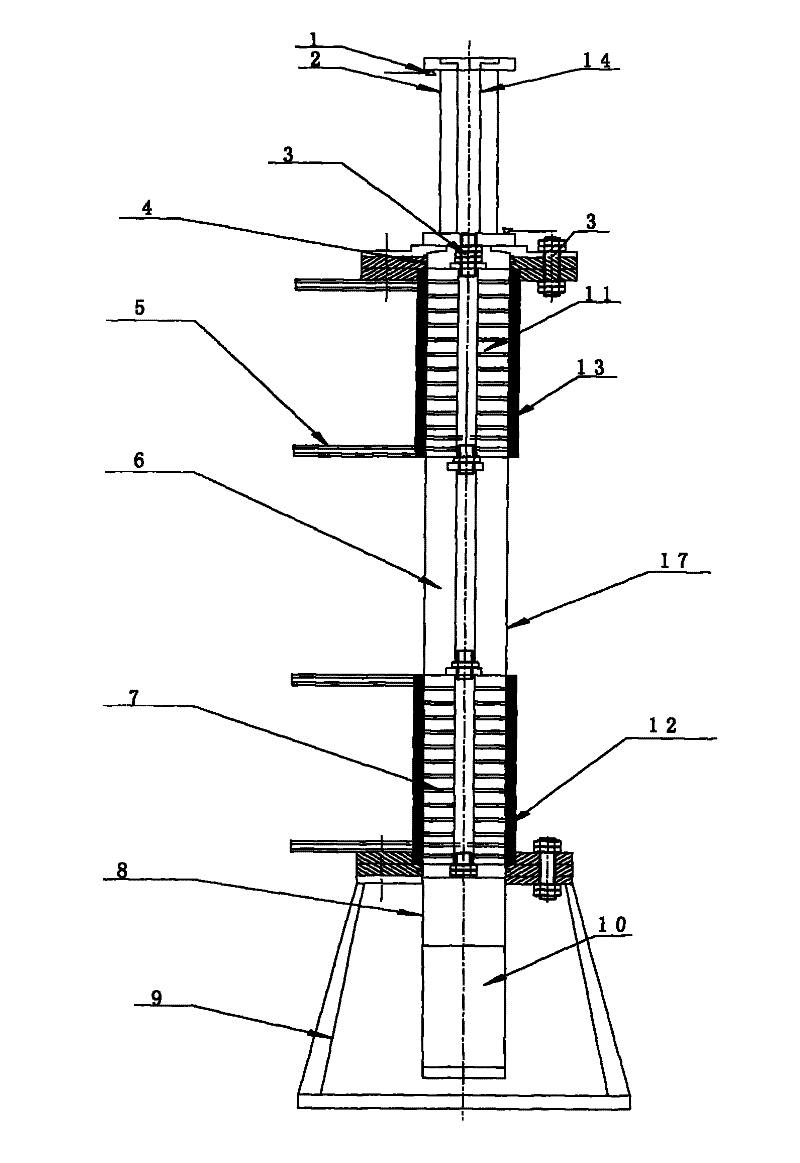

[0039] Such as figure 1 Shown, the powder magnetic matter content permanent magnet ladder test device of the present invention comprises:

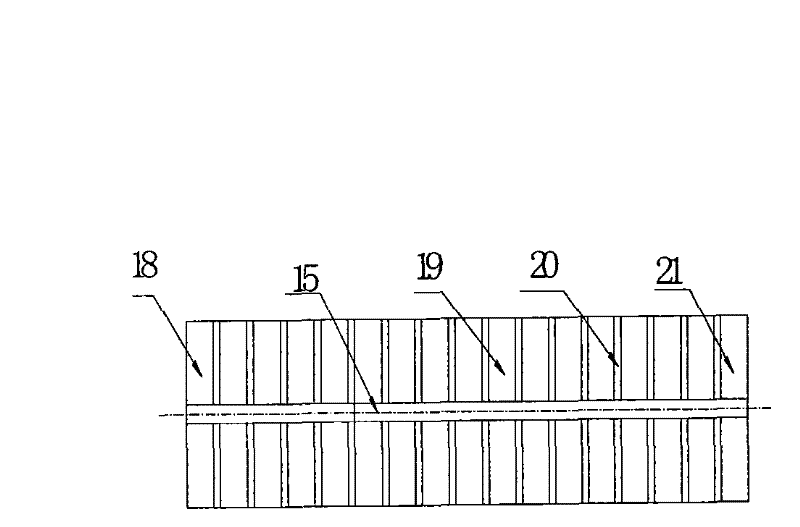

[0040] a. Ferrite magnetic materials, ordinary NdFeB NdFeB magnetic materials and high-performance NdFeB NdFeB magnetic materials are used to make magnetic steels of the same specification and size, and high magnetic permeability is sandwiched between every two adjacent magnetic steels The structure of the yoke piece is constructed by extrusion at least two ladder magnetic sources;

[0041] b. Utilize the annular medium mesh or steel wool magnetic accumulation medium made of high magnetic permeability stainless steel, fill the annular medium mesh or steel wool magnetic accumulation medium in the magnetic accumulation medium filling area (that is, the sorting space), and the magnetic accumulation medium is filled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic susceptibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com