Method for winding transposition wire of double-single spiral coil

A winding method and transposition wire technology, which is applied in coil manufacturing, transformer/inductor coil/winding/connection, etc., can solve the problem of large overlapping thickness of wires, and achieve the effects of reducing hidden dangers, reducing thickness, and increasing filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

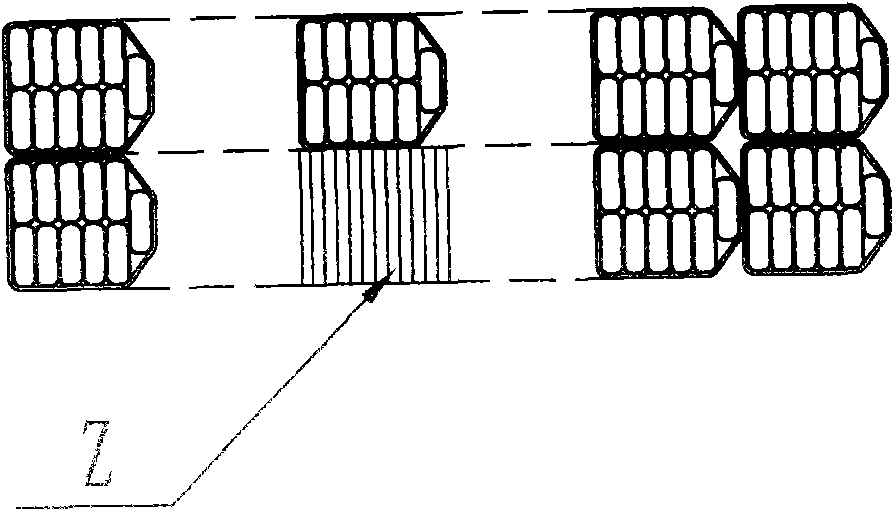

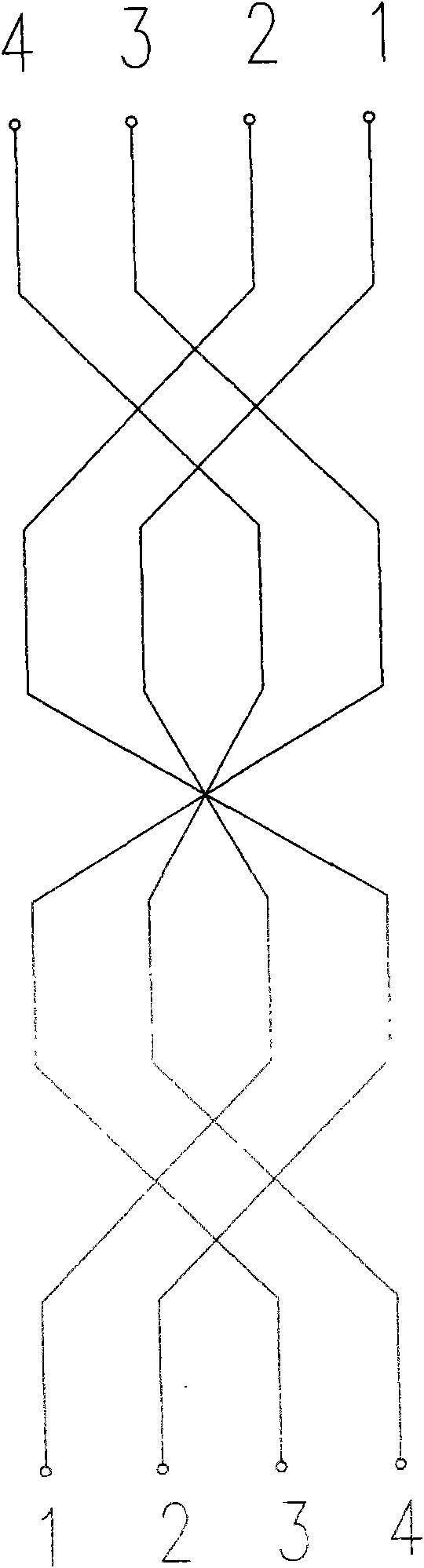

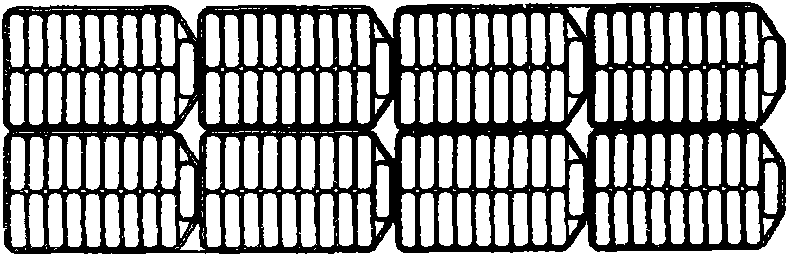

[0018] The winding method of the present invention is: when winding the coil, start winding according to a double helix, that is, two single helix coils are wound simultaneously to form two rows of single helix coils; and each row of wires is grouped (generally, two When the wires of two rows of single helical coils need to be transposed, the wires of two rows of single helical coils are transposed within a group → transposed between groups → transposed within a group → transposed between groups The form is transposed, and an arc pad is placed in the gap of the wire at the transposition.

[0019] The following is an example of a double-single helical coil wound with 8 transposed wires in conjunction with the accompanying drawings:

[0020] Step 1. Put the reels on the wire reel stand according to the number of parallel wires required (8 wires), and arrange them in two rows. The arrangement of the wires is as attached image 3 . Two columns up and down, 4 wires in each row, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com