Flocculation central driving mud scraper

A central drive scraping and flocculation technology, applied in the sedimentation tank and other directions, can solve the problems of uneven water distribution, low operation efficiency of the whole machine, low treatment efficiency, etc., to save investment costs and land resources, good treatment effect, The effect of improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

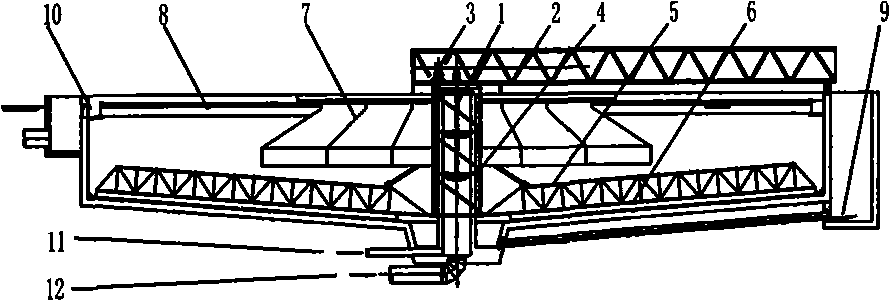

[0017] Such as figure 1 , 2 As shown, the present invention includes a central concrete support pier arranged in a circular sedimentation tank, a central rotating vertical frame 4, a transmission device 3, a scraper truss 5, a scraper 6, a working bridge 2, and sewage at the bottom of the pond Inlet pipe 12, sludge outlet 9, which also includes a conical flocculation reaction cylinder 7, a drug feed pipe 11 located at the bottom of the pool, a reaction mixer 1, the flocculation reaction cylinder 7 is fixedly connected to the working bridge 2, and the mixing mixer 1 is set On the central concrete pier, the mixing mixer 1 is located above the drug feed pipe 11 and the sewage inlet pipe 12, and the water outlet of the mixing mixer 1 faces the inner cone surface of the conical flocculation reaction cylinder 7.

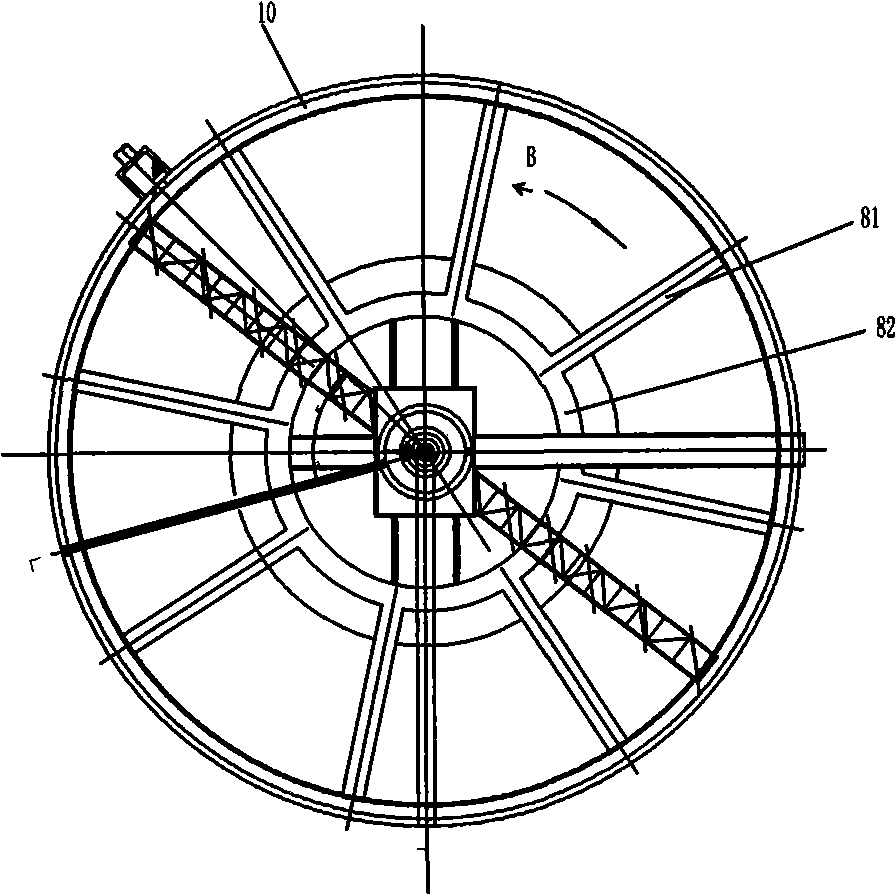

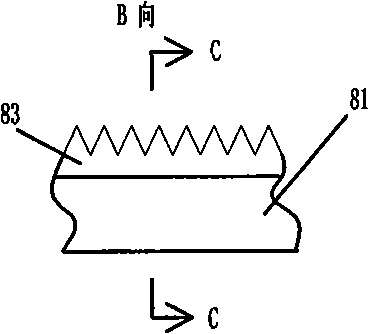

[0018] The present invention also includes such as image 3 , 4 Shown is the outlet tank 8 formed by the annular water tank 82 and the spoke-shaped water tank 81, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com