Method for preparing carboxymethyl modified starch

A technology of carboxymethyl starch and modified starch, which is applied in the field of modified starch, can solve the problems of agglomeration of reactants, high equipment requirements, uneven reaction, etc., and achieve the effects of improved reaction efficiency, shortened reaction time, and short reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

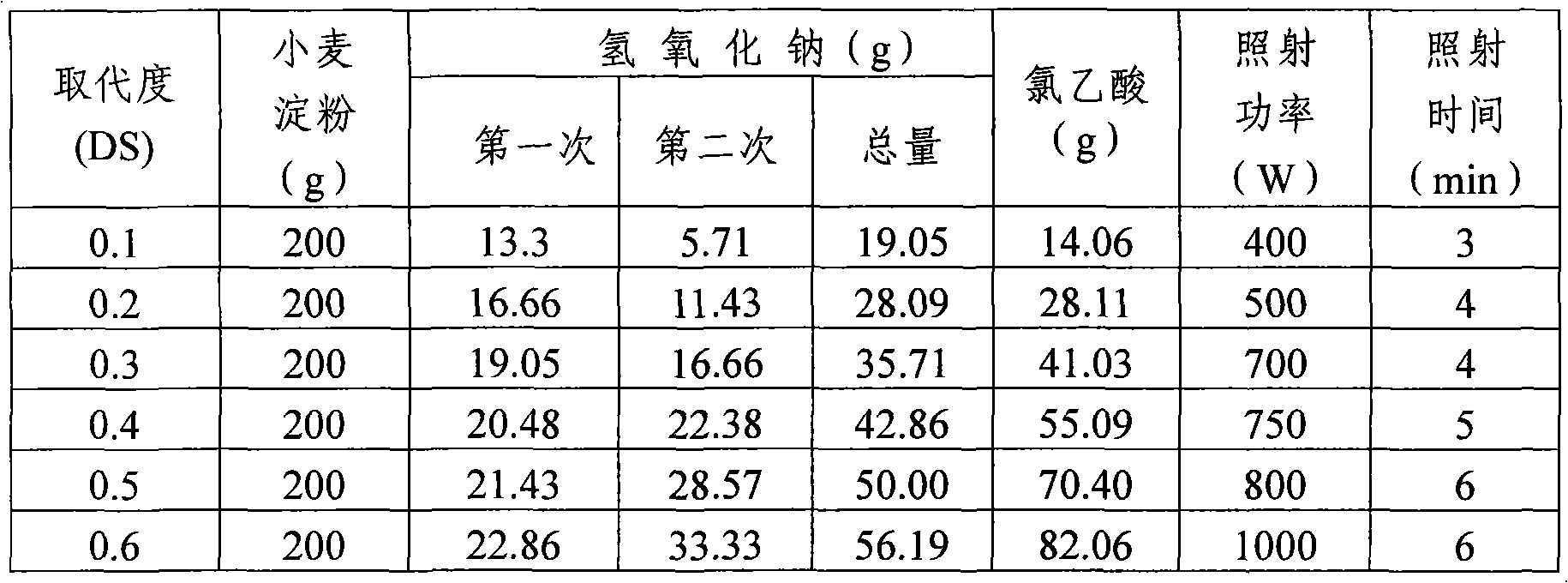

Image

Examples

Embodiment 1

[0025] 1. Reagent preparation:

[0026] ①Preparation of sodium hydroxide ethanol solution: place the container in a cold water bath, dissolve 20.48g sodium hydroxide in 21.5ml pure water, wait for it to dissolve, slowly add 53.9ml 95% ethanol, stir to make it complete Dissolve.

[0027] ②Preparation of sodium chloroacetate ethanol solution: Place the container in a cold water bath, and dissolve 22.38g of sodium hydroxide in 23.5ml of pure water. After it is dissolved, slowly add 58.8ml of 95% ethanol and stir to make it complete After dissolving, 55.09g of chloroacetic acid was slowly added to it, and stirred to complete the reaction.

[0028] 2. Operation method:

[0029] ① After mixing 312ml pure water and 488ml 95% ethanol, add 200g wheat starch (dry basis) under stirring, keep the stirring and the reaction vessel closed, maintain the temperature of the reaction system at 85℃, keep the speed of 40r / min, and stir React for 30 minutes, after the reaction is over, centrifuge and col...

Embodiment 2

[0035] 1. Reagent preparation:

[0036] ①Preparation of sodium hydroxide ethanol solution: place the container in a cold water bath, dissolve 57.15g of sodium hydroxide in 60ml of pure water, after it is dissolved, slowly add 150ml of 95% ethanol, stir to make it completely dissolved.

[0037] ②Preparation of sodium chloroacetate ethanol solution: Place the container in a cold water bath, and dissolve 83.33g of sodium hydroxide in 87.56ml of pure water. After it is dissolved, slowly add 219ml of 95% ethanol and stir to make it completely dissolved Then, 205.15g of chloroacetic acid was slowly added to it, and stirred to make it react completely.

[0038] 2. Operation method:

[0039] ① After mixing 780ml pure water and 1220ml 95% ethanol, add 500g potato starch (dry basis) under stirring, keep the stirring and the reaction vessel closed, maintain the temperature of the reaction system at 85℃, keep the speed of 40r / min, and stir React for 30 minutes, after the reaction is over, centri...

Embodiment 3

[0045] 1. Reagent preparation:

[0046] ①Preparation of sodium hydroxide ethanol solution: Place the container in a cold water bath, and dissolve 107.15g sodium hydroxide in 112.5ml pure water. After it is dissolved, slowly add 282ml 95% ethanol and stir to make it completely dissolved .

[0047] ②Preparation of sodium chloroacetate ethanol solution: Place the container in a cold water bath, and dissolve 142.85g sodium hydroxide in 150ml pure water. After it is dissolved, slowly add 375ml 95% ethanol and stir to make it completely dissolved. , And then slowly add 352 g of chloroacetic acid to it, stir to make it react completely.

[0048] 2. Operation method:

[0049] ① After mixing 1560ml pure water and 2440ml 95% ethanol, add 1000g corn starch (dry basis) under stirring, keep the stirring and the reaction vessel closed, maintain the temperature of the reaction system at 85℃, and stir the reaction at a speed of 40r / min 35min, after the reaction is over, centrifuge and collect the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com