Differential column-splitting inlet energy dissipater

An energy-dissipating, split-type technology, applied in water conservancy engineering, marine engineering, coastline protection and other directions, can solve serious problems, damage to the stilling pool structure, downstream river scouring, etc., to improve service life, improve stress conditions, reduce The effect of small scour damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The differential split-type imported energy dissipators in Embodiment 1 and Embodiment 2 are designed according to a large-scale hydropower station project with an installed capacity of 6400MW and a concrete gravity dam with a maximum dam height of 161m. The design flood (P=0.2%) flow rate of the hydropower station is 41200m 3 / s, check the flow of flood (P=0.02%) 49800m 3 / s, the maximum water level difference between upstream and downstream is 120m, and the maximum total discharge power is about 40000MW. The maximum single-width flow in the stilling pool is 225m 2 / s, the flow velocity of the stilling pool into the pool is about 40m / s.

[0040] Example 1

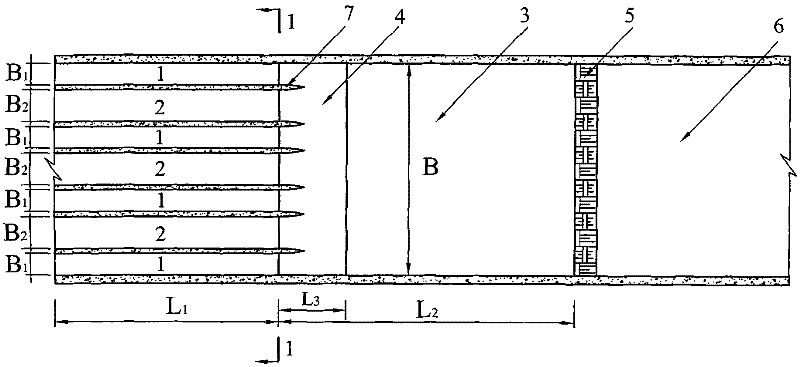

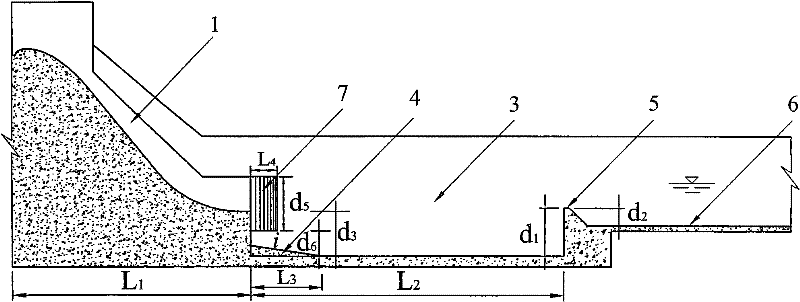

[0041] The structure of the differential split-type imported energy dissipator in this embodiment is as follows: figure 1 , image 3 , Figure 4 , Figure 7 As shown, it includes a water flow inlet section, a stilling basin 3 connected with the water flow inlet section, and an apron 6 connected with the still...

Embodiment 2

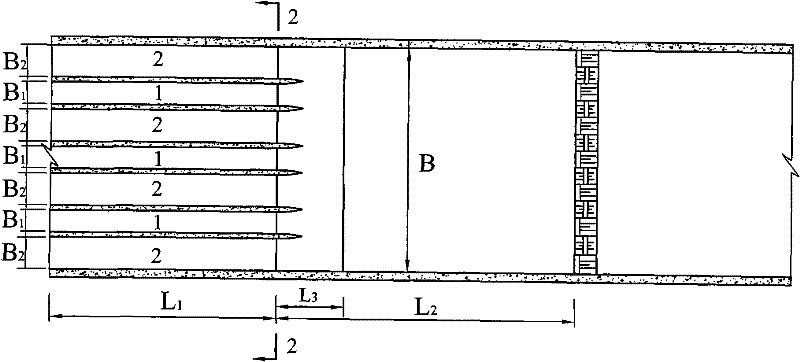

[0044] The structure of the differential split-type imported energy dissipator in this embodiment is as follows: figure 2 , image 3 , Figure 5 , Figure 10 As shown, it includes a water flow inlet section, a stilling basin 3 connected with the water flow inlet section, and an apron 6 connected with the stilling basin. The water flow inlet section is composed of high-level discharge grooves 1 and low-level discharge holes 2 arranged alternately. There are 3 high-level discharge grooves 1, 4 low-level discharge holes 2, and high-level discharge grooves 1 for non-pressure outflow, etc. Wide body type, the low discharge hole 2 is a pressure outflow, equal width body type. In the inlet section of the water flow, there is a foot 4 at the junction of the drop sill at the outlet end of the high discharge tank 1 and the outlet of the low discharge hole 2 and the bottom plate of the stilling pool. On the bottom plate of the pool, the sides perpendicular to the bottom surface in t...

Embodiment 3

[0046] The differential split imported energy dissipators in Embodiment 3 and Embodiment 4 are designed according to a large-scale hydropower station project with an installed capacity of 3000MW. The maximum dam height is 159m, and the design flood (P=0.2%) flow rate of the hydropower station is 17000m 3 / s, check the flow of flood (P=0.02%) 21000m 3 / s, the maximum water level difference between upstream and downstream is 120m, and the maximum total discharge power is about 40000MW. The maximum single-width flow in the stilling pool is 185m 2 / s, the flow velocity of the stilling pool into the pool is about 40m / s.

[0047] Example 3

[0048] The structure of the differential split-type imported energy dissipator in this embodiment is as follows: figure 2 , Figure 4 , Image 6 , Figure 12 As shown, it includes a water flow inlet section, a stilling basin 3 connected with the water flow inlet section, and an apron 6 connected with the stilling basin. The water flow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com