Delayed coking equipment for high-acid-containing raw oil and delayed coking method using same

A technology of delayed coking and raw oil, applied in the direction of coking carbonaceous materials, non-catalytic thermal cracking, cracking, etc., can solve the problems of short service life, impact, and increased costs, and achieve good economic benefits and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is used to illustrate the delayed coking equipment and delayed coking method provided by the present invention.

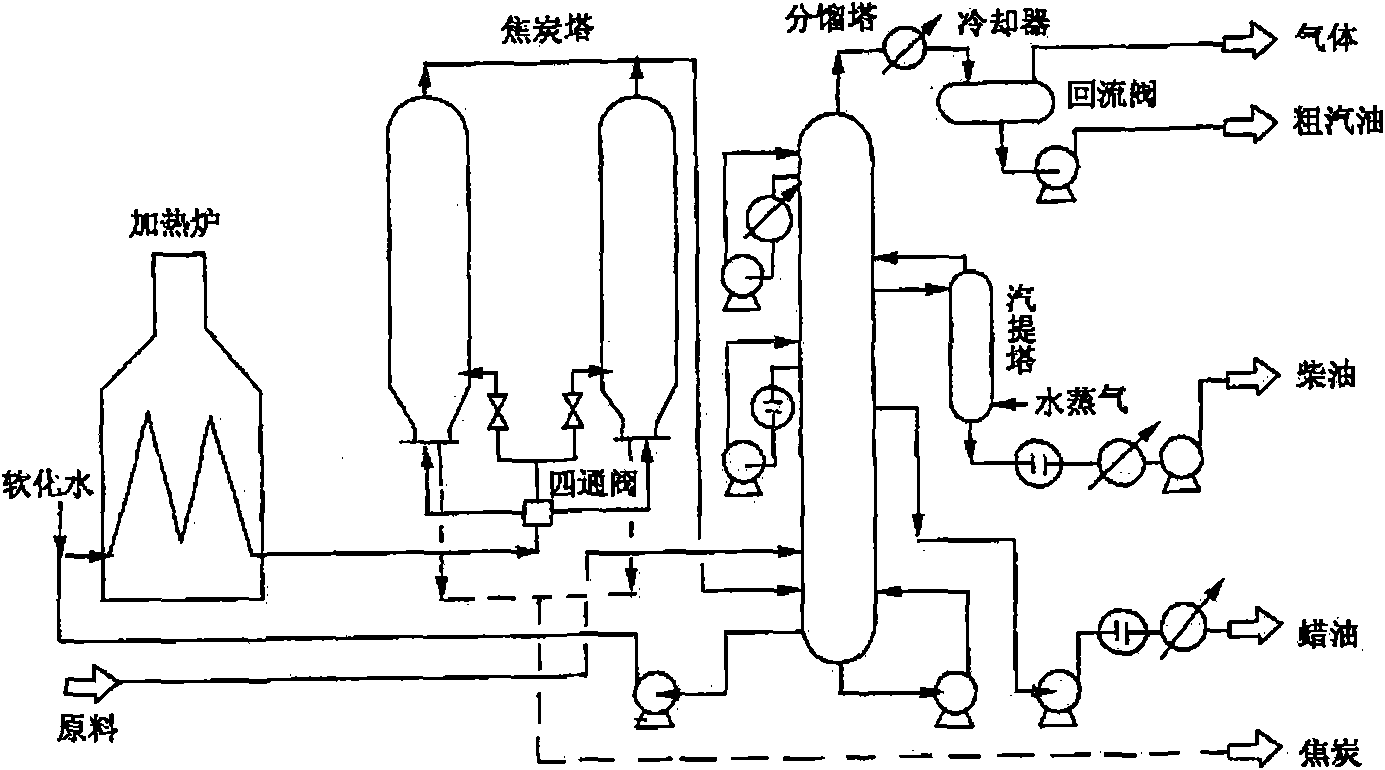

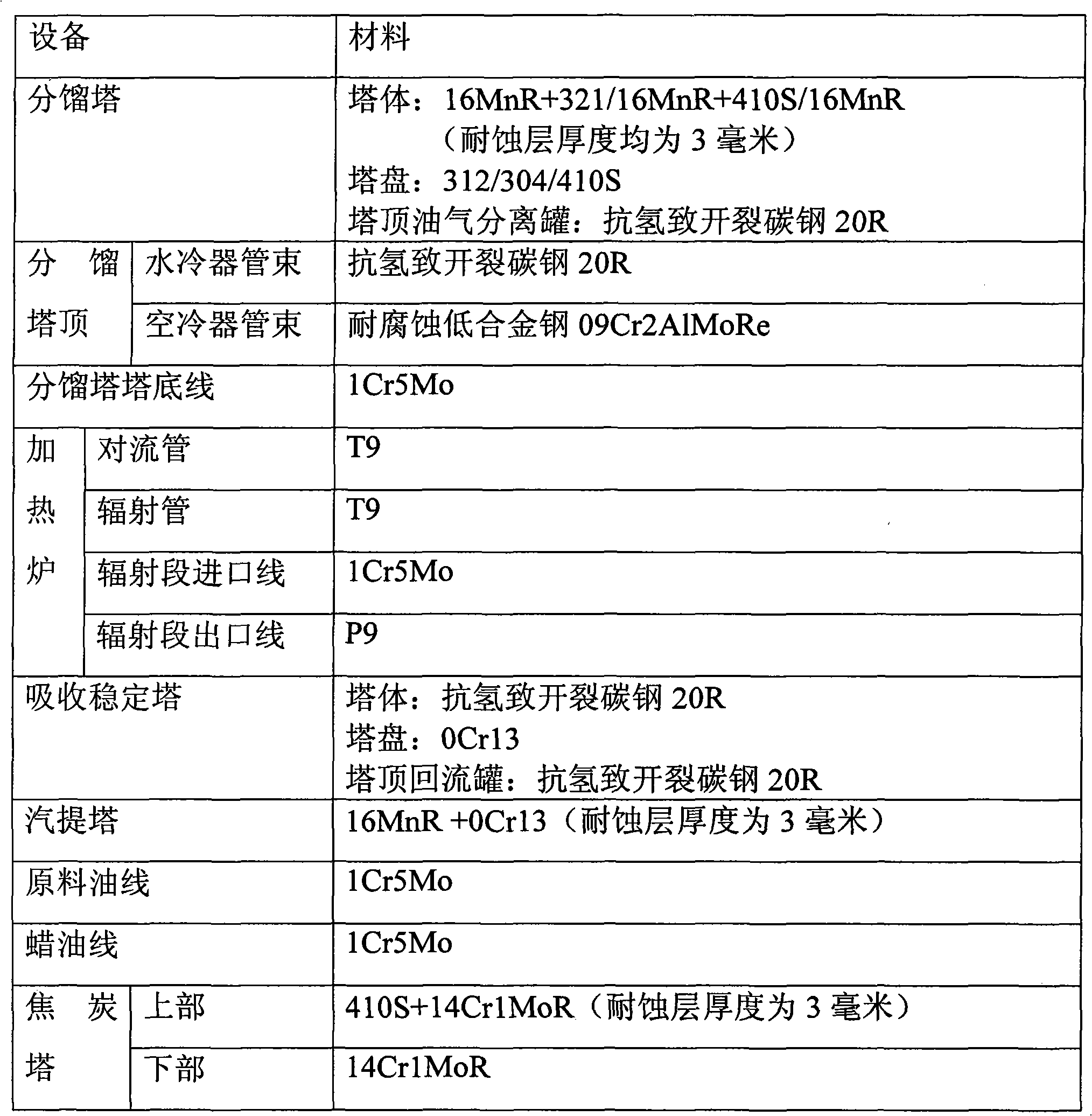

[0042] The "two furnaces and four towers" delayed coking equipment with a designed processing capacity of 4.2 million tons per year is adopted in accordance with the figure 1 The process shown is to carry out delayed coking on the vacuum residue (>560°C) after atmospheric and vacuum distillation of Penglai PL19-3 high-acid crude oil. One heating furnace is connected with two coke towers as a set, and one coke tower The coke tower is reacted and charged, and the other coke tower that has been charged is used for hydraulic decoking. The two coke towers are switched with a four-way valve, and they are operated in rotation according to the order of tower changing operations. The properties of the vacuum residue are shown in Table 2 below. The main operating conditions for delayed coking include that the operating pressure at the top of the coke t...

Embodiment 2

[0051] This embodiment is used to illustrate the delayed coking equipment and delayed coking method provided by the present invention.

[0052] Delayed coking was carried out on the high-acid feedstock oil according to the method in Example 1. The difference was that, except for the heating furnace, the materials of the other containers were all carbon steel 16MnR steel, and the materials of the pipelines were all 20# steel. After one year of continuous operation of the delayed coking equipment, the corrosion amount was tested according to the method on pages 13-16, Volume 35, Issue 4, 2006 of Shandong Chemical Industry. mm, the corrosion amount of the inlet line of the radiation section is 0.03 mm, the corrosion amount of the outlet line of the radiation section is 0.01 mm, the corrosion amount of the fractionation tower body is 1 mm, the corrosion amount of the tray is 1 mm, and the oil and gas at the top of the tower The corrosion amount of the separation tank is 1 mm, the ...

Embodiment 3

[0054] This embodiment is used to illustrate the delayed coking equipment and delayed coking method provided by the present invention.

[0055] Delayed coking was carried out on the high-acid feedstock oil according to the method in Example 1, the difference is that the acid value of the high-acid feedstock oil was 1.8 mgKOH / g, and the iron content was 40.56 μg·g -1 , The material of the convection tube and radiation tube of the delayed coking equipment is 321H, the material of the inlet line of the radiation section is 321, and the material of the outlet line of the radiation section is 316L.

[0056] After one year of continuous operation of the delayed coking equipment, the corrosion amount was tested according to the method on pages 13-16, Volume 35, Issue 4, 2006 of Shandong Chemical Industry. mm, the corrosion amount of the inlet line of the radiation section is 0.04 mm, the corrosion amount of the outlet line of the radiation section is 0.02 mm, the corrosion amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com