Concrete cut sampling machine

A sampling machine and concrete technology, applied in the direction of sampling devices, etc., can solve the problems of large labor consumption, large labor consumption, large labor consumption, etc., to ensure uniformity and accuracy, clean environment, and no dust pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

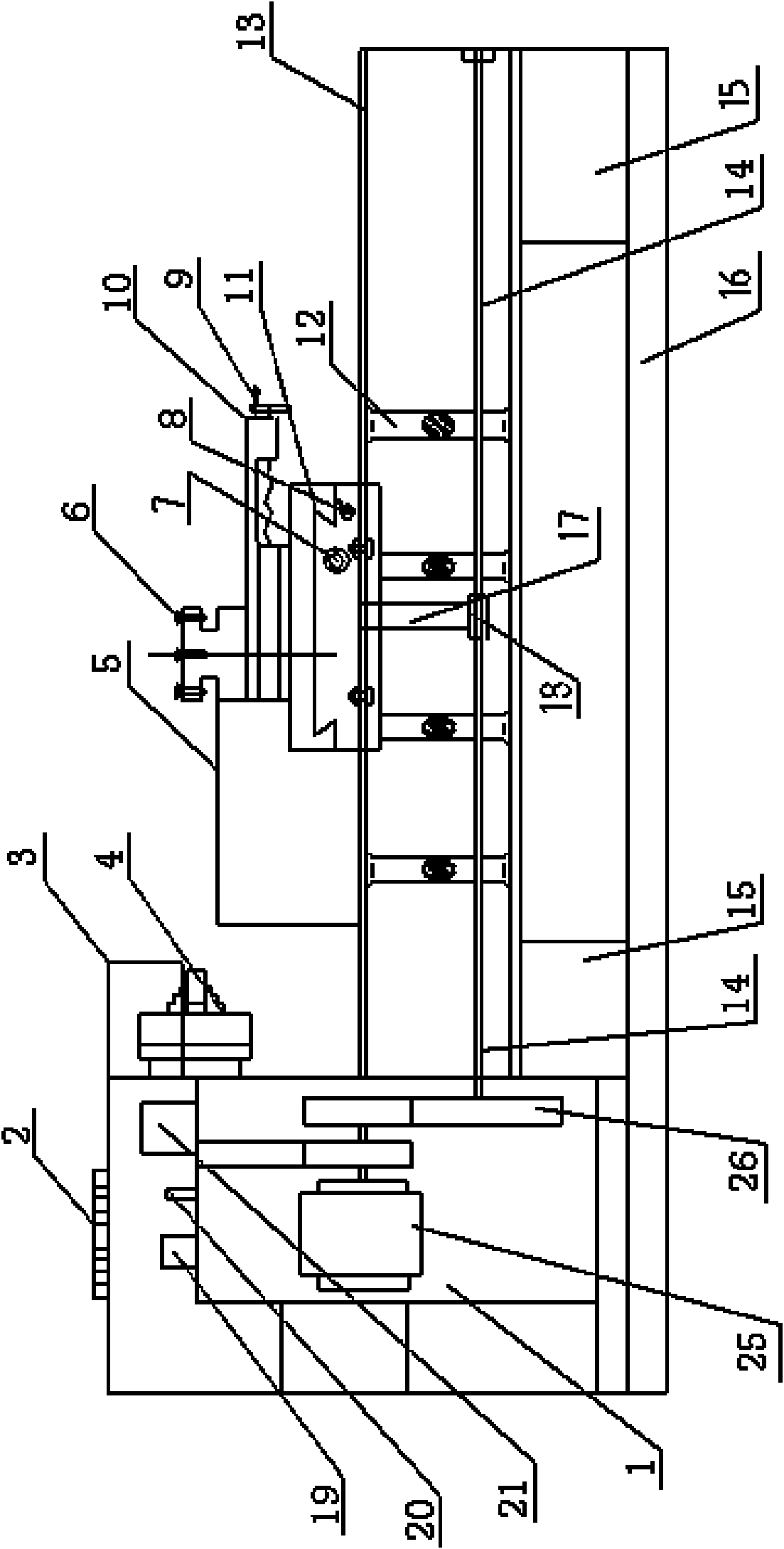

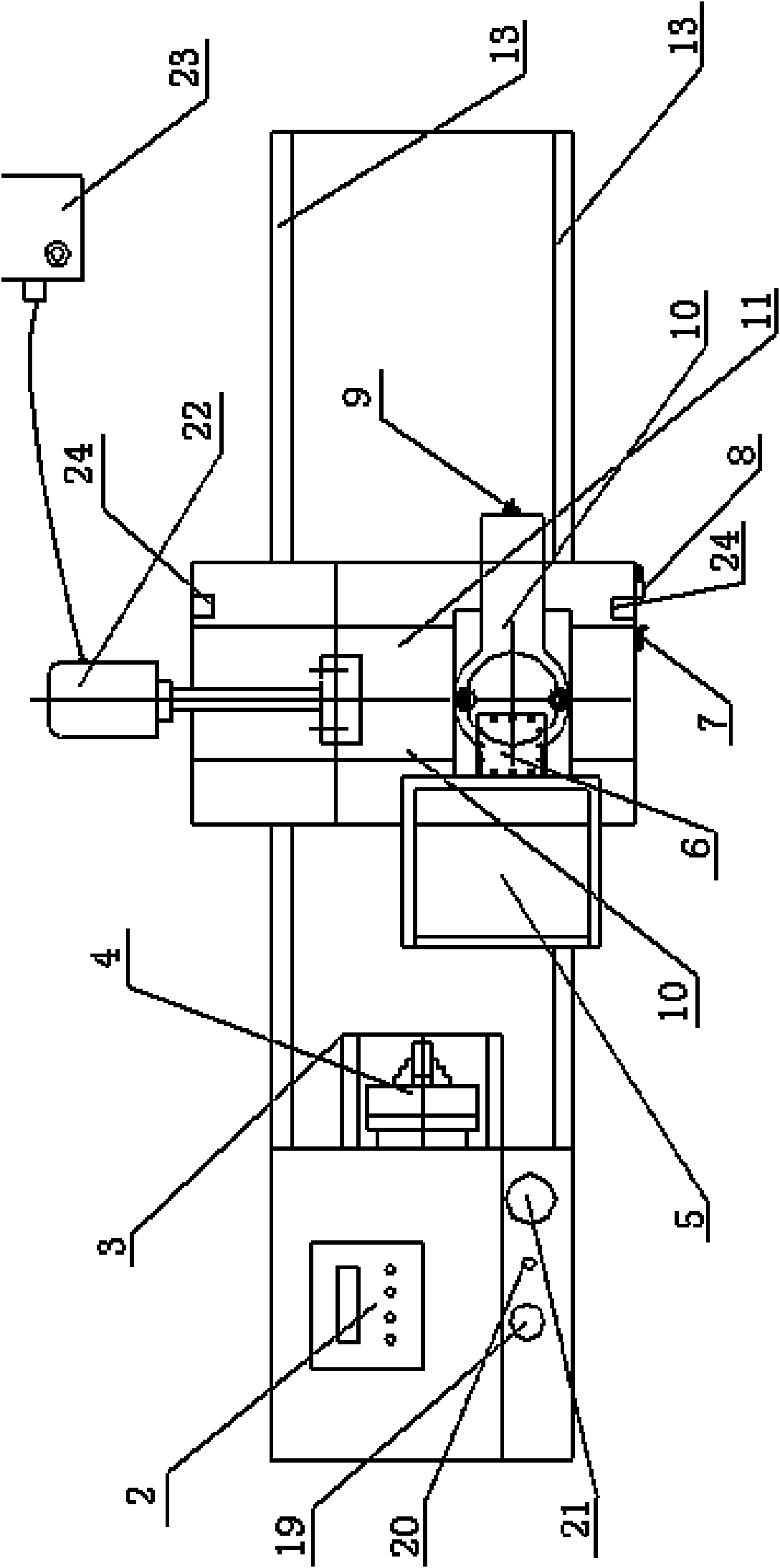

[0014] With reference to accompanying drawing: transmission case 1 is located on base 16, and transmission motor 25 and transmission gear group 26 are housed in the transmission case, and transmission motor 25 and transmission gear group 26 drive transmission screw mandrel 14 and test drive case 1 outside. The workpiece clamping chuck 4 rotates, the bed leg seat 15 is provided between the transmission screw rod 14 and the base 16, a dust cover 3 is provided outside the specimen clamping chuck 4, and two A guide rail 13, a bed support 12 is provided between the guide rail and the outrigger seat of the bed, the large carriage 11 on the guide rail is movably connected with the guide rail 13 through the transmission screw sleeve 8, and the large carriage 11 is connected to the transmission wire through the connecting handle 17 The rods are connected and controlled by the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com