Method for testing anti-cracking performance of cement base material

A technology of cement-based materials and anti-cracking performance, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve problems such as damage to the test piece, affect the results of the test, increase the test workload, etc., to improve the experimental accuracy, reduce labor, The effect of reducing variance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0017] A method for testing the crack resistance of cement-based materials in the present invention:

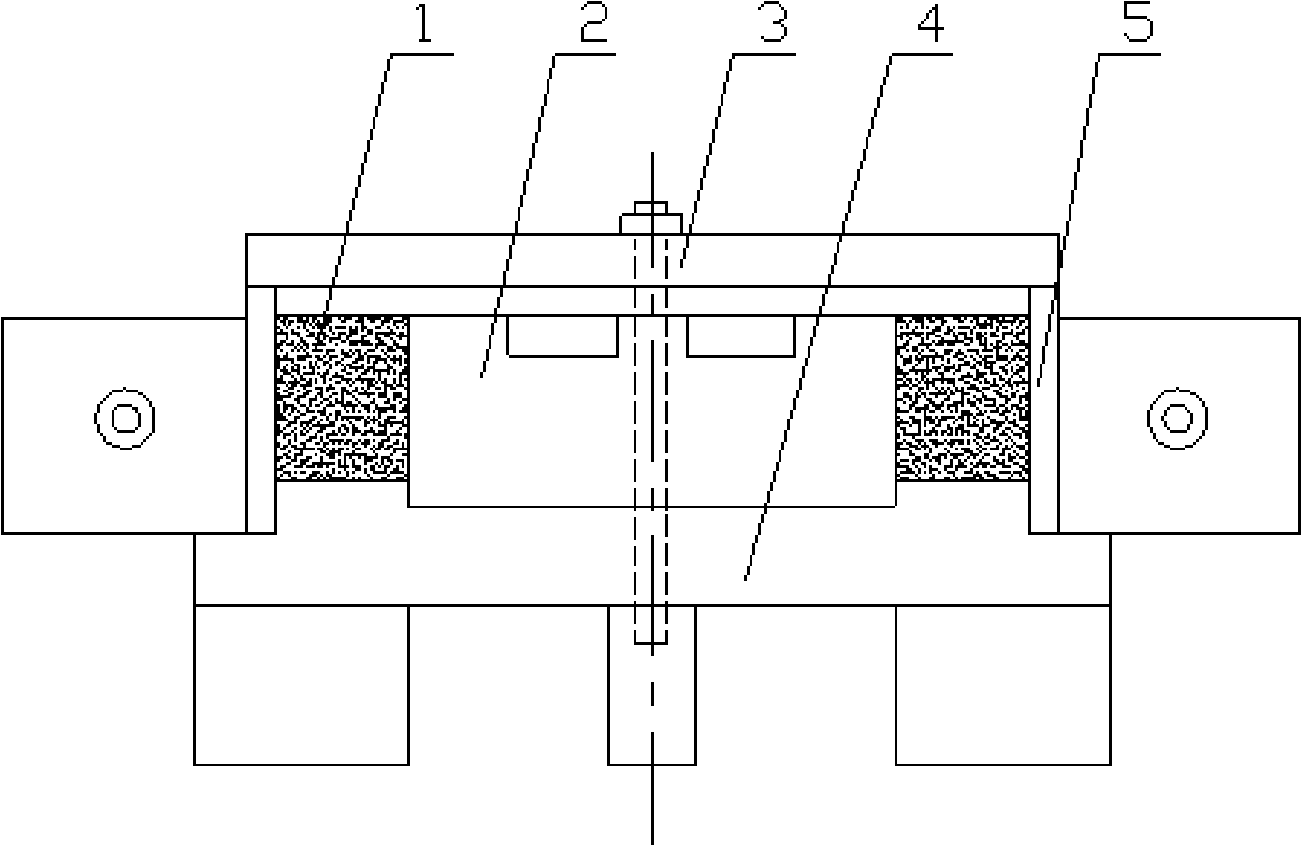

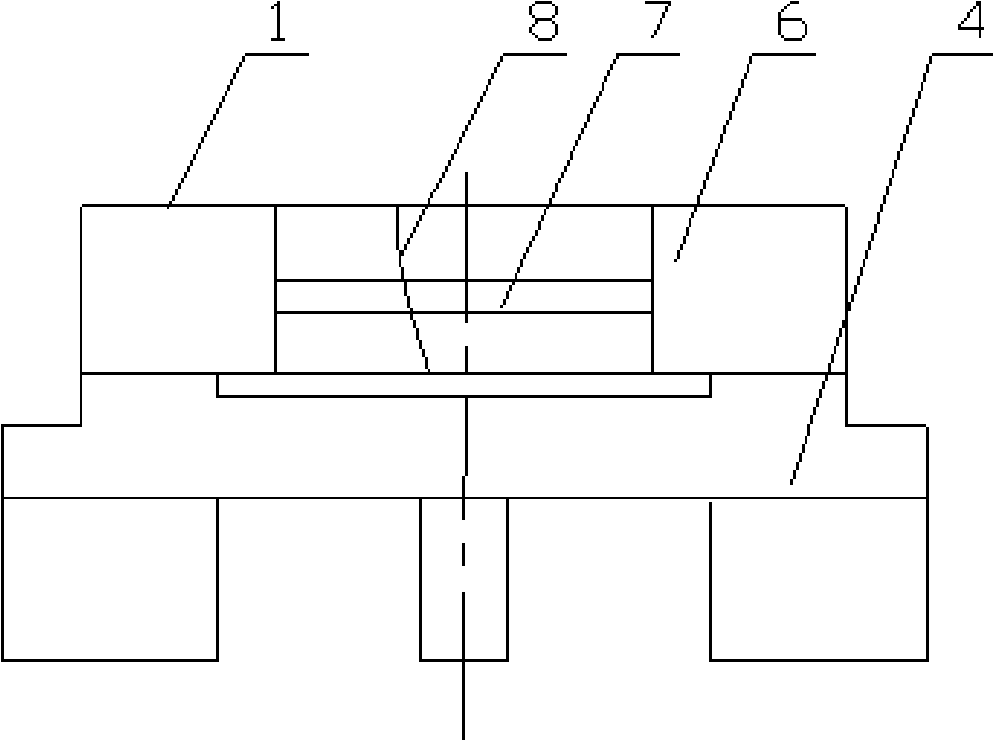

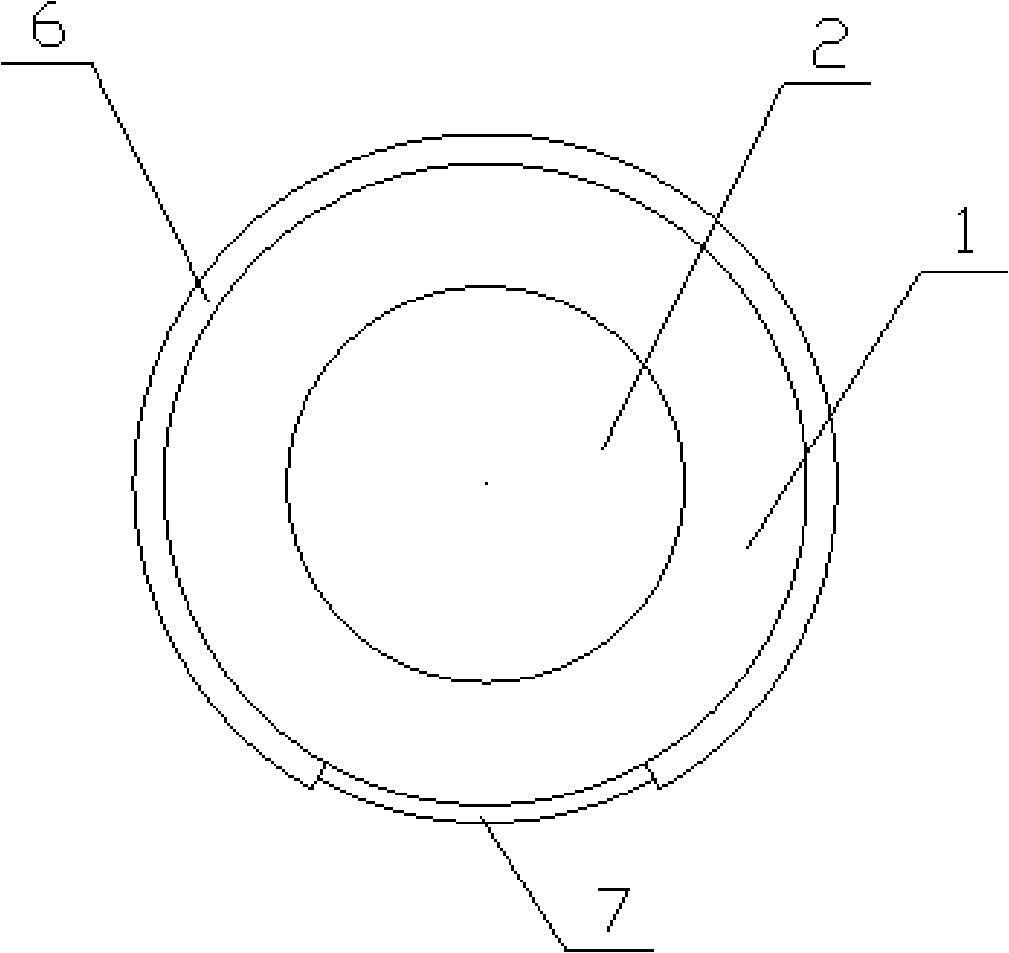

[0018] Before the test, a ring test piece 1 made of a plexiglass base 4, an upper cover 3, and a side mold 5 is adopted to make a ring test piece 1, as figure 1 shown. After the final setting of the test piece, the plexiglass upper cover 3 and the side mold 5 of the ring test mold are removed, and the outer circular surface of the test piece 1 is completely exposed. Apply sealant 6 to the interval, such as figure 2 and image 3 As shown, the water loss position of the ring test piece is limited by applying sealant, so as to control the humidity inside the test piece. Drying shrinkage occurs at the position, and the resulting strain is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com