Touch display panel, composition for forming sealant, and sealant

A display panel and sealant technology, applied in adhesives, non-polymer organic compound adhesives, data processing input/output processes, etc. Control quality display quality and other issues to achieve the effect of increasing touch sensitivity and excellent elastic recovery force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The content of each component in the composition used to form the sealant 250 is shown in Table 1. In this embodiment 1, bisphenol A type epoxy monoacrylate monomer has 33 weight percent, acrylic acid monomer has 8 weight percent, photoinitiator has 0.8 weight percent, hardener has 4 weight percent, bisphenol A The type epoxy diacrylate monomer has 23 weight percent and the filler has 27 weight percent.

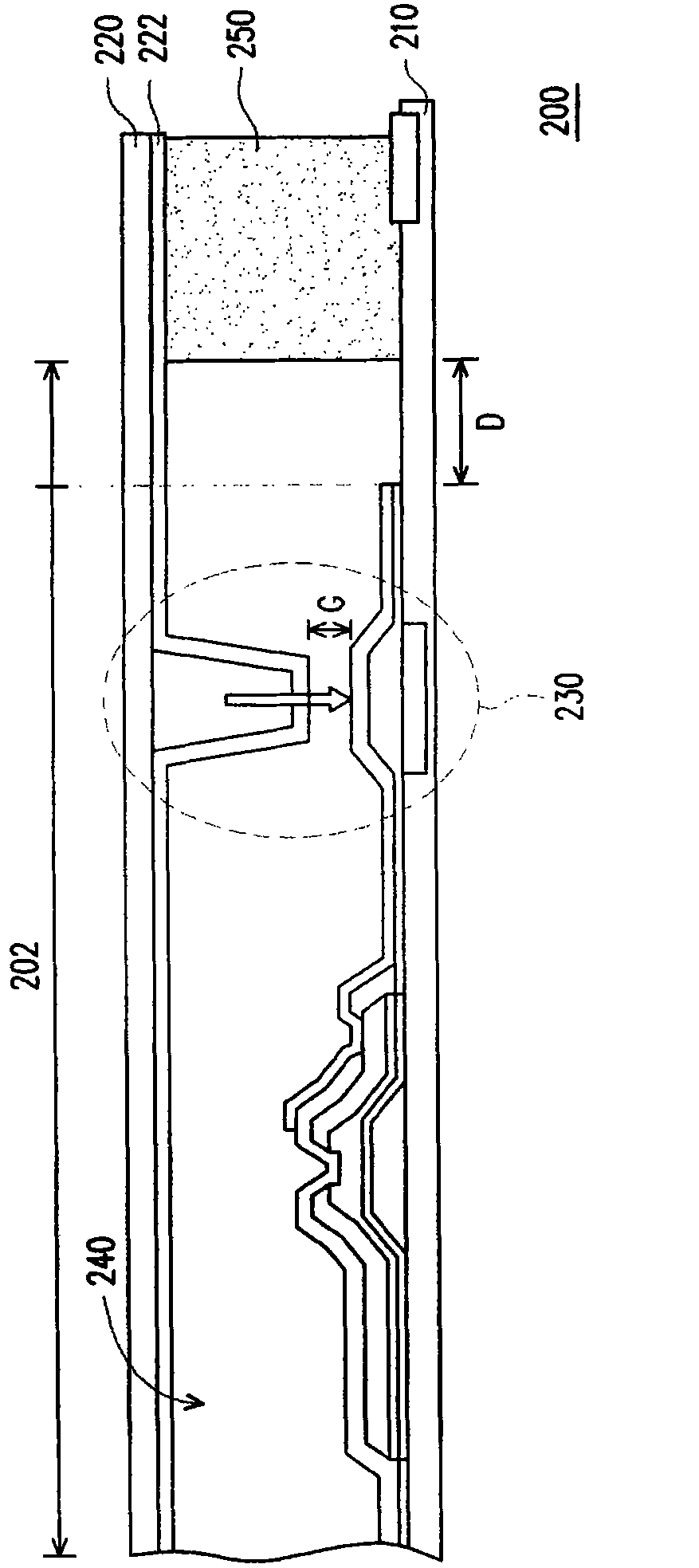

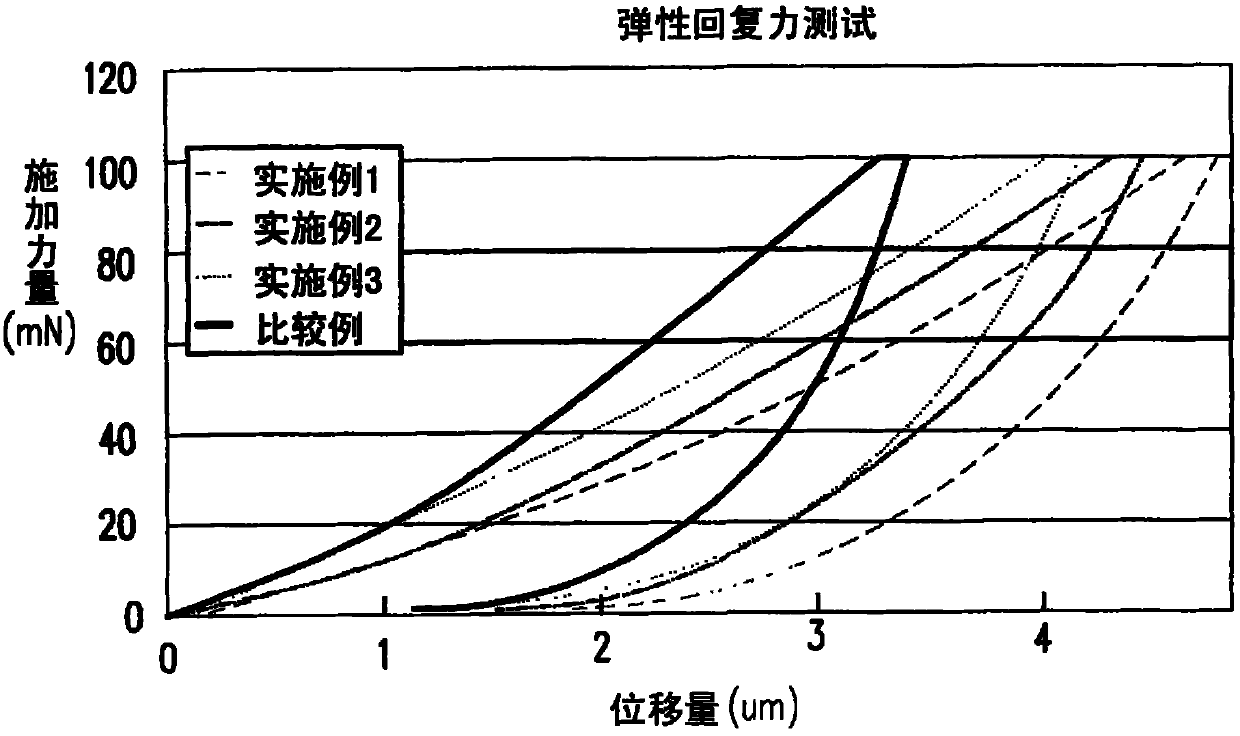

[0072] The polymer formed by the above composition after a polymerization reaction is used as the sealant 250 in the touch display panel 200 . The sealant 250 is subjected to an elastic recovery force test after light hardening and thermal hardening, wherein the conditions of the elastic recovery force test are: respectively apply different loads to the sealant 250, and measure the deformation of the sealant 250, the test The results are shown in Table 2 and figure 2 middle. And, let the displacement of the original state of the sealant 250 be zero when no force is...

Embodiment 2

[0076] The content of each component in the composition used to form the sealant 250 is shown in Table 1. In this embodiment 2, bisphenol A type epoxy monoacrylate monomer has 33 weight percent, acrylic acid monomer has 5 weight percent, photoinitiator has 0.5 weight percent, hardener has 4 weight percent, bisphenol A The type epoxy diacrylate monomer has 22 weight percent and the filler has 27 weight percent.

[0077] The polymer formed by the above composition after a polymerization reaction is used as the sealant 250 in the touch display panel 200 . The sealant 250 was subjected to an elastic recovery force test after light hardening and heat hardening, and the test results are shown in Table 2 and figure 2 middle. The conditions of the elastic recovery force test are the same as above, and according to the aforementioned calculation method of the elastic recovery force, the elastic recovery force RR of Example 2 is substantially 70.78%.

Embodiment 3

[0079] The content of each component in the composition used to form the sealant 250 is shown in Table 1. In this embodiment 3, bisphenol A type epoxy monoacrylate monomer has 33 weight percent, acrylic acid monomer has 2.5 weight percent, photoinitiator has 0.25 weight percent, hardener has 4 weight percent, bisphenol A The type epoxy diacrylate monomer has 30.5 weight percent and the filler has 27 weight percent.

[0080] The polymer formed by the above composition after a polymerization reaction is used as the sealant 250 in the touch display panel 200 . The sealant 250 was subjected to an elastic recovery force test after light hardening and heat hardening, and the test results are shown in Table 2 and figure 2 middle. The conditions of the elastic recovery force test are the same as above, and according to the aforementioned calculation method of the elastic recovery force, the elastic recovery force RR of Example 3 is substantially 64.45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com