High pressure and high power series thyristor self-cold and hot pipe radiator unit and method therefor

A heat pipe radiator and radiator group technology, which is applied in the fields of power semiconductor devices, power electronics, heat transfer and heat dissipation, can solve the problems of heavy heat pipe radiator, high radiator cost, and high price, and achieve compact structure and heat dissipation The effect of high efficiency and heat dissipation power and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

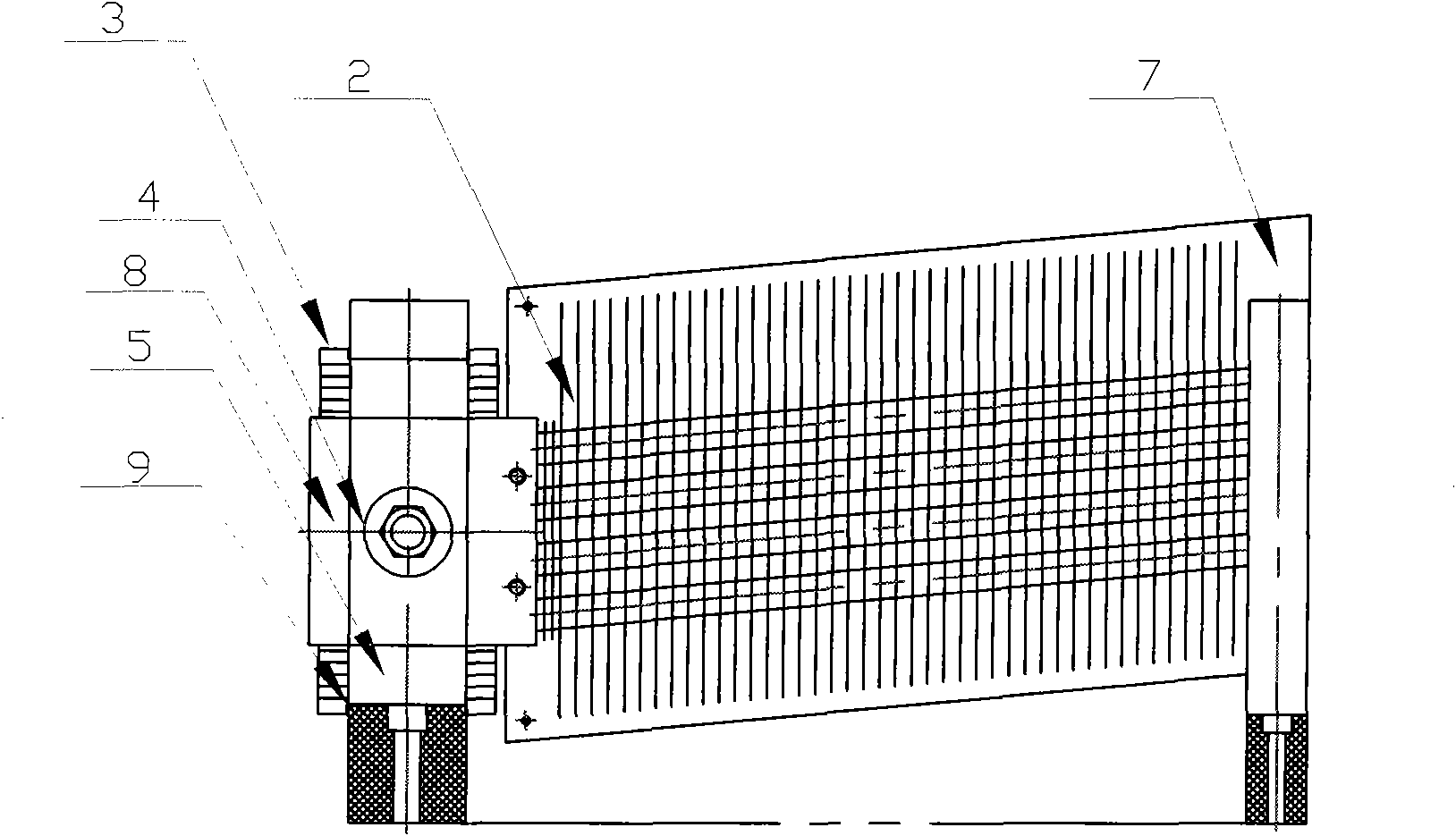

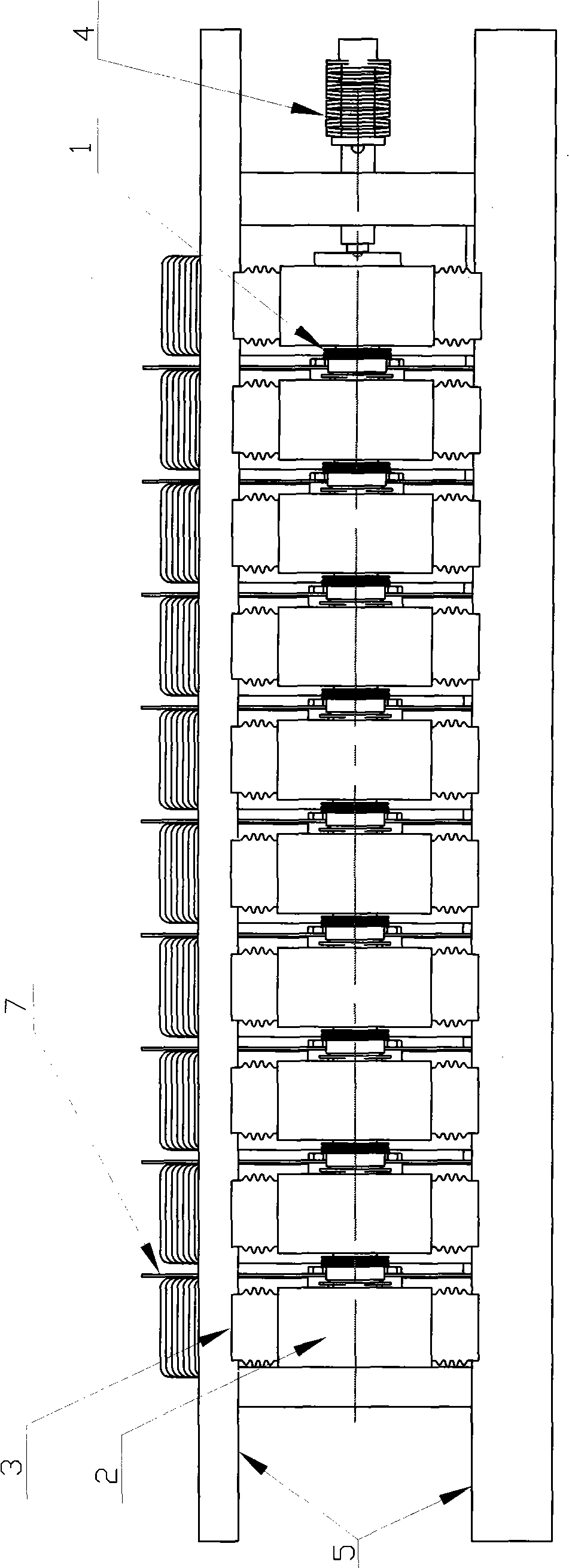

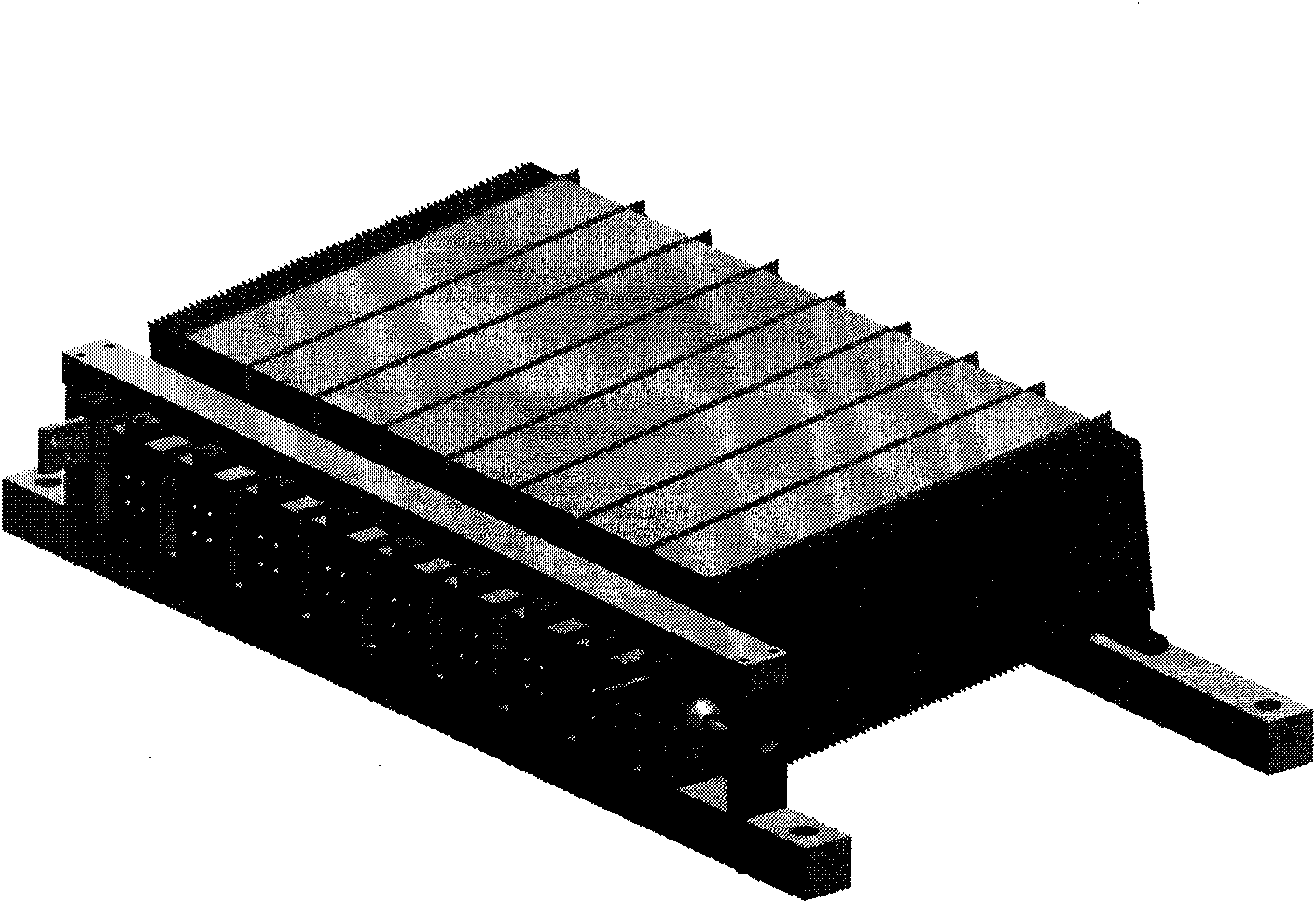

[0020] In the thyristor 1 connected in series, the heat pipe radiator and the thyristor are connected in series and crimped at intervals, which is characterized in that the overall structure is compact, and the attached high-voltage insulating crimping parts include: high-purity epoxy insulating plate 5, aluminum alloy at the end Metal block 6, insulating casting with insulating umbrella group fixed on the heat pipe radiator 2, top pressure mechanism 4, insulating partition 7 between the two heat pipe radiators 2, the above structure ensures that different types of thyristors are suitable for series crimping The crimping force and crimping concentricity reduce the contact thermal resistance between the thyristor and the heat pipe radiator substrate 8 to a lower level, and at the same time ensure that the overall high insulation characteristics of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com